Leave Your Message

Choosing the right Rubber Seat Butterfly Valve is crucial for various applications. Experts like John Smith, a renowned valve specialist, state, “Finding the right valve can save costs and enhance efficiency.” With valves being essential in fluid control, an improper choice can lead to leakage or performance issues.

When selecting a Rubber Seat Butterfly Valve, consider factors like pressure ratings and flow requirements. These valves are known for their durability and reliability. A poor selection may result in frequent replacements, causing unforeseen expenses. Each application has unique needs, making it vital to assess specific requirements.

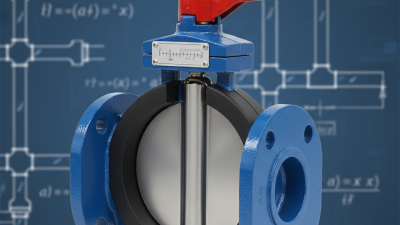

Understanding the construction of the Rubber Seat Butterfly Valve is equally important. The rubber seat enhances sealing, but it can wear over time. Regular maintenance can mitigate this issue. However, some may overlook it, leading to complications later. Thoughtful consideration and expert consultation are key to making an informed decision.

Rubber seat butterfly valves are essential components in various piping systems. They control the flow of liquids and gases with ease. These valves are known for their durability and efficiency. Understanding their basics helps users make informed choices.

When selecting a rubber seat butterfly valve, focus on the application. The size and pressure requirements matter significantly. A small valve might not handle high pressure well. Conversely, an oversized valve can lead to inefficiency. Know your system’s specifications well.

Tips: Always consider the temperature range of the application. Rubber can degrade at high temperatures. Check material compatibility too. Some chemicals may damage the rubber. Regular maintenance extends the valve's lifespan.

In addition, evaluate the installation space. Ensure enough room for valve operation. Sometimes, tight spaces limit valve choices. This consideration is critical but often overlooked. It’s essential to balance functionality and installation needs for optimal performance.

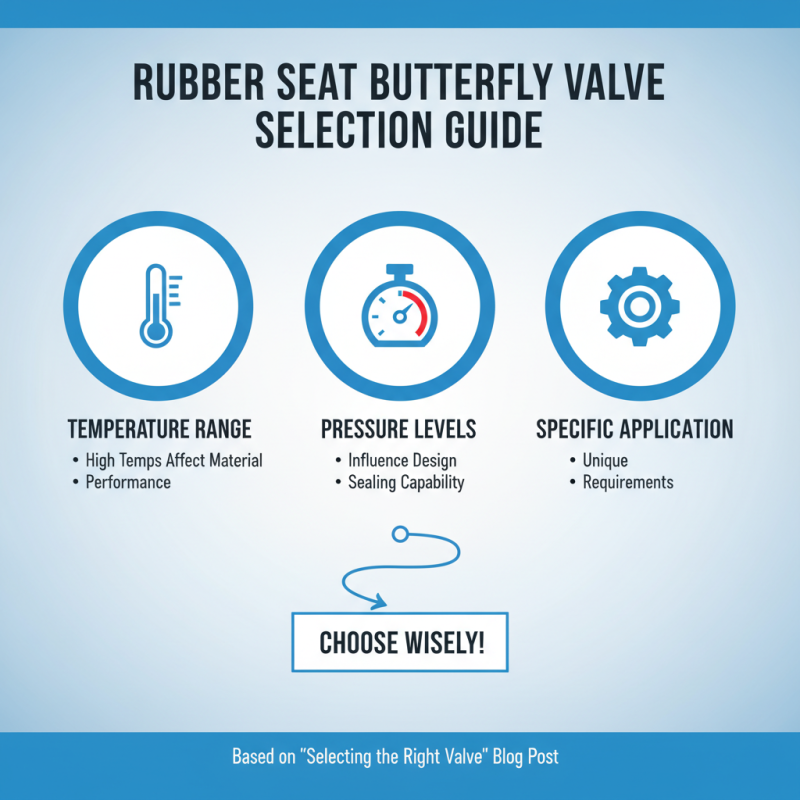

When selecting the right rubber seat butterfly valve, understanding your specific application is essential. Each use case may have unique requirements. Consider the temperature range of your process. High temperatures can affect the valve's material and performance. Additionally, think about the pressure levels your valve will encounter. This can influence the design and sealing capability.

Another crucial factor is the medium that the valve will control. Different fluids can react differently with materials. Ensure the rubber seat is compatible with your flow medium. You may need to conduct tests to confirm this compatibility. Some users forget this step, leading to operational failures.

Installation space must also be considered. Not all settings provide ample room for a butterfly valve. Determine if you need a compact design. After evaluating these specifics, you can better identify the right valve model for your needs. Reflecting on these details may reveal aspects you hadn’t considered. Adjustments might be necessary based on your findings.

When choosing a rubber seat butterfly valve, evaluating the size and pressure ratings is crucial. The right size ensures optimum flow and efficiency. A valve that is too large can lead to turbulence and inefficient operation. Conversely, a valve too small may restrict flow, causing pressure drops. According to industry data from the Valve Manufacturers Association, about 30% of system failures result from incorrect valve sizing.

Pressure ratings are equally important. Valves are rated based on their maximum operating pressure. For rubber seat butterfly valves, this usually ranges from 150 to 300 psi. A higher pressure rating indicates better performance in extreme conditions. However, using a valve beyond its ratings can lead to catastrophic failures. A report from the American Society of Mechanical Engineers states that improper valve selection accounts for approximately 25% of maintenance costs in industrial settings.

Selecting the appropriate valve also depends on the medium it will handle. Different materials react differently under pressure. A rubber seat may not perform well in high-temperature environments. Evaluating the compatibility of the valve with the fluid is essential. Some applications require a detailed analysis of pressure drop and flow rate. Take time to understand these factors; a wrong choice can lead to costly operational downtime.

When selecting a butterfly valve, material choice is crucial. The rubber used can impact durability and performance. Natural rubber, for example, offers flexibility, but it may degrade under harsh conditions. Synthetic options often provide better resistance to temperature changes and chemicals.

Consider the environment where the valve will be installed. Exposure to UV light or extreme heat can weaken some rubber types over time. While considering cost, cheaper materials might save money initially, but they can lead to higher replacement costs later on. It’s a balancing act between upfront expenses and long-term reliability.

Not every situation is straightforward. Sometimes, trial and error is unavoidable. A valve that seems perfect on paper may not perform well in practice. Prior research helps, but field tests can reveal unforeseen issues. Always have a contingency plan ready for unexpected failures in the rubber material.

| Material Type | Temperature Range (°C) | Chemical Resistance | Durability (Years) | Cost ($/Unit) |

|---|---|---|---|---|

| EPDM | -40 to 120 | Good | 10-15 | 1.50 |

| Nitrile (Buna-N) | -40 to 100 | Excellent for oils & fuels | 8-12 | 1.20 |

| Silicone | -50 to 200 | Poor | 10-20 | 2.00 |

| Neoprene | -40 to 100 | Good | 10-15 | 1.80 |

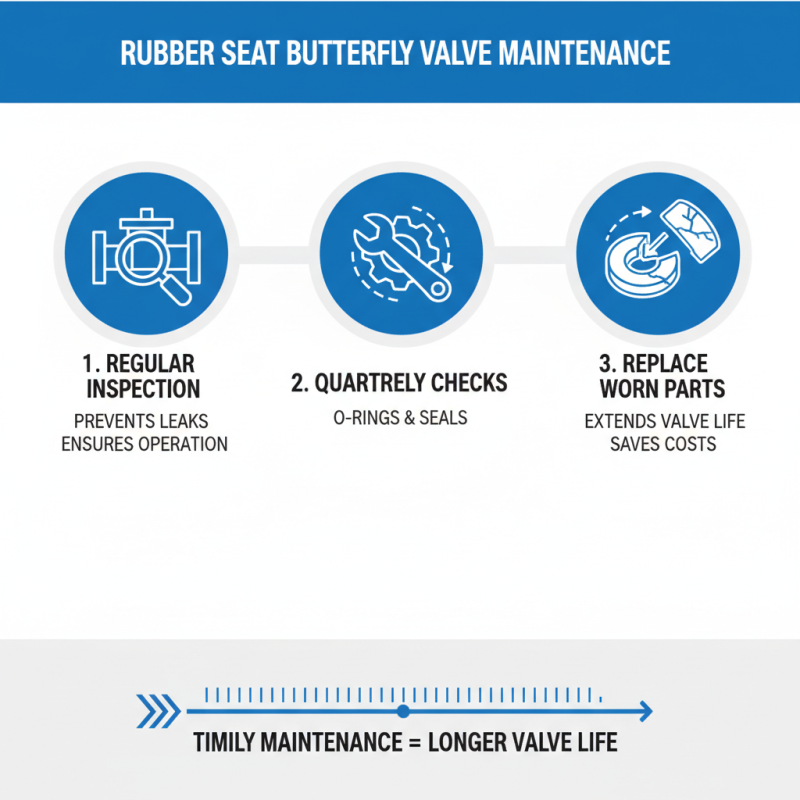

When selecting a rubber seat butterfly valve, maintenance is crucial. Regular inspection can prevent leaks and ensure proper operation. Industry studies show that regular maintenance can extend valve life by up to 30%. O-rings and seals should be checked every quarter. Replacing worn parts timely can save costs in the long run.

Installation is equally important. Incorrect fitting can lead to early failures. Follow the manufacturer's guidelines carefully. A report from the Valve Manufacturers Association indicates that improper installation accounts for 25% of valve failures. Ensure that the valve is aligned correctly. Misalignment often causes unnecessary wear. It’s important to take this step seriously. Remember that even small oversights can lead to big problems.

Temperature and pressure ratings must match your system's needs. Underestimating these factors can cause valve failure. A study found that 15% of premature valve failures resulted from disregarding specifications. Consider the environment as well. Corrosive conditions can reduce longevity. Regular training for personnel on installation and maintenance can improve reliability.