Leave Your Message

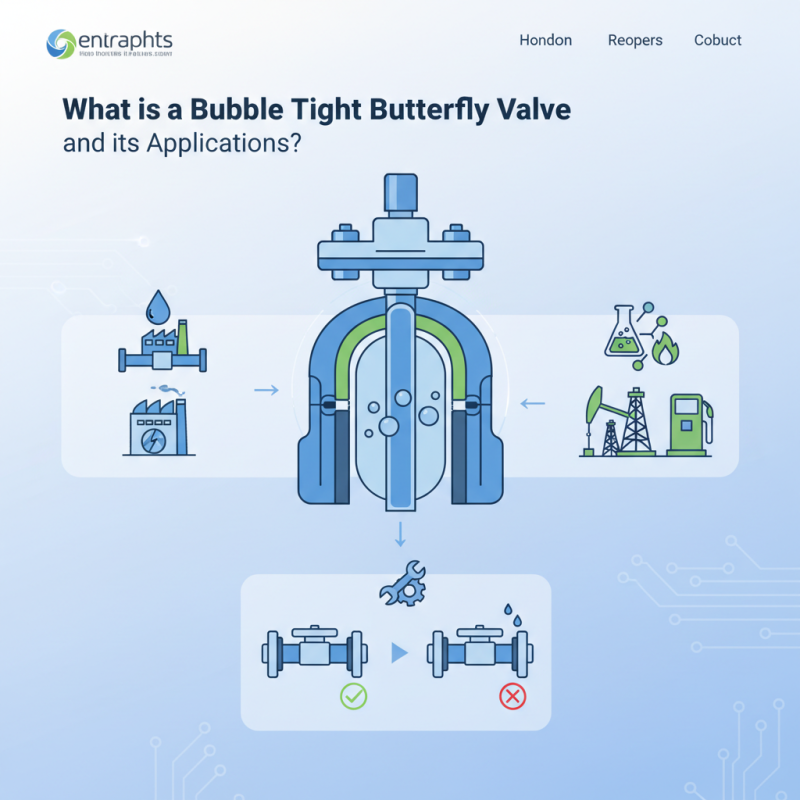

The Bubble Tight Butterfly Valve is a critical component in modern fluid control systems. Designed to minimize leakage, this valve ensures processes remain efficient and safe. Its unique design features a resilient sealing mechanism, allowing it to maintain a bubble-tight seal. This means that the fluid contained within a system remains precisely where it should be.

These valves have various applications across different industries. For example, they are widely used in water treatment plants, chemical processing, and oil and gas sectors. The valve's ability to manage high pressure and temperature makes it suitable for many environments. However, not all usages are without issues. Installation errors or improper maintenance can lead to suboptimal performance.

In some cases, a Bubble Tight Butterfly Valve may fail to provide a complete seal. This can result in environmental concerns or financial loss. Therefore, understanding the nuances of this valve type is essential for achieving desired outcomes. Users must reflect on these possibilities to ensure optimal functionality.

Bubble tight butterfly valves are a crucial component in various industries. These valves are designed to provide a leak-proof seal when closed, making them ideal for applications requiring absolute containment. In sectors such as water treatment, oil and gas, and chemical processing, the need for reliability is paramount. A recent industry report highlighted that bubble tight performance can reduce leakage rates to less than 0.01%, emphasizing their effectiveness.

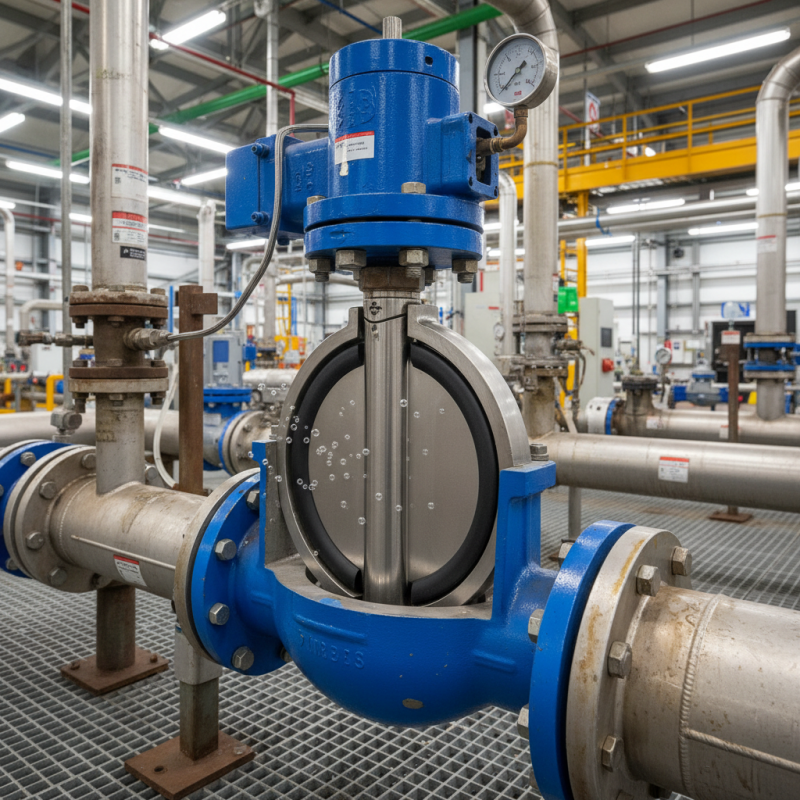

The construction of these valves typically includes a resilient seat and a disc that rotates 90 degrees for operation. This design allows for quick shut-off and minimal pressure drop when the valve is open. In practical applications, this means less energy consumption and reduced operational costs. However, improper installation can lead to performance issues. Even with advanced engineering, factors like wear and material degradation can compromise the valve's seal over time.

Maintaining these valves is critical. Regular checks and replacements are necessary to ensure they continue to perform their intended function. According to industry standards, about 15% of failures in valve systems can be attributed to inadequate maintenance. While bubble tight butterfly valves are highly effective, organizations must remain vigilant. Effective management practices help mitigate the risks associated with valve failure in critical processes.

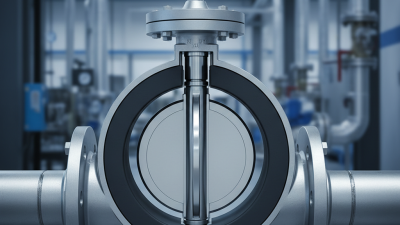

Bubble tight butterfly valves are designed for maximum sealing efficiency. Their construction includes a unique disc that prevents any leakage when closed. This feature is critical in many industries where fluid containment is vital. Typically made of robust materials, these valves can withstand high pressure and temperature. The use of rubber or Teflon seals enhances their sealing capability, contributing to their bubble-tight function.

In terms of design, these valves have a simple structure. This simplicity allows for easy operation and maintenance. The actuator is often manual or automated, making it versatile for various applications. It’s worth noting that while these valves excel in preventing leaks, challenges can arise in very high-pressure scenarios. Understanding the specific requirements of a system is essential. Proper alignment during installation is also crucial to avoid leaks. A small oversight can lead to significant issues down the line. Thus, attention to detail in both design and implementation is key.

Bubble tight butterfly valves are critical in many industrial applications. They prevent leakage with a reliable sealing mechanism. This feature is especially key in industries dealing with fluids or gases. The design minimizes pressure drops while controlling flow effectively. Users often choose these valves for their efficiency in handling various media.

One notable advantage is their simple construction. Fewer moving parts mean lower maintenance needs. However, this can lead to oversight in inspections. Some operators may not check valves regularly, risking failure when it’s most needed. Additionally, the compact size allows for installation in tight spaces, but this compactness sometimes impedes easy access for repairs.

In environments where absolute tightness is crucial, bubble tight butterfly valves excel. They are widely used in water treatment, chemical processing, and power generation. Yet, maintenance practices can vary significantly across facilities. Proper training on these valves is imperative for ensuring longevity and performance. Regular audits should not be overlooked, as they help identify potential issues early.

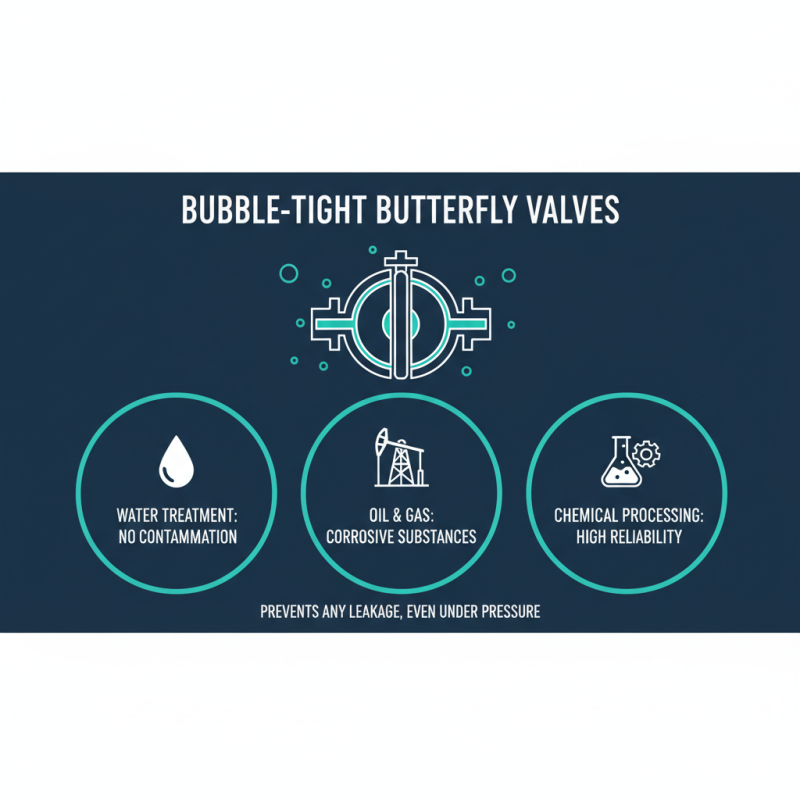

Bubble tight butterfly valves are essential in various industries. They are designed to prevent any leakage, even under pressure. This feature makes them ideal for applications requiring high reliability. Common uses include water treatment, oil and gas, and chemical processing. In water treatment, these valves ensure no contamination occurs. In oil and gas, they handle corrosive substances effectively.

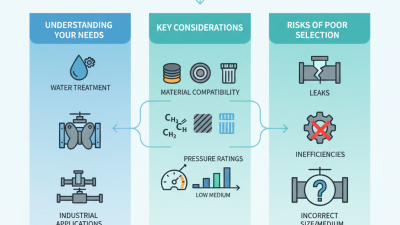

Tip: When selecting a bubble tight butterfly valve, consider the medium it will be used for. Ensure compatibility to avoid issues later.

In chemical processing, these valves offer excellent flow control. They help in maintaining precise conditions for reactions. Additionally, they are often lighter and more compact compared to other valve types. This can save space in installations. However, installation can be tricky if not done properly.

Tip: Regular maintenance is crucial. It helps in ensuring the longevity of butterfly valves. Check for wear and tear periodically. This will save costs in the long run.

Bubble tight butterfly valves are essential in various industries. Regular maintenance is critical. According to a report from the Flow Control Institute, improper maintenance can reduce the lifespan of these valves by up to 30%. Operators must inspect seals regularly to prevent leaks. They should check for wear and tear, which can compromise performance.

Troubleshooting involves several simple steps. Start with visual inspections. Look for corrosion or unusual wear. Use appropriate tools to perform routine checks. If the valve fails to close tightly, examine the actuator and linkage for issues. Leaks can also indicate seal problems. Industry standards suggest that 85% of valve failures occur due to neglect.

Educating operators on proper maintenance is vital. Regular training can help improve awareness about potential issues. Inadequate knowledge can lead to costly downtime. The goal is to ensure bubble tightness during operations. This requires a proactive approach to maintenance and troubleshooting.

| Dimension | Standard Values | Applications | Maintenance Tips | Troubleshooting |

|---|---|---|---|---|

| Size (inches) | 2" - 24" | Water Treatment, HVAC | Regular inspection and cleaning | Check for seal wear and misalignment |

| Pressure Rating | 150 psi - 300 psi | Oil & Gas, Chemical Processing | Lubricate stem regularly | Inspect valve operation under load |

| Temperature Range | -20°F to 300°F | Food & Beverage, Pharmaceutical | Ensure proper tightening of fasteners | Look for leaks around the seat |

| Body Material | Stainless Steel, PVC | Mining, Power Generation | Perform visual inspections regularly | Check actuator function periodically |