Leave Your Message

As the world faces increasing water scarcity, innovations in water treatment technologies become crucial. The demand for effective solutions has never been higher, leading to the evolution of the Desalination Butterfly Valve industry. Experts like Dr. Emily Chen, a leader in this field, emphasize the importance of reliability. She famously stated, "A robust valve design ensures water safety and efficiency in desalination processes."

Recent trends highlight the push towards more efficient materials and designs in Desalination Butterfly Valves. Lightweight alloys and advanced coatings are becoming standard. These innovations meet the demands of modern desalination plants, which require durability and performance. However, challenges remain. The industry is still grappling with high operational costs and maintenance issues.

Moreover, the focus on sustainability is reshaping valve manufacturing. Companies now aim to minimize environmental impact while maximizing output. As they strive for better solutions, the path forward might not be without hurdles. These advancements remind us that growth often comes with complexities that require ongoing reflection and improvement in the Desalination Butterfly Valve sector.

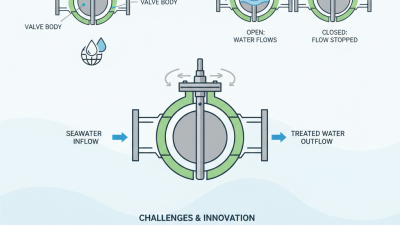

In 2026, the desalination industry is witnessing transformative innovations in butterfly valve technologies. These valves play a crucial role in the efficient operation of desalination plants. Over 40% of facilities are increasing their reliance on advanced butterfly valves. Key innovations focus on materials and automation features that enhance durability and performance.

Current reports indicate that smart valve technology is gaining traction. Data show that 30% of new installations feature smart solutions. These valves offer real-time monitoring and can significantly reduce maintenance costs. They promise to improve operational efficiency while minimizing downtime in water treatment processes.

Tips: Regular maintenance is vital. Check seals and actuation systems routinely. This practice ensures your valves operate optimally. Additionally, emerging materials like polymer composites could be game-changers. They resist corrosion and extend valve lifespan. Explore these options when upgrading existing systems.

| Parameter | Current Trends | Innovations | Impact on Efficiency |

|---|---|---|---|

| Material Selection | Increased use of corrosion-resistant materials | Advanced composite materials | Enhanced lifespan and reduced maintenance |

| Actuation Methods | Rise in electric and pneumatic actuators | Smart actuators with IoT integration | Improved control and monitoring |

| Seal Technologies | Adoption of high-performance sealing solutions | Self-regenerating seals | Reduced leak rates and enhanced reliability |

| Design Improvements | Streamlined designs for better flow | 3D printed valve components | Enhanced flow efficiency and reduced energy consumption |

| Automation and Control | Increased use of automated systems | AI-driven predictive maintenance tools | Minimized downtime and improved operational efficiency |

The 2026 trends in desalination butterfly valves are set to transform water management. Innovations are driving high-efficiency designs. These valve designs focus on reducing energy consumption. One notable advancement is the use of lightweight materials. These materials enhance durability and reduce corrosion rates. This translates to longer life cycles and lower maintenance costs.

Moreover, engineers are integrating smart technologies. Smart sensors provide real-time data on flow rates and pressure levels. This information aids in precise control and monitoring. However, the implementation of these technologies can be complex. Users may face initial setup challenges. Not all systems are user-friendly, leading to confusion in operations.

Additionally, modular designs are gaining traction. These designs allow for easy upgrades and repairs. Users can replace parts without needing to overhaul the entire system. Yet, this modular approach has its flaws. Compatibility issues may arise with older systems. Careful planning is needed to ensure smooth integration. Overall, the focus remains on enhancing efficiency in valve design for desalination.

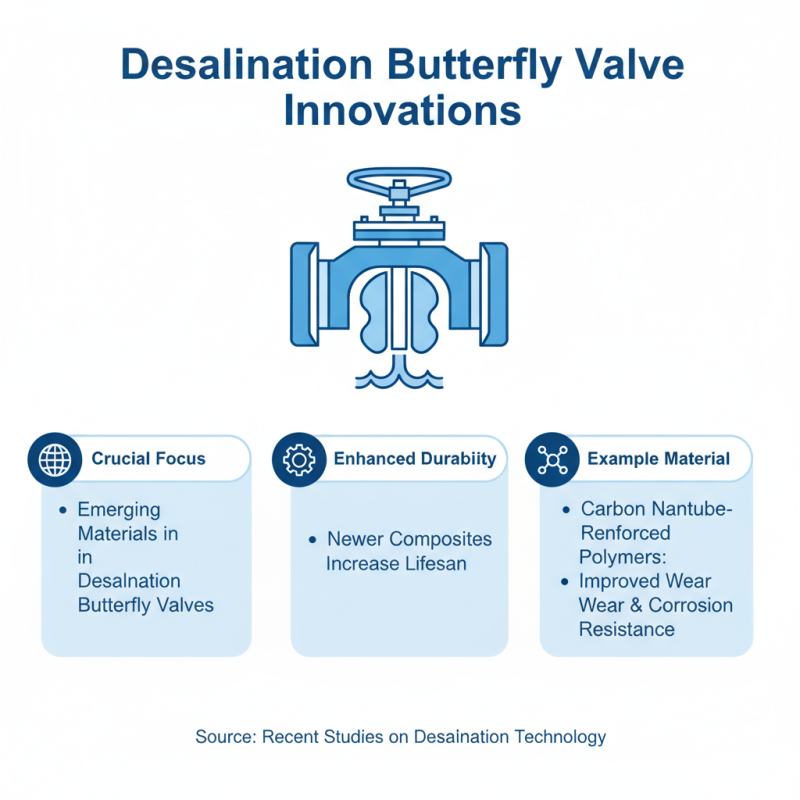

The focus on emerging materials in desalination butterfly valves is crucial. Recent studies indicate that newer composites can significantly enhance durability. For instance, polymers reinforced with carbon nanotubes show increased resistance to wear and corrosion.

One report from the Global Water Intelligence predicts that advanced materials could reduce maintenance costs by up to 30%. This is promising for the desalination industry, often burdened with high operational expenses. However, adoption challenges remain. Not all facilities can implement these materials quickly.

Durability doesn't only stem from the materials but also from the design. Butterfly valves must handle high pressures and corrosive environments. A failure in this area can lead to significant downtime. The industry needs ongoing evaluation of these innovative materials. There’s a fine line between innovation and practicality. Continuous testing is vital.

The integration of IoT in desalination processes is transforming the industry. Smart valves, for instance, can enhance efficiency and monitoring. These valves use sensors to track performance in real-time. According to a recent industry report, implementing IoT can reduce operational costs by up to 20%. This is significant for water-scarce regions relying on desalination.

Data from the International Desalination Association indicates a steady increase in desalination capacity. By 2026, global capacity is expected to exceed 100 million cubic meters per day. However, reliance on conventional systems raises concerns. Aging infrastructure can lead to inefficiencies and increased maintenance costs. Smart valves promise to address some of these issues by enabling predictive maintenance.

Despite the advancements, challenges remain. Not all systems are ready for IoT integration. Training personnel and upgrading existing infrastructure can be costly. Some operators may hesitate, fearing possible technology failures. Still, the momentum toward smart technology is undeniable. Embracing these innovations could redefine the future of desalination.

The desalination industry is evolving rapidly. One significant factor driving growth is the rising demand for freshwater. As populations expand, the pressure on water resources increases. Desalination butterfly valves play a crucial role in managing saline water efficiently.

Innovations in design are noteworthy. Engineers focus on enhancing flow control and reducing leakage. New materials improve durability and resistance to corrosion. However, some technologies still pose challenges in terms of cost and scalability. Investing in R&D is crucial, but returns can be uncertain.

Sustainability considerations also shape market dynamics. Eco-friendly practices are gaining traction. Many facilities must balance efficiency with environmental impact. Education on best practices can promote smarter choices. The path forward includes both technological progress and a commitment to responsible water management.