Leave Your Message

When considering piping systems, selecting the right valve is crucial. The Ggg40 Butterfly Valve stands out for its efficiency and reliability. According to a recent industry report, the global butterfly valve market is projected to reach USD 7.5 billion by 2025, highlighting its growing demand.

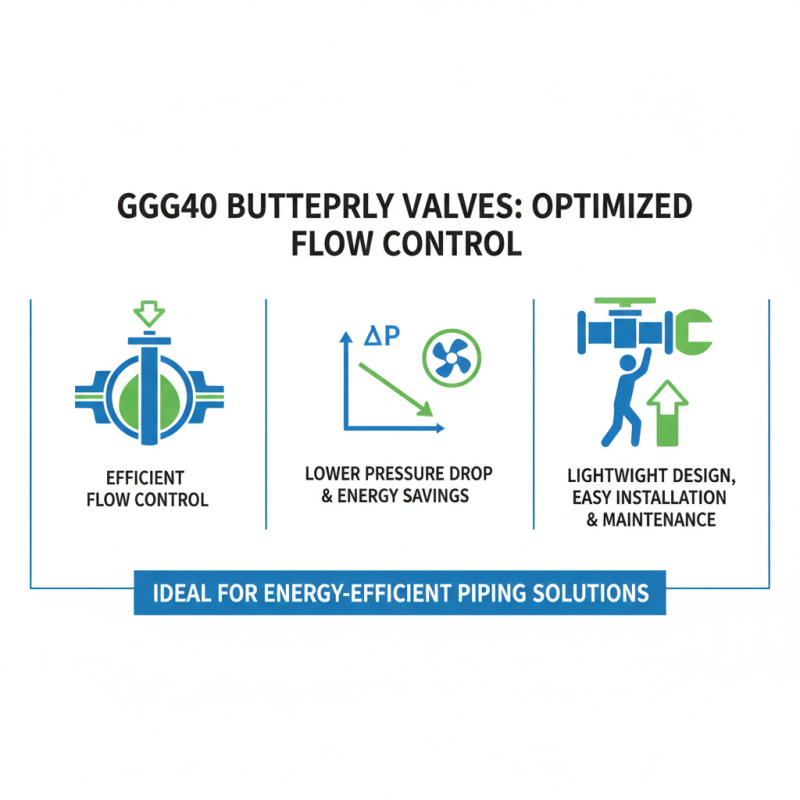

The Ggg40 Butterfly Valve specifically offers excellent performance under various pressures. It is designed for easy installation and maintenance. This valve's lightweight design reduces the overall load on piping systems. Its durability ensures a long service life, which is essential in industrial applications.

However, some may overlook the importance of valve selection. The wrong choice can lead to costly failures. Investing in the Ggg40 Butterfly Valve mitigates this risk. By focusing on materials and design, users can benefit from improved flow control and reduced downtime. Overall, the Ggg40 Butterfly Valve is a smart choice for those looking to enhance their piping solutions.

The Ggg40 butterfly valve is an excellent choice for various industrial applications. Its design features a lightweight body, making it easy to install and maintain. The valve’s robust construction allows it to withstand high pressure and temperature fluctuations. This durability is crucial for industrial settings, where equipment must endure harsh conditions.

One major advantage of the Ggg40 butterfly valve is its flow efficiency. The circular disc design minimizes resistance, ensuring that fluids pass through with ease. This design reduces energy consumption. In many cases, less energy translates to cost savings. However, improper sizing can lead to flow issues, underscoring the need for careful selection.

Another benefit is versatility. These valves can handle different media, including liquids and gases. Their adaptability makes them suitable for various sectors, from water treatment to chemical processing. Despite their advantages, users often overlook the importance of regular maintenance. Neglecting this can lead to performance drops, proving that even reliable equipment needs attention.

The Ggg40 butterfly valve stands out for its material composition. Made from high-quality cast iron, it ensures strength and longevity. This material can withstand high pressures and harsh conditions. The durability of Ggg40 valves makes them suitable for various applications. They work well in both industrial and commercial settings. Their resistance to corrosion is a significant benefit.

When selecting valves, consider your piping system’s specific needs. A proper fit can enhance efficiency. Check if the valve's design suits your flow requirements.

One important tip: regularly inspect your valves for signs of wear. Early detection can prevent major issues down the line. Make sure to maintain proper lubrication for moving parts. This will aid in keeping the valve functional for years. Ggg40 valves may require occasional adjustments. These small actions can lead to significant improvements in performance.

The Ggg40 butterfly valve is designed to enhance piping system performance significantly.

Its lightweight design reduces installation stress. This is key in modern piping systems, where efficiency is critical.

According to recent industry reports, utilizing lightweight valves can lower installation costs by up to 25%.

This aspect makes the Ggg40 an attractive option.

Another important feature is its high durability. The Ggg40 can withstand extreme pressure and temperature variations.

Studies indicate that valves with durable materials can last up to 15 years longer than traditional counterparts.

This increases reliability in crucial applications. However, some users may face challenges with maintenance,

as wear and tear can occur over time. Regular inspections are essential to avoid unexpected failures.

Flow control is another vital feature. The Ggg40 offers precise throttle capability, providing better fluid regulation.

This is essential for systems that require constant flow rates. Yet, this precision can sometimes lead to underperformance if not calibrated correctly.

Understanding the specific needs of the system is crucial. Oversizing or undersizing valves can impact overall efficiency and functionality.

When it comes to installing a Ggg40 butterfly valve, proper attention to detail is crucial. Start by ensuring that the valve is aligned with the pipes. Any misalignment can cause leaks or damage. Use appropriate gaskets to enhance sealing. Tighten all bolts evenly to prevent uneven pressure on the valve.

**Tips:** Always use a torque wrench. This ensures the correct pressure without over-tightening. Double-check your alignment after installation. It’s easy to overlook this step, but it can lead to future issues.

Maintenance is equally critical for optimal performance. Regularly inspect for any wear and tear. Check the seals and the valve's operation. Dust and debris can accumulate, hindering performance. Cleaning them periodically can extend valve life. Tightening loosened fittings can prevent leaks.

**Tips:** Create a maintenance schedule to track inspections. Don’t ignore warning signs like unusual noises or leaks. Address them promptly to avoid bigger problems later.

| Dimension | Material | Temperature Range (°C) | Pressure Rating (PN) | Installation Type | Maintenance Frequency |

|---|---|---|---|---|---|

| 2 inch | Ductile Iron | -10 to 80 | 16 | Wafer Type | Annual |

| 3 inch | Cast Iron | -20 to 90 | 16 | Lug Type | Semi-Annual |

| 4 inch | Stainless Steel | -50 to 150 | 20 | Wafer Type | Bi-Annual |

| 6 inch | Bronze | -10 to 100 | 16 | Lug Type | Annual |

When considering piping solutions, Ggg40 butterfly valves stand out. Their design allows for efficient flow control. Compared to other valve types, they offer a lower pressure drop. This is crucial in systems where energy savings matter. Many users appreciate their lightweight structure. This ensures easier installation and maintenance.

However, not all applications suit a Ggg40 butterfly valve. In high-pressure scenarios, other valve types may perform better. Gate valves, for example, provide better sealing capabilities. They handle higher pressures with minimal leakage. Yet, they can be bulkier and require more space. Users often face a trade-off between size and performance.

Additionally, the material composition merits attention. Ggg40 valves may face corrosion issues in certain environments. Proper material selection is vital for longevity. Another factor is the operating environment. Extreme temperatures can hinder performance. Adjusting for these variables is an ongoing challenge for engineers. Careful assessment is necessary to ensure optimal functionality.