Leave Your Message

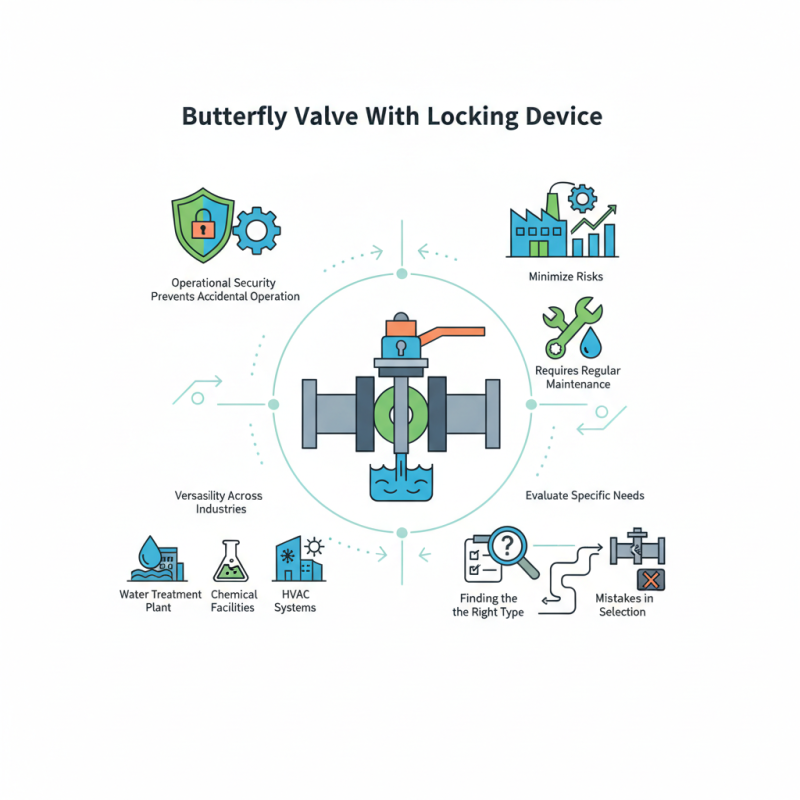

In industrial applications, the "Butterfly Valve With Locking Device" stands out for its unique benefits. Experts like Dr. Emily Carter, a renowned valve specialist, emphasize its importance in maintaining safety. She once stated, "Incorporating a locking device in a butterfly valve significantly enhances operational security."

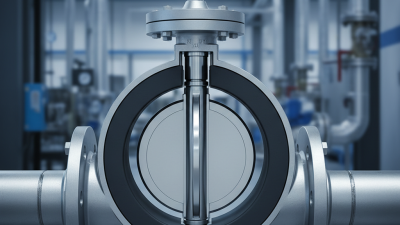

The design of a butterfly valve provides swift flow control. The addition of a locking device prevents accidental operation, which is crucial in critical environments. Facilities can minimize risks by ensuring valves remain securely in place. However, it’s essential to remember that not all locking mechanisms are foolproof. Some may require regular maintenance to ensure effectiveness.

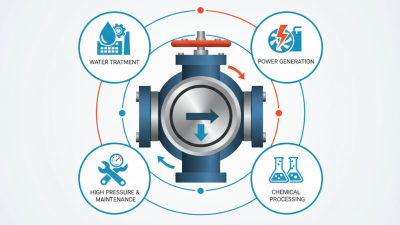

Locking devices in butterfly valves offer versatility across industries. They can be used in water treatment plants, chemical facilities, and HVAC systems. Still, users must evaluate specific needs carefully. Finding the right type can be challenging. Mistakes in selection might lead to unsafe situations or inefficient operations. Consider your application thoroughly before making a choice.

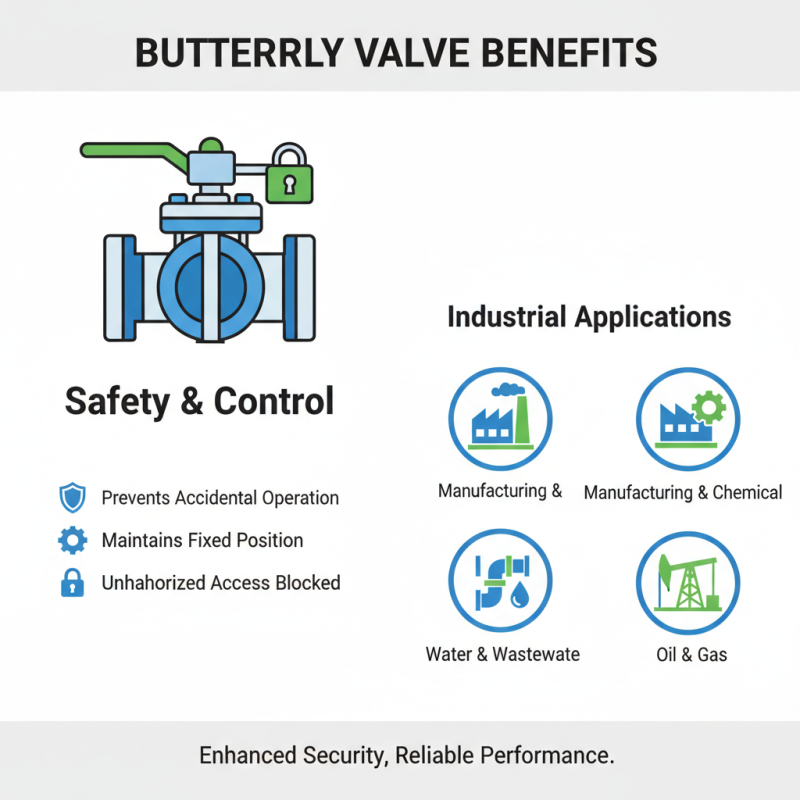

Butterfly valves equipped with locking devices offer numerous benefits for various applications. One key feature is their ability to prevent accidental operation. This is especially useful in industrial settings where safety is paramount. The locking mechanism ensures that the valve remains in a fixed position, preventing unauthorized access or operation.

Another notable feature is ease of use. Many butterfly valves are designed for quick opening and closing. The locking device complements this by allowing operators to secure the valve in the desired position. This combination promotes operational efficiency and reduces the risk of mishandling. However, not all users appreciate the complexity of some locking mechanisms, which can be a point of frustration.

Maintenance is another important consideration. While butterfly valves are typically robust, the locking device may require periodic checks. Users might overlook this, leading to operational issues. Additionally, the key for the locking mechanism can be misplaced easily. Despite these potential drawbacks, the benefits generally outweigh them. A well-functioning butterfly valve with a locking device significantly enhances safety and control in various environments.

Locking mechanisms in butterfly valves provide enhanced security and operational control. These devices ensure that the valve remains in a fixed position. This is crucial in applications where leakage or accidental opening could occur. A locked valve can withstand pressure variations better. This is particularly important in water treatment or industrial processes.

The use of locking devices also improves safety for operators. If a valve is inadvertently opened, this could lead to catastrophic failures. With a locking mechanism, operators can proceed with tasks without the constant concern of unintentional valve movements. However, there are scenarios where locks may complicate operations. If maintenance is needed, it can become a hassle to unlock.

Moreover, the need for regular checks on these mechanisms arises. If neglected, they may fail to engage properly. Understanding how and when to use these locks is essential for effective operations. Some might overlook the simple act of checking the lock. Regular reflections on their function could prevent costly mistakes.

Locking butterfly valves are crucial in many industries. They provide not just flow control but also enhanced safety. In applications that require secure operation, these valves prevent unauthorized access. According to a recent industry report, the demand for locking butterfly valves is anticipated to grow by 5% annually over the next five years. This growth is driven by their versatility and reliability in harsh environments.

Common applications for locking butterfly valves span various sectors. They are widely used in water treatment facilities to manage flow efficiently. In chemical processing plants, these valves ensure that dangerous substances are kept contained. A study indicated that improper valve management can lead to hazardous leaks, highlighting the necessity of secure options. Additionally, in the oil and gas industry, these valves help maintain security throughout pipelines. Even small oversights in valve operation can result in significant financial losses.

Locking features are particularly important in municipal water systems. The control they provide can prevent misuse and protect public resources. However, many systems still rely on standard valves without locking mechanisms. This gap poses risks that could be easily mitigated. It's essential for operators to evaluate the safety measures of their equipment regularly. A proactive approach can help prevent accidents and enhance system integrity.

When installing butterfly valves with locking devices, proper guidance is crucial. Choose a suitable location for the valve. Consider ease of access for operation and maintenance. Ensure there is enough clearance around the valve. This facilitates the installation process. Correct orientation is vital; follow the flow direction marked on the valve.

Before installation, double-check all components. Inspect the valve for any damage or defects. A damaged valve compromises performance. Ensure that the sealing surfaces are clean. Dirty surfaces can lead to leaks after installation.

Once the valve is secured, test the locking device. The purpose of the locking feature is to enhance safety. During the initial operation, monitor the valve’s performance. Look for any unusual noises or movements. Adjustments may be necessary after the first use. Regularly inspect the locking mechanism for wear. Ensuring its reliability is key to preventing issues.

| Feature | Description | Benefits | Common Uses |

|---|---|---|---|

| Locking Device | A mechanism that prevents unauthorized operation of the valve. | Enhances safety by preventing accidental opening or closing. | Water systems, chemical processing, HVAC systems. |

| Material Types | Available in various materials like stainless steel, PVC, and cast iron. | Corrosion resistance and adaptability to different fluids. | Oil and gas, mining, water treatment. |

| Operational Control | Manual or automated operation options. | Flexibility in control based on system requirements. | Industrial applications, process management. |

| Maintenance | Requires periodic inspection and maintenance for optimal performance. | Prolongs life of the valve and ensures reliability. | Pipelines, fire protection systems. |

| Installation Guidelines | Follow manufacturer specifications, ensure proper alignment. | Prevents leaks and operational issues. | Municipal water supply, irrigation systems. |

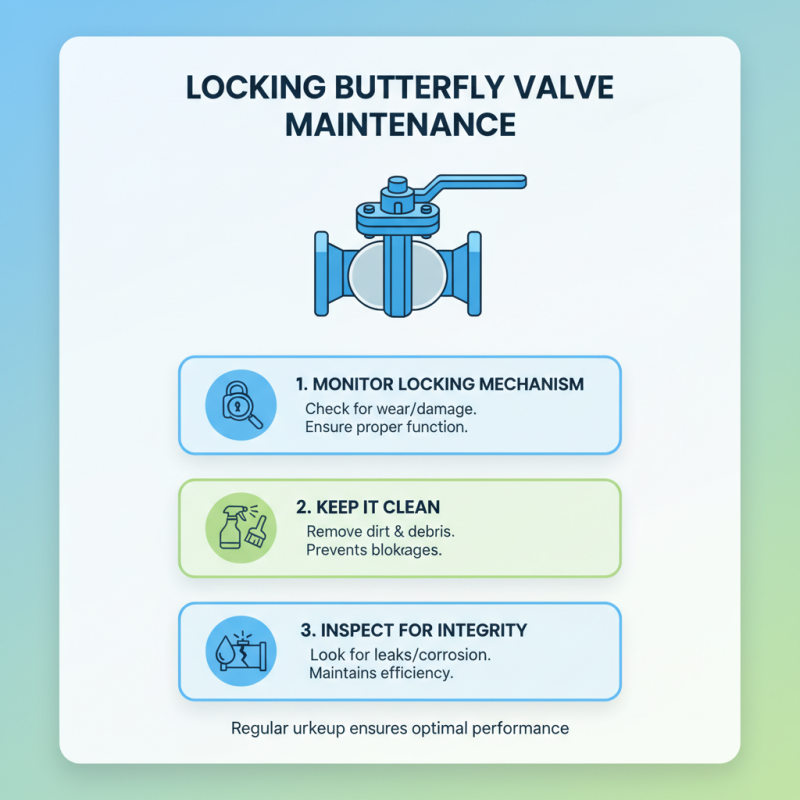

Locking butterfly valves require regular maintenance for optimal performance. Monitoring the locking mechanism is crucial. Check for any signs of wear or damage on the locking device. A malfunctioning lock can compromise the valve’s efficiency. It’s important to keep the valve clean and free of debris. Regularly inspect the valve body for any leaks or corrosion.

Greasing the moving parts can enhance the valve's operation. Use appropriate lubes to avoid attracting dirt. Tightening bolts and checking seals will prevent failures. Remember, even small leaks or loose fittings can lead to significant issues. Proper analysis of performance is key.

Record and analyze your findings over time. This reflection helps identify patterns. If a locking valve doesn’t respond well, it may need further evaluation. Being aware of usability will help in making timely repairs. Regular maintenance leads to longer lifespan and better functionality.