Leave Your Message

In the realm of marine applications, the significance of using Sea Water Butterfly Valves cannot be overstated. These specialized valves are designed to handle the unique challenges posed by seawater environments, including corrosive effects and fluctuating pressures. According to Dr. James L. Fisher, a renowned expert in marine engineering, "The right valve can make all the difference in maintaining system efficiency and reliability in harsh seawater conditions." His insight underscores the critical role that Sea Water Butterfly Valves play in ensuring the longevity and effectiveness of marine systems.

The adoption of Sea Water Butterfly Valves offers a multitude of benefits, ranging from enhanced flow control to reduced maintenance costs. Their lightweight design and simple operation make them an ideal choice for a variety of marine applications, including shipbuilding, coastal infrastructure, and offshore platforms. As the global marine industry continues to evolve, the need for robust and reliable components becomes ever more vital. In this context, understanding the advantages of Sea Water Butterfly Valves can empower engineers and project managers to make informed decisions that promote operational efficiency and sustainability.

In summary, the exploration of the top 10 benefits of using Sea Water Butterfly Valves reveals not only their critical functionality but also their role in advancing marine technology. As the industry faces increasing demands from both environmental regulations and performance standards, incorporating these valves can be a strategic move towards achieving superior results in marine applications.

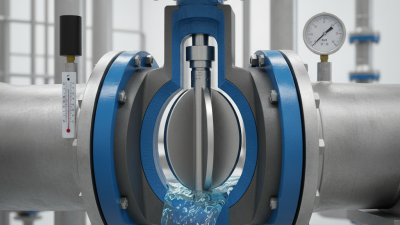

Sea water butterfly valves are critical components in marine applications, providing efficient flow control and durability in harsh environments. Designed specifically for marine systems, these valves utilize a disc that rotates around a central axis, allowing for precise regulation of seawater flow. Their construction often includes materials like corrosion-resistant alloys or special coatings, which enhance their longevity in saline conditions. According to industry reports, proper selection and installation of butterfly valves can increase system efficiency by up to 25%, minimizing the risk of failures in marine setups.

When considering the functionality of sea water butterfly valves, understanding their operational mechanics is essential. These valves can be operated manually or automatically, offering flexibility depending on the application requirements. They are typically employed in cooling water systems, ballast systems, and waste discharge systems on vessels. Enhanced sealing capabilities prevent leaks, which is crucial for maintaining the environmental integrity of marine operations. Additionally, studies show that the standard maintenance intervals for these valves can help extend their lifespan significantly, often exceeding 20 years with proper care.

Tips: Always ensure that the materials selected for sea water butterfly valves are compatible with the specific salinity and temperature ranges of your marine environment. Regular inspections and maintenance routines can help detect potential issues before they escalate, ensuring the system operates smoothly. Planning for replacements during scheduled downtimes can minimize disruptions and maintain operational efficiency.

| Benefit | Description | Application Examples |

|---|---|---|

| Corrosion Resistance | Designed to withstand harsh marine environments without degradation. | Shipboard systems, offshore platforms. |

| Reduced Weight | Lighter than traditional valve materials, improving overall vessel efficiency. | Yacht plumbing systems, commercial fishing vessels. |

| Easy Operation | Simple mechanism allows for swift opening and closing even under high pressure. | Ballast tanks, seawater intakes. |

| Low Maintenance | Long service life with minimal upkeep required, reducing operational costs. | Industrial marine systems, aquaculture. |

| Versatile Applications | Can be used in various marine environments and systems. | Desalination plants, wastewater treatment. |

| Cost-Effective | Offers long-term savings through durability and efficiency. | Marine cargo handling, fisheries. |

| Improved Flow Control | Allows for precise adjustments in water flow and pressure. | Cooling systems on ships, fire suppression systems. |

| Environmental Compliance | Manufactured to meet strict marine environmental regulations. | Ports, coastal facilities. |

| Wide Range of Sizes | Available in various dimensions to fit diverse marine applications. | Power plants, dockside utilities. |

Sea water butterfly valves play a crucial role in marine applications, offering distinct advantages tailored to the unique challenges faced in aquatic environments. One of the primary benefits lies in their corrosion resistance. According to a report by the International Maritime Organization, marine equipment—including valves—faces severe corrosion due to saltwater exposure, which can decrease lifespan and performance. Sea water butterfly valves typically utilize materials such as stainless steel or specialized coatings that significantly extend durability, making them a reliable choice for vessels operating in harsh marine conditions.

Another key advantage of sea water butterfly valves is their lightweight design, which greatly contributes to energy efficiency in marine applications. Research from the Marine Engineering Journal indicates that every 10% reduction in weight on a ship can lead to a 5% improvement in fuel efficiency. With lighter valve options available, operators can enhance overall vessel performance while minimizing fuel costs. Additionally, the ease of maintenance associated with butterfly valves enables quick and efficient repairs or replacements, further reducing downtime and operational costs. This combination of durability, efficiency, and low maintenance makes sea water butterfly valves an essential component for marine environments.

The marine environment presents unique challenges when it comes to equipment durability, particularly regarding corrosion. Sea water butterfly valves are designed specifically for these harsh conditions. Their construction often employs materials that can withstand the corrosive effects of seawater, making them a reliable choice for marine applications. The ability to resist corrosion not only extends the lifespan of these valves but also reduces maintenance costs over time, a significant advantage for marine operators.

Tips for selecting the right sea water butterfly valve include considering the valve material carefully. Stainless steel and specialized alloys are preferred for their superior resistance to rust and corrosion. Additionally, evaluating the valve's design and installation can further enhance its performance in marine applications. Regular inspections and maintenance can also help to identify potential issues before they become significant, ensuring the reliability of the valve in corrosive environments.

Maintaining a proper sealing mechanism is another critical aspect. Ensure that the valve provides tight sealing to prevent leaks and reduce pressure loss. Choosing valves with other anti-corrosion features, such as coatings or linings, can provide extra defense against the harsh marine elements, further enhancing the overall efficiency and security of marine operations.

Maintenance and longevity are crucial factors when considering the performance of sea water butterfly valves in marine applications. These valves are specifically designed to withstand the corrosive nature of seawater, which can significantly impact their operational life if not properly maintained. Regular inspection and maintenance protocols should include checking for signs of wear or corrosion, ensuring that seals and gaskets are intact, and verifying that the valve's actuating mechanism is functioning smoothly. Implementing these practices helps extend the lifespan of the valves and ensures reliable performance in demanding marine environments.

In addition to proactive maintenance measures, selecting the appropriate materials for the construction of sea water butterfly valves plays a vital role in their longevity. Utilizing robust materials that resist saltwater corrosion is essential, as it directly influences the frequency and extent of maintenance required. Furthermore, employing protective coatings can enhance the durability of these valves, reducing the effects of biofouling and erosion typically encountered in marine settings. By emphasizing quality materials and regular servicing, operators can ensure that sea water butterfly valves perform efficiently over extended periods, thereby optimizing operational reliability and reducing overall lifecycle costs.

When considering marine applications, the cost-effectiveness of using sea water butterfly valves becomes a significant advantage. These valves are specifically designed to withstand the harsh conditions of saltwater environments, thereby reducing maintenance needs and extending their lifespan. This durability minimizes the costs associated with replacements and repairs, making them a financially sound choice for marine operations. The initial investment in sea water butterfly valves pays off through long-term savings, as operators can avoid frequent service interruptions and the associated downtime.

Additionally, the installation of sea water butterfly valves can lead to improved operational efficiency, further enhancing their cost-effectiveness. By facilitating smooth flow control and reducing pressure drops, these valves contribute to lower energy consumption within marine systems. When systems operate efficiently, the overall operational costs decrease, leading to notable savings over time. Moreover, their lightweight design makes them easier to install and handle, thereby lowering labor costs during installation, which ultimately reflects positively on the budget of marine projects.