Leave Your Message

In the ever-evolving landscape of industrial applications, the EN593 Butterfly Valve has emerged as a critical component, offering an array of benefits that cater to diverse operational needs. According to John Smith, a renowned expert in valve technology, "The EN593 Butterfly Valve is not only a solution for effective flow control but also a testament to the advancements in engineering design that enhance operational efficiency." This statement encapsulates the essence of why industry professionals are turning to this innovative valve.

The versatility of the EN593 Butterfly Valve makes it an essential choice for various sectors, including water treatment, HVAC, and chemical processing. Its design allows for quick operation while ensuring a tight seal, significantly reducing the risk of leaks and enhancing safety. In addition to its functional advantages, the EN593 Butterfly Valve is also celebrated for its cost-effectiveness and longevity, making it a smart investment for businesses aiming to optimize their operations.

As we delve into the top ten benefits of the EN593 Butterfly Valve, it becomes clear that this component represents not just a mechanical part, but a pivotal advantage in modern industrial processes. Understanding these benefits will enable professionals to make informed decisions that align with their operational goals and enhance overall system efficiency.

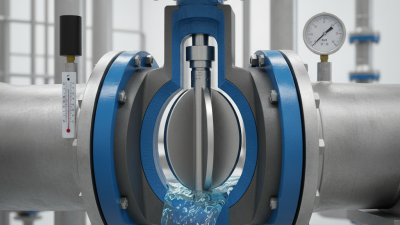

EN593 butterfly valves are essential components in fluid control systems, offering a range of benefits that enhance operational efficiency and reliability. One of the primary advantages is their ability to provide a quick and effective shut-off and control of flow. This is particularly beneficial in systems requiring precise regulation, as the design allows for reduced pressure drop and minimized turbulence. As a result, these valves support smoother operations and can lead to energy savings in pumping systems.

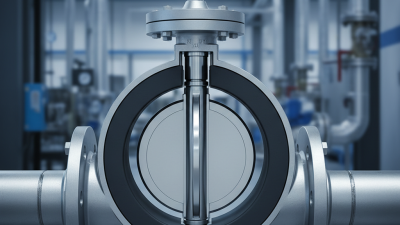

Another significant benefit of EN593 butterfly valves is their lightweight and compact design, which simplifies installation and maintenance. Their streamlined profile takes up less space compared to traditional gate or globe valves, making them ideal for applications with limited room. Furthermore, the materials used in constructing these valves provide excellent resistance to corrosion and wear, ensuring longevity and dependability in various fluid handling situations. This durability translates to lower maintenance costs over time, which is advantageous for facility operations looking to optimize their budgets while maintaining high performance.

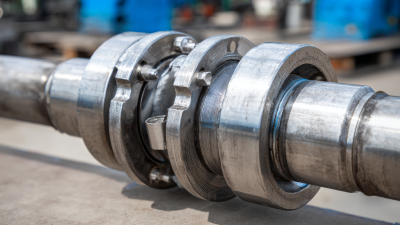

The durability and longevity of EN593 butterfly valves are critical attributes that contribute significantly to their widespread use in various industries. These valves are typically constructed from high-strength materials such as stainless steel or ductile iron, which have been shown to withstand harsh environmental conditions. According to industry reports, valves made from these materials can exhibit tensile strengths exceeding 400 MPa, ensuring that they can handle the pressures and stresses typically encountered in service. Furthermore, comparative studies indicate that butterfly valves designed to meet EN593 standards have a significantly lower failure rate, with a reported lifespan of over 20 years under optimal conditions, showcasing their reliability.

Performance metrics also highlight the efficiency of EN593 butterfly valves in flow control applications. A study conducted by a leading valve industry organization found that these valves can achieve a tight shut-off capability of up to 0.01% leakage, demonstrating their effectiveness in preventing fluid loss. The design features of the EN593 butterfly valves, including their streamlined disk shapes and resilient sealing materials, contribute to reduced pressure drops, enhancing system performance. Furthermore, with their ability to operate in a wide temperature range—from -10°C to 100°C—these valves remain functional in diverse operating environments, making them an excellent choice for industries such as water treatment, oil and gas, and HVAC systems.

The following chart illustrates the top benefits of EN593 Butterfly Valves based on material strength and performance metrics. Each benefit is rated on a scale from 1 to 10, reflecting its significance in terms of durability and longevity.

The EN593 butterfly valves are renowned for their energy efficiency, particularly in flow control applications. Their design allows for effective modulation of fluid flow while minimizing energy loss. According to a report by the American Society of Mechanical Engineers (ASME), using appropriately sized butterfly valves can reduce pressure drop by up to 30%. This reduction not only enhances system performance but also leads to substantial energy savings in long-term operation, which is critical in industries where energy costs represent a significant portion of operational expenses.

A detailed analysis of flow control data reveals that EN593 butterfly valves maintain a stable flow rate across various pressure conditions. This stability is essential in applications requiring precise flow measurements. The Hydraulic Institute reports that valves that optimize flow control can lead to efficiency gains of approximately 15-20%. The ability of EN593 butterfly valves to regulate flow with minimal turbulence further contributes to energy conservation, as the streamlined flow path lessens the energy required to pump fluids through piping systems. Overall, these benefits underline the role of EN593 butterfly valves in advancing energy-efficient practices across various industrial applications.

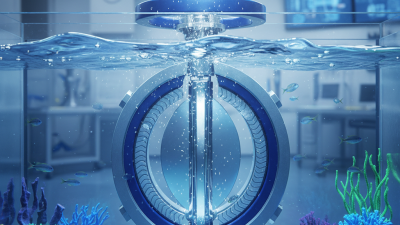

EN593 butterfly valves are widely recognized for their adaptability across various industries, making them a popular choice in many applications. These valves are primarily used in water supply systems, where they facilitate the control of water flow with minimal pressure loss. Their lightweight design allows for easy installation and maintenance, which is crucial in municipal utilities that require reliable yet efficient solutions. Additionally, EN593 butterfly valves are frequently utilized in wastewater treatment plants, as they can handle harsh environmental conditions and effectively manage the flow of sewage and industrial effluents.

The versatility of EN593 butterfly valves extends beyond utility sectors; they are also essential in chemical processing industries. Their ability to withstand corrosive substances makes them ideal for controlling the flow of chemicals in various manufacturing processes. Furthermore, the food and beverage industry employs these valves to manage the flow of products while ensuring strict hygiene standards. With the capability to operate in high temperatures and pressures, EN593 butterfly valves are thus indispensable in industries where reliability and safety are paramount. Whether in industrial applications or in commercial systems, the diversity of uses for EN593 butterfly valves underscores their significance in modern engineering solutions.

The EN593 butterfly valve is known for its impressive cost-effectiveness, particularly when it comes to long-term use and maintenance savings. One of the primary advantages is its design, which allows for efficient flow control and reduces energy consumption in systems that use these valves. This efficiency translates into lower operational costs, enabling organizations to realize significant returns on their investments over time. As the need for energy-efficient solutions grows, the EN593 butterfly valve emerges as an ideal choice for those looking to optimize their expenditure.

Furthermore, maintenance of EN593 butterfly valves is generally straightforward, contributing to additional savings. Due to their simple yet robust construction, these valves require less frequent repairs compared to more complex systems. This reliability minimizes downtime and the associated costs of loss in production or service. Additionally, the materials used in their construction often resist corrosion and wear, extending the service life of the valves. Over time, the combination of lower maintenance needs and longer life expectancy makes the EN593 butterfly valve a financially savvy selection for many industrial applications.