Leave Your Message

In the world of industrial flow control, the "Butterfly Valve With Bypass" plays a vital role. This valve type offers unique advantages, including space efficiency and straightforward design. According to a recent report by the Global Valves Market Research, the butterfly valve market is projected to reach $10 billion by 2025, indicating strong demand.

The Butterfly Valve With Bypass allows for better flow regulation in systems where pressure fluctuations can occur. This feature helps maintain stable operations, especially in water treatment and chemical processing facilities. However, not all installations utilize this valve type effectively. Some operators may overlook its potential for error reduction and efficiency improvement.

While many manufacturers promote these valves' benefits, users should consider the specifics of their applications. Issues like incorrect sizing or improper installation can negate the advantages. Refining the understanding of how this valve works is crucial for optimal performance. Therefore, examining its functionality and best practices is essential for achieving desired outcomes.

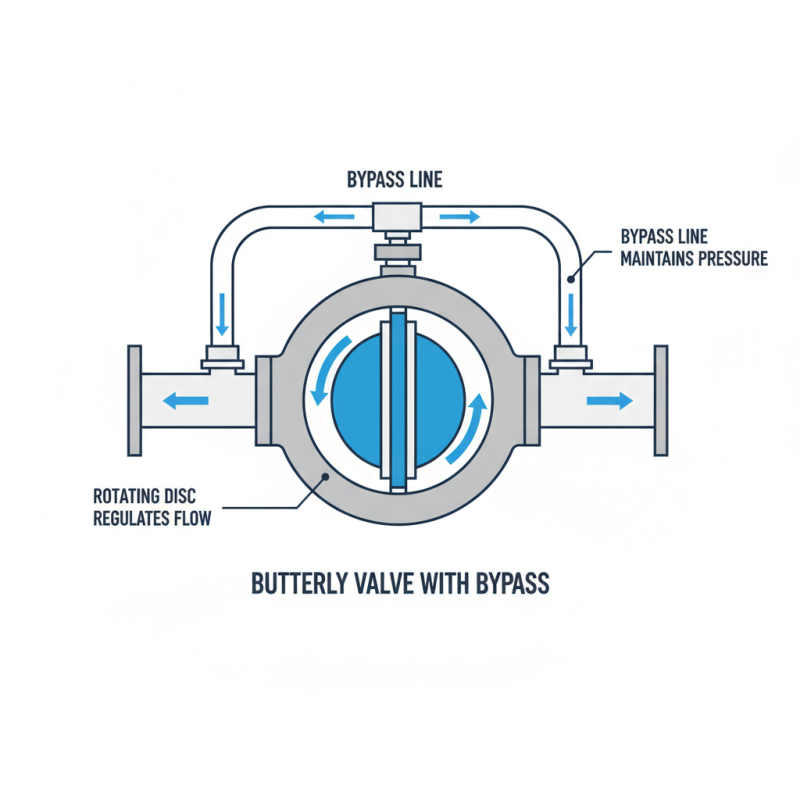

A butterfly valve with bypass is a type of flow control device. It features a central disc that pivots to regulate fluid passage. The bypass allows fluid to flow even when the valve is closed. This design can help maintain a consistent flow rate.

Typically, the bypass is a smaller diameter pipe connected to the main line. This allows fluid to circulate, preventing pressure buildup when the valve is shut. It can be crucial in systems where pressure control is vital.

Installing a butterfly valve with bypass can save energy and reduce wear on the system. However, improper placement may lead to inefficiencies. Regular checks are essential to ensure performance. Understanding the valve’s mechanics can help the user make informed decisions.

A butterfly valve with bypass consists of a few key components. The main part is the disc, which rotates to regulate flow. The disc’s position dictates the flow rate, making it efficient for various applications. Another crucial element is the bypass line. This allows fluid to flow around the valve when it is closed. This feature helps maintain pressure and prevents system damage.

The actuator is critical as well. It controls the opening and closing of the valve. Actuators can be manual or automated. An automated actuator increases precision and efficiency. According to industry studies, using automated butterfly valves can reduce operating costs by up to 30%.

Yet, even with these advancements, some issues remain. Maintenance can become challenging if the bypass line isn’t kept clear. Regular inspections are essential. Failure to maintain can lead to leaks or inefficient operation. Professionals must ensure all components function seamlessly. Understanding these details can drive better performance in various systems.

A butterfly valve with bypass is an important component in many industrial systems. It allows for efficient control of fluid flow. Understanding its operation can improve system performance significantly.

The bypass feature is crucial. It enables flow around the main valve when it is closed. This keeps processes stable and prevents pressure buildup. According to a recent report by the International Society of Automation, effective flow control can enhance operational efficiency by up to 30%. This is particularly important in applications like water treatment and chemical processing.

When the butterfly valve is in operation, the disc rotates to open or close flow paths. This design minimizes resistance and saves energy. However, improper installation can lead to leaks or inefficient flow. Regular maintenance is required to ensure longevity and optimal performance. It's essential to monitor valve conditions regularly and address any signs of wear or malfunction.

A bypass butterfly valve is an innovative solution in fluid control. It combines a standard butterfly valve with a bypass line. The bypass allows for reduced flow when the main valve is fully closed. This feature is particularly helpful in systems requiring flow regulation and pressure maintenance.

These valves are widely used in various applications. They excel in water treatment plants and HVAC systems. Their compact design saves space while providing effective flow control. Moreover, maintenance becomes easier, as the bypass enables online servicing of the main valve.

**Tip:** When installing a bypass butterfly valve, ensure it aligns properly with your system’s flow direction. Misalignment can lead to operational issues.

Another advantage is energy efficiency. By maintaining a minimal flow, these valves help reduce energy costs in industrial processes. However, selecting the wrong size may lead to underperformance.

**Tip:** Regularly check for leaks in the bypass line. This can prevent significant losses in your system and keep operations running smoothly.

Consider the application requirements carefully. A valve that works in one scenario may not perform well in another. Reflect on your specific needs when choosing a bypass butterfly valve.

Butterfly valves with bypass systems are essential in various industrial applications. Their maintenance is critical for ensuring longevity and performance. Regular checks can prevent larger issues down the line. According to a report from the Valve Manufacturers Association, improper maintenance leads to a significant increase in valve failure rates.

Operators must inspect seals and seats frequently. A worn seal can lead to leaks, which may disrupt the entire system. The bypass mechanism should also be monitored, as it controls flow even when the main valve is closed. Ignoring this can result in decreased efficiency and increased operational costs. Data from engineering studies indicate that nearly 30% of flow control issues arise from inadequate maintenance practices.

In addition, lubrication of moving parts is crucial. Insufficient lubrication can cause wear and tear. Some maintenance crews overlook this essential step, which can lead to sticky operations and malfunction. Regular training sessions on maintenance practices can reinforce the importance of detailed inspections. Inconsistent procedures may create gaps in the routine checks. Establishing a comprehensive maintenance schedule can mitigate these risks.