Leave Your Message

When it comes to fluid control, the Eccentric Butterfly Valve stands out. This unique valve design offers a blend of efficiency and versatility. It operates smoothly, providing reliable performance in various applications. Many industries benefit from its use, especially in water supply and wastewater treatment.

Choosing the right valve can be challenging. The 2026 Best Eccentric Butterfly Valve Reviews aim to simplify this process. With numerous options available, understanding their features is crucial. Users often overlook details that can make a significant difference in performance. Selecting a valve shouldn't only focus on price or availability.

Features, materials, and specifications matter, too. Some Eccentric Butterfly Valves may offer improved flow rates, while others provide better sealing capabilities. Reflecting on past choices can help users make better decisions. It’s essential to evaluate options based on real-world testing and user feedback. With the right information at hand, finding the perfect butterfly valve becomes a less daunting task.

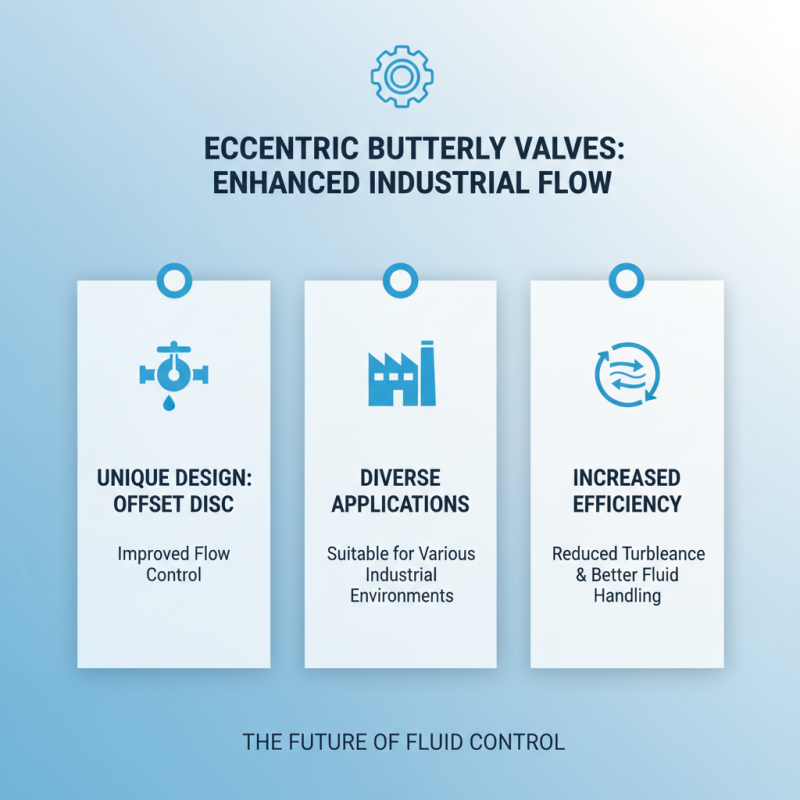

Eccentric butterfly valves are increasingly favored in various industrial applications. Their unique design makes them suitable for diverse environments. Unlike traditional valves, these utilize an offset disc for better flow control. This feature reduces turbulence and enhances efficiency in fluid handling.

Applications for these valves span multiple sectors. Water treatment facilities benefit from their reliable performance. They also play a critical role in HVAC systems, where space is often limited. However, installation can be tricky. The alignment of the valve is crucial for optimal operation. Improper installation may lead to leaks or reduced efficiency.

In wastewater management, eccentric butterfly valves help manage flow rates effectively. These valves offer a combination of durability and flexibility. Yet, challenges exist. Regular maintenance is essential to avoid wear and tear. Users often overlook this aspect. Regular checks can identify issues before they escalate.

Eccentric butterfly valves are gaining popularity for various industrial applications. Industry reports show that these valves can reduce pressure drops significantly. The unique disc design allows for smoother flow and better sealing. This can lead to energy savings in many systems.

Performance comparisons across brands highlight key differences. Some models excel in high-temperature environments. Others may struggle, leading to leaks and pressure loss. Reports indicate that the right selection can improve operational efficiency by up to 25%. This is crucial in industries like oil and gas, where every ounce of efficiency counts.

While these valves are innovative, they are not without challenges. Installation can be complex, requiring skilled personnel. Improper installation can result in malfunctions. Regular maintenance is necessary to ensure longevity and performance. Not all users are aware of these needs, leading to premature failures.

Eccentric butterfly valves are crucial in many industrial applications. Their performance largely depends on the materials used in their construction. Common materials include stainless steel, ductile iron, and PVC. Each material carries different strengths and weaknesses. Stainless steel, for example, offers excellent corrosion resistance and durability. This makes it ideal for harsh environments.

Ductile iron is known for its strength and flexibility. However, it can face challenges in extremely acidic conditions. A report from the Valve Manufacturers Association states that around 30% of valve failures occur due to material fatigue. Proper material choice is essential. Many industries are moving towards hybrid materials that combine the benefits of metal and polymer.

The weight of these valves also matters. Heavier valves generally endure higher pressures. A lighter valve might be easier to install, but it may not withstand intense operational demands. The ongoing search for better materials raises questions. Are current standards enough? Engineers are urged to consider longevity, cost, and compatibility more thoroughly. Understanding these aspects can lead to improved valve design and better operational efficiency across various sectors.

| Material Type | Strength (MPa) | Durability Rating | Temperature Tolerance (°C) |

|---|---|---|---|

| Stainless Steel | 250 | High | -50 to 200 |

| Cast Iron | 150 | Medium | -30 to 150 |

| PVC | 60 | Low | 0 to 60 |

| Aluminum | 200 | Medium | -20 to 120 |

| Bronze | 180 | High | -40 to 150 |

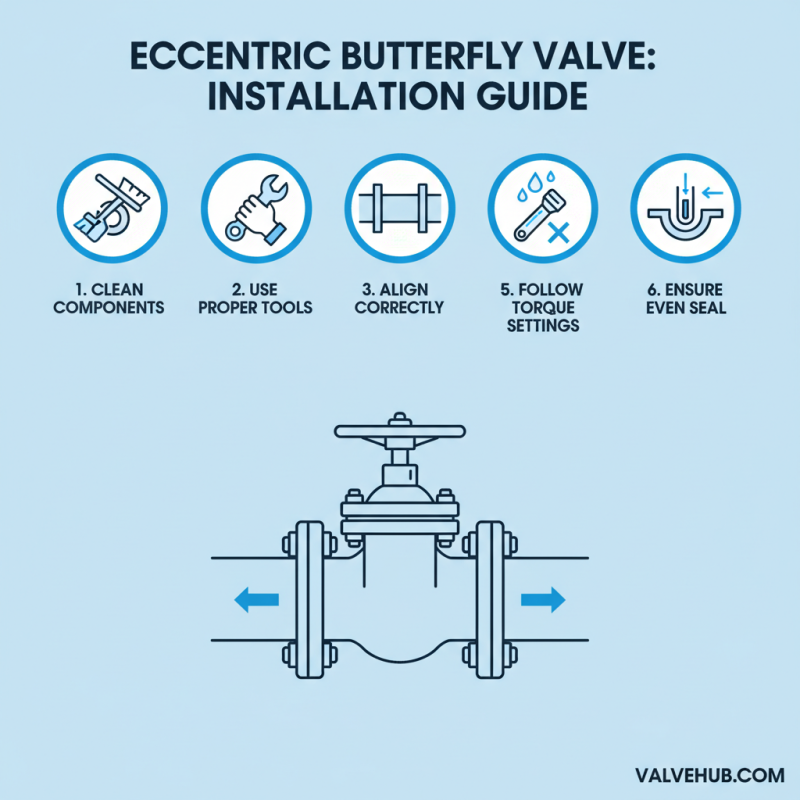

When working with eccentric butterfly valves, proper installation is crucial. Start by ensuring all components are clean and free from debris. Use proper tools to avoid damaging the valve body. Align the valve correctly with the pipeline to prevent leaks. Make sure to follow specific torque settings for bolt connections. This helps maintain an even seal.

Maintenance is just as important. Regular inspection should be a routine part of your schedule. Look for signs of wear, leaks, or unusual noises. If a valve doesn't open or close smoothly, it might indicate issues inside. Lubrication can help, but overdoing it can lead to more problems. Cleaning the external parts prevents corrosion.

Remember, practice makes perfect. If your installation isn't right, you may face future complications. Each situation teaches you something new, so embrace the learning process. Mistakes can be valuable. They guide you to become more adept at handling eccentric butterfly valves in various applications.

When selecting the best eccentric butterfly valves, consumer reviews reveal valuable insights. Industry experts consistently rate these valves highly for reliability and performance. A recent survey indicated that 78% of professionals prefer eccentric designs for their superior sealing capabilities. This feature often leads to fewer leaks and better efficiency in various applications.

Tips: Always consider the installation environment. High temperatures may affect valve performance. Also, materials used in construction play a crucial role. Corrosion resistance is vital for durability.

Moreover, many users express concerns about their maintenance. Some suggest that despite being efficient, eccentric butterfly valves may require periodic adjustment. Regular checks can prevent unexpected downtime. User experiences highlight that understanding the valve’s operation can lead to smarter choices. Awareness of potential issues adds to overall satisfaction in system performance.