Leave Your Message

In industrial applications, the efficiency and reliability of fluid control systems are paramount, which is why the use of Butterfly Valve With Bypass has garnered significant attention in recent years. According to a report by Technavio, the global butterfly valve market is expected to grow by approximately 3% annually, reflecting an increasing demand for innovative solutions in fluid regulation, especially in sectors such as oil and gas, water treatment, and power generation. The inclusion of a bypass feature in butterfly valves is particularly advantageous, as it facilitates smoother operation and enhanced control over flow rates while minimizing the potential for pressure drops within the system.

The Butterfly Valve With Bypass not only allows for effective isolation and throttling of flow but also enables maintenance operations without the need for complete system shutdown. This dual capability is supported by findings from the International Society of Automation, which indicate that systems employing valves with bypass mechanisms can reduce downtime by up to 40%, thereby significantly increasing productivity. As industries continue to focus on optimizing their processes and maximizing uptime, understanding the applications and benefits of Butterfly Valve With Bypass becomes crucial for engineers and decision-makers alike. This insightful exploration reveals how these valves serve as a cornerstone in achieving operational excellence and reliability in fluid management across multiple sectors.

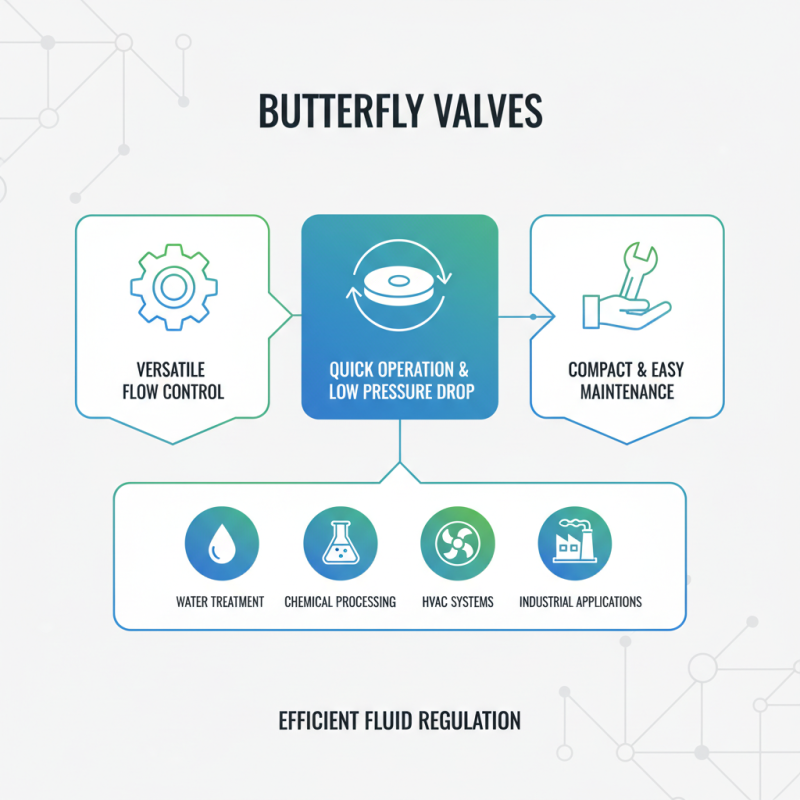

Butterfly valves are versatile and efficient devices used to control the flow of fluids in various applications. They consist of a rotating disc mounted on a shaft, which pivots to open or close the valve. This simple design allows for quick operation and minimal pressure drop, making butterfly valves ideal for use in different industries, including water treatment, chemical processing, and HVAC systems. Their lightweight structure and compact design enable easier installation and maintenance compared to traditional valve types.

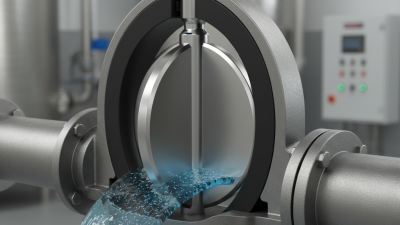

The functionality of a butterfly valve is primarily based on its ability to regulate flow with minimal resistance. When the valve is fully open, the disc is parallel to the flow direction, allowing for unobstructed fluid movement. Conversely, turning the shaft 90 degrees rotates the disc into the flow, effectively blocking it. Some butterfly valves also come with a bypass feature, allowing a small volume of fluid to flow even when the valve is mostly closed. This can be particularly useful in applications where maintaining a specific flow rate is critical, or for keeping pressure systems stable during maintenance or operational adjustments. Overall, the butterfly valve's simplistic yet effective design contributes to its widespread use across various sectors.

Butterfly valves with bypass systems are increasingly recognized for their versatility and efficiency in various industrial applications. One of the primary applications is in water treatment plants, where maintaining optimal flow rates is crucial. According to a report by the World Health Organization, inefficient water distribution systems can lead to a 40% loss in flow efficiency. Incorporating bypass systems into butterfly valves allows for better flow management, providing a regulated route that ensures continuous operation during maintenance or valve isolation. This capability is essential for reducing downtime and enhancing overall system reliability.

Another significant application is in HVAC systems, where controlling airflow is vital for energy efficiency and comfort. A study by the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE) indicates that approximately 30% of energy consumption in buildings is attributed to heating and cooling. Butterfly valves equipped with bypass systems contribute to energy savings by allowing precise flow adjustments without full shut-off, thus optimizing system performance. Furthermore, the ability to divert flow reduces the load on pumps and compressors, extending their lifespan and minimizing maintenance costs. The integration of bypass systems in butterfly valves, therefore, supports sustainable practices while improving operational efficacy across various sectors.

| Application Area | Bypass Valve Type | Key Benefits | Typical Media |

|---|---|---|---|

| Water Treatment | Lug Type | Space-saving design, corrosion resistance | Water, Chemicals |

| HVAC Systems | Wafer Type | Quick operation, low pressure drop | Air, Refrigerants |

| Chemical Processing | High Performance | Durability, ability to handle high pressure | Acids, Solvents |

| Food & Beverage | Sanitary Type | Easy cleaning, smooth flow | Water, Juices, Syrups |

| Oil & Gas | Metal Seated | High temperature resistance, reliable sealing | Crude Oil, Natural Gas |

Integrating bypass features in butterfly valves offers several significant benefits, particularly in applications where flow control and system efficiency are paramount. One of the primary advantages of incorporating a bypass is that it allows for smoother operation during valve closure and opening. This is crucial in systems requiring precise control, as the bypass can help maintain a steady flow, reducing the risk of pressure surges and water hammering that can damage equipment and compromise system integrity.

Additionally, a bypass mechanism enhances maintenance efficiency. Since it enables flow bypass during valve servicing, the system doesn't have to be entirely shut down, resulting in minimal disruption. This feature is essential for industries where continuous operation is critical, such as in chemical processing or water treatment. By permitting maintenance activities without halting the overall system, operators can ensure a reliable and consistent supply while simultaneously addressing any operational issues swiftly.

Moreover, integrating bypass capabilities can improve energy efficiency. By optimizing flow and reducing unnecessary backpressure, systems can operate more effectively, leading to lower energy consumption and cost savings in the long term. Such advantages make the incorporation of bypass features in butterfly valves a valuable consideration for engineers and system designers aiming for enhanced performance and reliability.

When comparing butterfly valves to traditional valve types, several key differences become apparent that highlight the unique advantages of butterfly valves. Butterfly valves are designed with a single disc that rotates around a central axis, allowing for quick opening and closing. This design not only reduces the amount of space required for installation but also facilitates easy and efficient operation. Traditional valves, such as gate and globe valves, often feature more complex designs that can be bulkier and slower to operate. This can make butterfly valves a preferable choice in applications where space is limited and quick response times are essential.

Another significant aspect of butterfly valves is their flow regulation capabilities. They offer excellent control over flow rates, which is particularly beneficial in processes requiring consistent flow management. Traditional valves may excel in fully open or fully closed applications but often lack the precise control offered by butterfly valves. Additionally, the streamlined design of butterfly valves minimizes pressure drop across the valve, enhancing system efficiency. This attribute becomes increasingly important in large-scale systems where energy savings can lead to substantial operational cost reductions. The comparative analysis reveals that in many scenarios, butterfly valves provide advantageous features, making them a preferred option in modern fluid control applications.

Maintenance is a critical aspect of ensuring the reliability and longevity of butterfly valves with bypass options. Regular inspection and servicing can help identify potential issues before they escalate. Key maintenance tasks include checking the actuator, inspecting the valve body for signs of wear or corrosion, and ensuring that the bypass mechanism is functioning correctly. Any buildup of debris or deposits can hinder performance, so periodic cleaning is essential. Operators should also verify the tightness of all connections and seals to prevent any leaks that could compromise the system.

In addition to routine checks, it is important to adhere to the manufacturer's guidelines for maintenance intervals and procedures. Operators should document all maintenance activities, including the replacement of parts like gaskets and seals, to ensure compliance with operational standards. Lubrication of moving parts also plays a vital role in maintaining smooth operation and reducing wear over time. By prioritizing these maintenance considerations, facilities can enhance the performance of butterfly valves with bypass options, leading to improved efficiency and reduced operational costs.