Leave Your Message

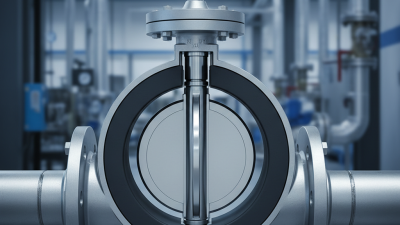

The Ebonite Lining Butterfly Valve is gaining attention in various industries for its unique advantages. Renowned expert Dr. Jane Smith, a leading authority in fluid control technology, states, "The Ebonite Lining Butterfly Valve provides exceptional durability and resistance in harsh environments." This statement reflects the rising demand for reliable valves that can withstand extreme conditions.

In recent years, the Ebonite Lining Butterfly Valve has become essential for many applications. Its ability to prevent corrosion makes it a top choice for industries such as chemical processing and water treatment. The valve's design features a high-performance sealing mechanism, ensuring minimal leakage and enhanced efficiency.

However, not all Ebonite Lining Butterfly Valves are created equal. Some users report challenges with maintenance and installation. The learning curve for proper usage can be steep. These factors remind us that even advanced technology requires careful consideration and understanding. Exploring both the benefits and potential downsides is crucial for making informed decisions.

Ebonite lining in butterfly valves provides significant advantages. This material offers excellent resistance to wear and corrosion. It proves valuable in various industries, especially chemical processing. Ebonite is a rubber-like substance, often used to enhance valve longevity. This lining ensures that the valves function well even under harsh conditions.

However, there are some challenges with ebonite lining. Over time, exposure to certain chemicals can degrade the lining. Regular inspection is essential to ensure optimal performance. Users sometimes overlook the importance of this maintenance. Additionally, improper installation can lead to premature failure. This reflection highlights the need for proper training when handling ebonite-lined valves.

Despite these issues, the benefits often outweigh the negatives. Enhanced sealing and reduced leakage are noteworthy. Ebonite lining improves flow control, which adds to efficiency. With careful usage, these valves can significantly improve system reliability.

The chart above illustrates the various benefits of Ebonite lining in butterfly valves, rated on a scale from 1 to 10. Key features include high corrosion resistance and durability, making it a preferred choice in many industrial applications.

The 2026 Best Ebonite Lining Butterfly Valve offers significant advantages for industrial applications. These valves are designed for durability and resistance to corrosive substances. Ebonite lining enhances their performance in harsh environments. According to industry reports, these valves can withstand pressures up to 150 psi. This makes them ideal for various fluid handling scenarios.

One key feature is their low torque operation. This reduces wear on the actuator, increasing the valve's lifespan. Users benefit from less energy consumption as well. The ease of installation is another plus. Fewer components mean reduced assembly time. This efficiency can save companies both time and money.

Tip: Regular maintenance can enhance valve longevity. Inspect seals for wear regularly.

It's worth noting that while ebonite-lined valves offer many benefits, they may not be suitable for all applications. Certain fluids can potentially degrade the lining over time. Always consult technical specifications. User feedback has highlighted that the adaptability of these valves can sometimes be limited in extreme conditions. Balancing performance and application is crucial for reliability.

Ebonite lining offers significant advantages in valve performance and durability. This material is known for its outstanding resistance to abrasion and corrosion. In industries like oil and gas, ebonite's durability is crucial. Studies indicate that ebonite-lined valves can last up to 30% longer than traditional materials. This can lead to substantial savings in maintenance costs.

Moreover, ebonite provides a low-friction surface. This characteristic minimizes wear and tear during operation. For instance, in high-temperature applications, ebonite maintains its integrity. It withstands extreme conditions better than many alternatives. However, the initial investment in ebonite-lined valves may be higher. Yet, the return on investment often proves worthwhile over time.

Another vital aspect is the ease of installation and compatibility with existing systems. Ebonite can adapt to various types of fluids, ensuring efficient operation. However, some challenge arises when integrating these valves in older setups. Engineers must carefully assess compatibility to avoid potential issues. In summary, ebonite lining enhances valve efficiency and longevity, but practical considerations must guide its application.

Ebonite lining butterfly valves are increasingly favored in various industries due to their unique properties. Their resistance to corrosive substances makes them ideal for chemical processing plants. A recent industry report highlights that approximately 30% of operational failures in plants stem from poor valve selection. Ebonite's resistance to wear and tear can significantly reduce maintenance costs. This attribute is crucial in applications where downtime leads to substantial financial losses.

These valves find extensive use in wastewater treatment. According to research, over 50% of water treatment facilities report valve-related issues each year. Ebonite-lined valves can withstand harsh conditions, contributing to improved reliability. This reliability aligns with industry needs for sustainability and waste reduction. Additionally, ebonite’s non-stick properties aid in effective flow management, further enhancing system efficiency. However, it's important to note that selecting the right valve requires careful consideration of the specific application and environmental factors.

In the oil and gas sector, the benefits of ebonite lining are also noteworthy. The material’s ability to resist high temperatures and pressures is beneficial in high-stakes environments. Yet, some professionals caution that while ebonite is robust, it may not suit all types of fluids. A comprehensive understanding of fluid dynamics is necessary. This knowledge can prevent costly mistakes in valve selection.

Maintaining ebonite lining butterfly valves is essential for their longevity and performance. Regular inspection is critical. Check for wear and tear. Look for cracks or peeling in the ebonite lining. This material can degrade over time due to chemical exposure. Daily use can lead to unexpected damage, affecting functionality.

Cleaning is equally important. Use mild detergents with warm water. Avoid harsh chemicals that could harm the ebonite. Ensure all moving parts are free of debris. Oil the hinges gently. This simple task can prevent rust and extend the valve’s life. If you notice unusual noises or resistance, it’s time for a deeper inspection.

Proper storage is crucial too. Store valves in a dry, cool place. Excessive heat can warp the lining. During off-seasons, check the valves periodically. This helps catch issues before they worsen. Reflecting on overall care practices can lead to better outcomes. Sometimes, we overlook these details, which can lead to more significant problems later.