Leave Your Message

The world of industrial valves is evolving. Among these, the En1074 Butterfly Valve stands out. This valve design is gaining traction across various sectors. Its compact structure and efficient operation are key attributes. Users appreciate its lightweight nature, making installation easier.

The En1074 Butterfly Valve is not without challenges. Some users report issues with sealing performance. These problems can arise from installation errors or low-quality materials. Addressing these concerns is vital for manufacturers. They must ensure high standards and rigorous testing.

Innovations in materials and technology are reshaping this valve category. Better materials promise enhanced durability and performance. Yet, the industry must reflect on balancing cost with quality. As demand grows, fluctuations in supply chains could complicate matters. This balance is crucial for sustaining interest in the En1074 Butterfly Valve moving forward.

The EN1074 butterfly valve market is evolving rapidly. In 2026, industry trends point towards increased demand for lightweight materials. According to a recent study, the use of composite materials in valve manufacturing is expected to rise by 25% over the next few years. This shift allows for improved performance and easier installation.

Sustainability is another focal point. Many manufacturers are prioritizing eco-friendly production methods. Reports indicate that nearly 40% of companies in the valve sector are investing in greener technologies. However, challenges remain. Not all companies can keep up with this shift, leading to a risk of obsolescence.

Moreover, the design of EN1074 butterfly valves is increasingly user-centric. Engineers are focusing on intuitive designs and ease of maintenance. A survey found that 60% of users prioritize simplicity in operation. This trend highlights a gap between advanced designs and practical usability. Improved training and support can help bridge this divide.

| Dimension | Description | 2026 Trend | Application Areas |

|---|---|---|---|

| Material | High-performance plastics and alloys | Increased usage of corrosion-resistant materials | Chemical processing, Water treatment |

| Size Range | From 1 inch to 48 inches | Growth in large diameter valves | Industrial pipelines, HVAC systems |

| Actuation | Manual, Electric, Pneumatic | Rising demand for automated actuation | Energy, Water management |

| Standards | Compliant with EN 1074 | Emphasis on compliance and certification | Municipal systems, Power plants |

| Technology | Smart monitoring technologies | Integration of IoT for predictive maintenance | Smart grids, Water distribution |

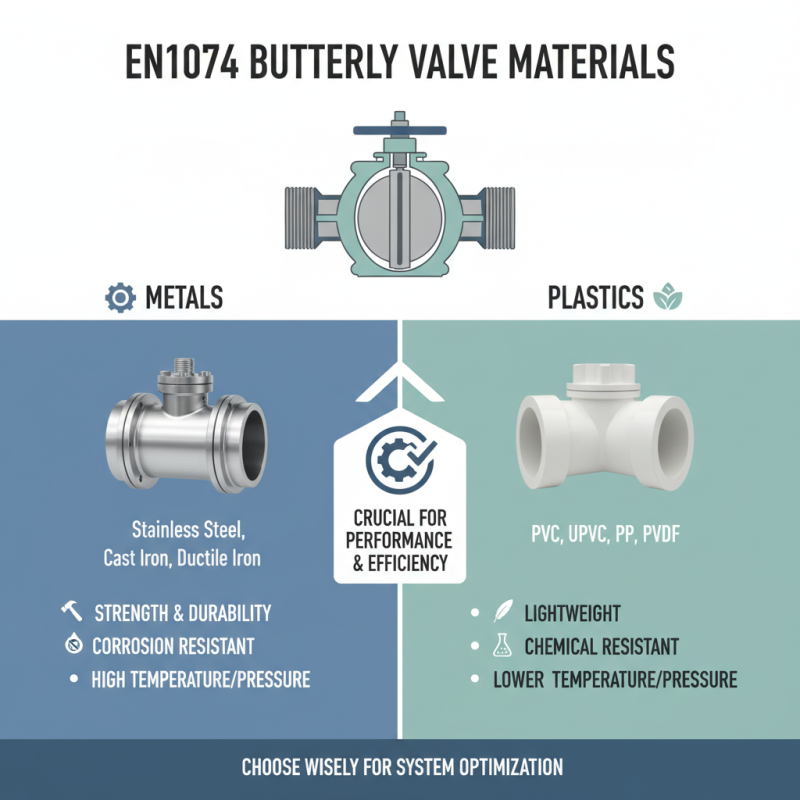

When considering the EN1074 butterfly valves in 2026, specifications and standards are vital. These valves serve essential roles in fluid control. They come with various sizes and pressure ratings. The common materials include ductile iron, stainless steel, and PVC. Each material has unique characteristics that cater to specific applications.

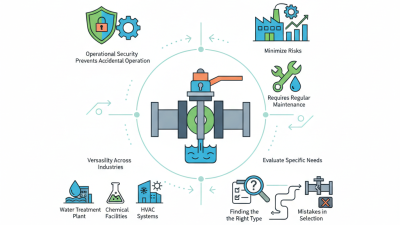

Additionally, performance standards outline operational boundaries. These include leakage rates, operating torque, and temperature ranges. Compliance with EN1074 ensures reliable functionality. However, not all manufacturers maintain these standards consistently. Some may overlook precise dimensions, leading to inefficiencies.

Maintenance is another area requiring attention. Valves must be regularly inspected and serviced. This ensures they function at peak efficiency. In busy systems, signs of wear can go unnoticed, causing leaks and downtime. User feedback is crucial here. Gathering insights from real-world performance can guide future innovations. Ultimately, staying abreast of technological advancements in butterfly valves is essential for optimal operation.

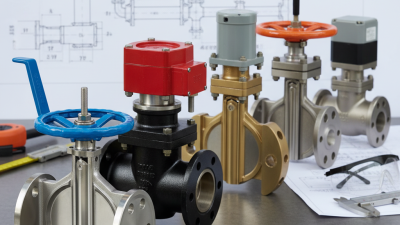

The comparative analysis of EN1074 butterfly valves against other valve types reveals significant insights. Butterfly valves feature a disc that pivots, allowing for efficient flow regulation. Their compact design makes them lighter than other valves, which is advantageous for installation and maintenance. They can be used in various applications, from water treatment to industrial systems, but their sealing capabilities may not match those of globe valves.

When investigating alternatives, gate valves provide excellent shut-off capabilities. However, they require more physical space and maintenance. Ball valves offer tight seals, ideal for on/off applications, but can be more costly. The choice between these types often hinges on specific operational requirements. Users should reflect on their unique needs, considering factors such as space, cost, and sealing performance.

While EN1074 butterfly valves are versatile, they might not be the best fit for every situation. Users could face challenges with pressure drops or flow turbulence, which could affect system efficiency. It's crucial to weigh these aspects against benefits like lower weight and ease of operation. These nuanced points often require careful deliberation to ensure the right valve is selected for peak performance.

The selection of materials is crucial in determining the performance of EN1074 butterfly valves. Different materials affect mechanical properties, corrosion resistance, and longevity. Metals like stainless steel offer strength and durability. On the other hand, plastic components reduce weight but may limit temperature and pressure ratings. Choosing the right material is not just a technical decision; it impacts the entire system's efficiency.

When considering materials, think about the environment. Corrosive liquids may require enhanced materials. A mismatched material can lead to premature failure. This is a common oversight during the design phase. Another tip: test materials under expected service conditions. This helps to avoid unexpected degradation later on.

Moreover, manufacturing processes can also influence material performance. Factors like welding, coating, or molding can introduce weaknesses. Even minor flaws can compromise integrity. A thorough review of production methods is essential. Remember, small choices can lead to significant consequences in valve performance.

The future of EN1074 butterfly valve technology is promising. Engineers are exploring new materials for durability and performance. Smart technologies are coming into play, enhancing versatility. This evolution aims to improve efficiency and reliability.

Tip: Always consider the environment when selecting materials. Some options may look good on paper but can fail under pressure.

Functionality will expand with innovative designs. Advanced automation features will streamline operations. Real-time monitoring could become standard. These systems will reduce manual input, making valves easier to manage.

Tip: Regular maintenance can reveal hidden issues. Be proactive to avoid costly repairs.

As we look ahead, challenges remain. Compatibility with existing systems is crucial. Not all innovations will fit seamlessly. It's essential to balance progress with practicality. The journey is ongoing, and reflection is necessary for continuous improvement.