Leave Your Message

The importance of a Butterfly Valve With Locking Device cannot be overstated. This valve is essential in various industries. It ensures safety and reliability while managing fluid flow.

With this valve, operators can secure the position easily. This feature helps in preventing accidental openings. Such a locking device adds an extra layer of protection. It is especially useful in high-pressure environments where safety is critical.

Users must assess their specific needs when selecting a Butterfly Valve With Locking Device. Not all valves are created equal. There are advancements and varying specs worth examining. Reflecting on these elements ensures a better decision. A well-chosen valve can improve system efficiency. It minimizes the risk of leaks and failures, a crucial factor in operational success.

Butterfly valves with locking devices play a crucial role in various industrial applications. These devices ensure safety and proper functioning by preventing accidental valve movement. A report from the Valves and Actuators Market Research states that the demand for butterfly valves is expected to grow significantly. Many industries prioritize secure and reliable systems, making these valves essential.

Locking devices enhance the performance of butterfly valves. They provide an added layer of security against unauthorized access. When a valve is in a closed or open position, the locking device secures it, reducing the risk of leaks or accidents. The American National Standards Institute (ANSI) suggests regular inspections to ensure locking mechanisms are functioning correctly. Regular maintenance can prevent future issues.

Tips: Always check the locking device for signs of wear. Replace any damaged parts promptly. Ensuring proper function can save time and costs down the line. Additionally, proper training for personnel handling these valves is vital. It helps to minimize errors and enhance safety protocols. The integration of locking devices is a step toward more secure and efficient operations.

When selecting the best butterfly valves for 2026, key features command attention. One significant aspect is the locking device, which enhances safety. This mechanism ensures that the valve remains securely closed, preventing accidental leaks. In hazardous environments, this feature becomes essential.

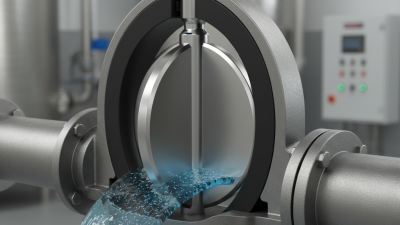

Another important characteristic is the material of construction. Many valves use durable materials that withstand high pressures and corrosive substances. This increases longevity and reliability. Users also often overlook the ease of installation. Some designs simplify the process, reducing time and costs.

Performance metrics matter too. The flow rate can significantly impact system efficiency. Valves that provide smooth operations reduce the risk of turbulence. However, not all models achieve this balance seamlessly. It prompts users to reflect on their specific needs. Quality varies widely, and understanding these nuances is crucial before making a final decision.

Locking devices in butterfly valves provide essential safety and operational benefits. These devices prevent unauthorized access and unintended operation of valves, which is crucial in industries such as oil and gas. According to the Valve Manufacturers Association, approximately 70% of valve failures relate to human error. This highlights the need for effective locking mechanisms.

Moreover, the implementation of locking devices can significantly reduce accidents. Data shows that facilities equipped with locking devices experience 30% fewer incidents related to valve mismanagement. This proactive approach not only protects personnel but also enhances equipment longevity. In environments where pressure fluctuations are common, reliable locking features ensure that valves remain in their intended position, mitigating potential hazards.

However, not all locking devices are created equal. Some may be prone to wear and tear, reducing their effectiveness over time. Maintenance becomes a consideration that users must address. Regular inspections are necessary to ensure locking mechanisms function properly. Without due diligence, the benefits of these safety features could falter, exposing facilities to risks they sought to mitigate. Users must balance the efficiencies and challenges that locking devices present in their operations.

Butterfly valves are essential in various industries. They regulate flow and control pressure in pipelines. Their design offers lightweight solutions for heavy-duty applications. Many sectors utilize these valves, including water treatment, oil and gas, and food processing. According to a recent industry report, the global valve market is projected to reach $93.5 billion by 2026. Butterfly valves are a significant part of this growth due to their efficiency.

In water treatment, butterfly valves help manage flow rates. They prevent backflow in sewage systems. The food industry uses them for hygienic processes. However, improper installation can lead to leaks. It’s crucial to follow best practices when installing these valves. Regular maintenance ensures long-term functionality.

**Tip:** Always verify the specifications before purchasing a butterfly valve. Choose a model that meets your application’s pressure and temperature requirements. Remember, even the best valve won't perform well if it's not suited for the job. Be careful about installation, as mistakes can be costly.

Proper maintenance and care of butterfly valves with locking devices are essential for ensuring their longevity and optimal performance. Regular inspections can prevent costly failures. According to industry data, neglected butterfly valves can reduce system efficiency by up to 20%. Every few months, operators should check the locking mechanism for wear and functionality. A simple visual inspection can reveal problems before they escalate.

Cleaning is also an important part of care. Dust and debris can accumulate over time. Keeping the valve clean can enhance its performance. Using a soft brush or cloth to remove buildup can significantly improve operation. Additionally, lubricating moving parts every six months can prevent stiffness. Neglecting lubrication can lead to increased friction and wear.

While these tasks seem straightforward, many operators overlook them. This oversight can shorten the valve’s lifespan. A report indicated that 30% of valve failures are due to inadequate maintenance. Understanding these factors is crucial for ensuring reliability. A consistent maintenance schedule can mitigate risks and enhance the reliability of butterfly valves.