Leave Your Message

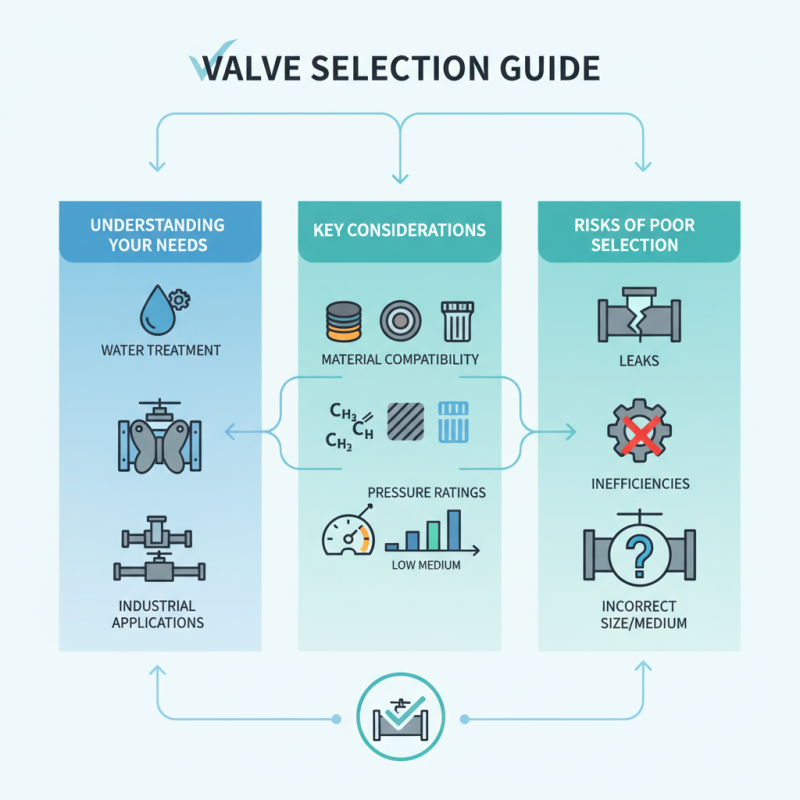

Choosing the right Rubber Seat Butterfly Valve can seem daunting. Industry expert John Smith emphasizes, “Understanding your application is key.” This statement underscores the importance of selecting a valve that fits specific needs.

Rubber Seat Butterfly Valves provide flexibility and leak-proof performance. They are ideal for various applications, from water treatment to chemical processing. However, not every valve suits every task. Understanding the material compatibility and pressure ratings is crucial.

Sometimes, people underestimate the impact of incorrect valve selection. Choosing poorly can lead to leaks or inefficiencies. A three-inch valve might seem standard, but if it doesn’t handle the right medium, problems arise. It's essential to reflect on these details to ensure optimal performance.

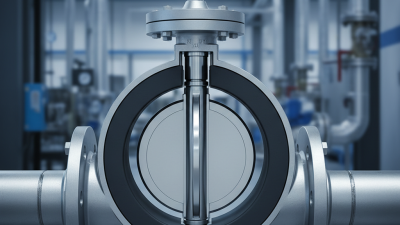

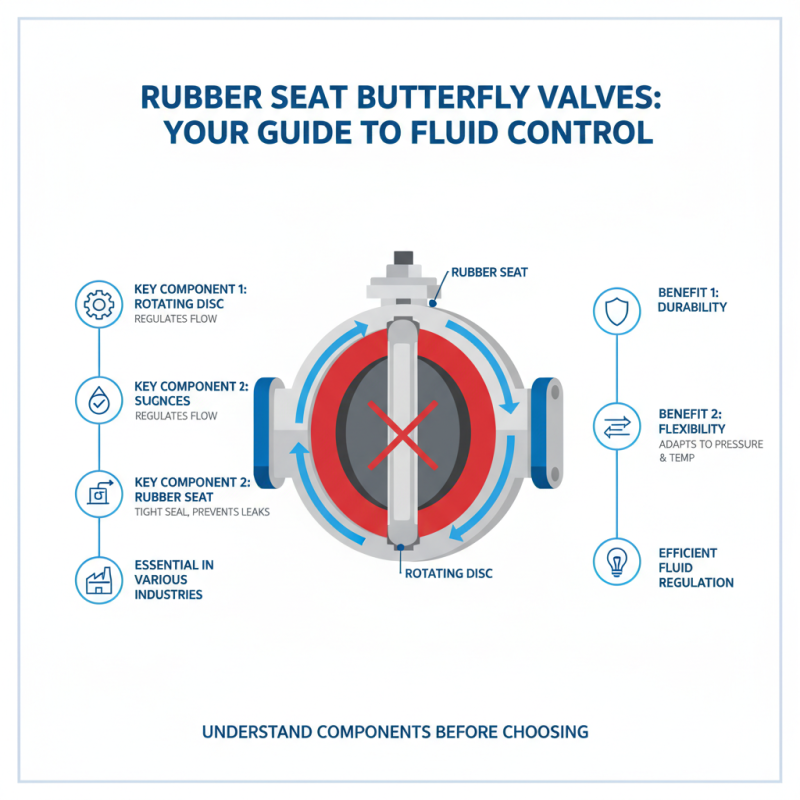

Rubber seat butterfly valves are essential in various industries. They regulate fluid flow efficiently. Understanding their components is crucial before making a choice. These valves consist of a rotating disc and a rubber seat. The rubber seat ensures a tight seal, preventing leaks. This design offers durability and flexibility, adapting to different pressures and temperatures.

When choosing a rubber seat butterfly valve, consider the application. Factors like fluid type and pressure ratings matter. Not all valves work well with abrasive or corrosive materials. Some may wear out faster than others. It’s important to research materials used in construction. Sometimes, an overlooked detail can lead to failures.

Another aspect to note is maintenance. Regular checks can prolong a valve's life. Neglect can lead to blockages or leaks. Understanding the basics helps in making informed decisions. Comfort in knowing the specifics can guide users in selecting the right valve for their needs.

When selecting a rubber seat butterfly valve, understanding key factors is crucial. The valve's design plays a vital role in performance. The choice of materials affects durability and functionality. For instance, EPDM rubber can handle high temperatures, while NBR is better for low temperatures. According to industry reports, over 40% of valve failures are due to material incompatibility.

Size is another critical aspect. A valve must fit the system's specifications, including pipe diameter and pressure rating. Oversized or undersized valves can lead to inefficiencies or failures. Research indicates that nearly 30% of installations do not consider this factor, leading to costly rework.

Consider the application as well. Different environments require specific features. For example, corrosive fluids may need special coatings. Unfortunately, many users overlook this, resulting in poor valve performance.

Regular maintenance is essential too. The industry standard suggests inspecting valves every six months. Neglecting this can lead to unexpected outages. Understanding these factors can significantly enhance operational efficiency.

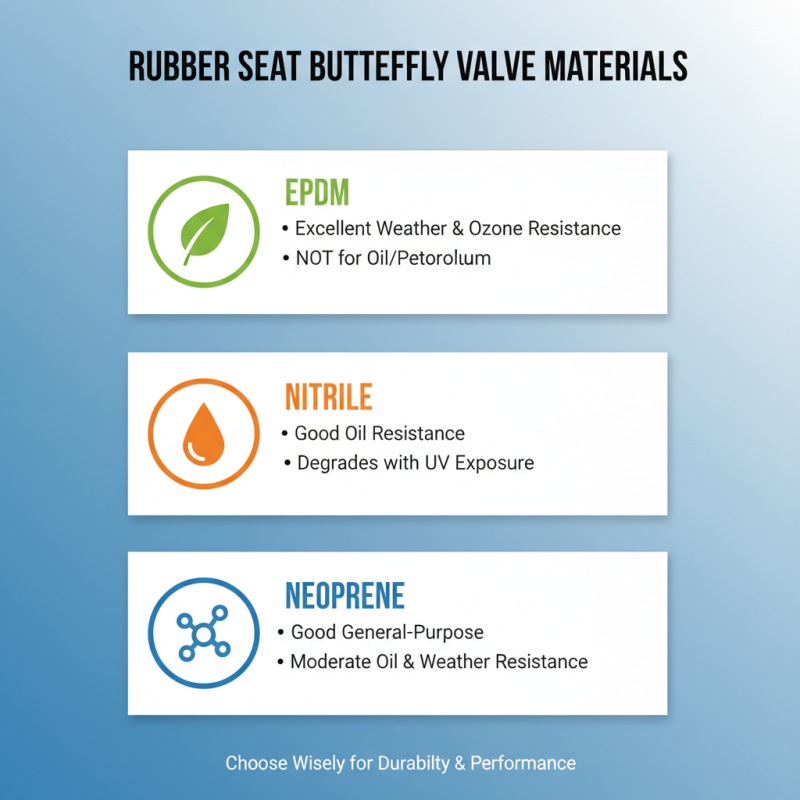

When selecting a rubber seat butterfly valve, material choice is crucial. Different materials offer varying levels of durability and performance. Common options include EPDM, Nitrile, and Neoprene. EPDM provides excellent weather and ozone resistance. However, it may not be suitable for oil or petroleum applications. Nitrile is a solid choice for oil resistance but can degrade under UV exposure.

Neoprene is durable and versatile. It performs well in a range of temperatures but lacks the best resistance to certain chemicals. Users must also consider the operating environment. Temperature fluctuations can impact the valve’s lifespan. For example, extreme heat may cause rubber to lose flexibility.

Regular maintenance can help extend the valve's lifespan, regardless of material. It's essential to check for wear and tear periodically. Remember, the wrong material can lead to leaks and failures. Take the time to analyze specific needs. This ensures that the chosen valve material aligns with the application.

When selecting a rubber seat butterfly valve, evaluating size and pressure ratings is crucial. The valve's size must match the pipeline dimensions. A mismatch can cause leaks or flow issues. Conversely, an oversized valve can lead to turbulence, affecting efficiency. According to industry reports, proper sizing prevents pressure loss, which is essential in applications like water treatment and chemical processing.

Pressure ratings also play a vital role. These valves come in different pressure classes, which indicate their maximum operating pressure. For example, standard valves may handle pressures up to 150 psi. Higher pressure ratings, like 300 psi, are available for more demanding applications. Neglecting the pressure requirements can result in valve failure. This has been documented in several case studies, showing increased maintenance costs due to improper valve selection.

It’s worth noting that the material quality of the rubber seat also impacts performance. The choice between EPDM, Nitrile, or other compounds is determined by the medium it will handle. Moreover, the different temperature ranges of materials can affect durability and reliability. In some instances, users underestimate the importance of these calculations. A thorough evaluation can save time and money in the long run. Adopting a comprehensive approach to sizing and ratings helps prevent unnecessary operational challenges.

Maintaining a rubber seat butterfly valve is essential for its longevity. Regular inspection can help identify wear and tear early. Data shows that improper maintenance can reduce valve life by over 40%. Regular cleaning prevents debris from causing seals to degrade. A simple rinse can make a significant difference.

Lubrication is also crucial. Many valves require periodic lubrication to ensure smooth operation. Dry seals and components can lead to excessive friction. This not only shortens life but can cause sudden failures. Aim to lubricate every few months, depending on use. Monitor the environment as well. Extreme temperatures can warp rubber materials.

Finally, don't ignore the importance of proper installation. Misalignment can lead to premature wear. If a valve is not seated correctly, it may operate inefficiently. Record any previous issues and keep detailed maintenance logs. These practices can improve valve performance and extend its service life.

| Parameter | Description | Maintenance Tips | Expected Lifespan |

|---|---|---|---|

| Size | Commonly available sizes range from 2" to 12" | Regularly check for wear and tear | 5-10 years depending on usage |

| Material | Rubber seat typically provides good sealing | Inspect the rubber for cracks and deformities | 5-7 years with proper care |

| Pressure Rating | Common ratings from 150 PSI to 300 PSI | Avoid exceeding recommended pressure limits | 3-8 years under high pressure |

| Temperature Range | Typically from -10°F to 180°F | Ensure the temperature is within limits to prevent damage | 4-6 years in extreme conditions |

| Application | Used in water, oil, and gas applications | Regularly clean and lubricate the valve | 7-10 years with optimal operation |