Leave Your Message

In marine applications, the choice of valves is crucial. The Sea Water Butterfly Valve stands out due to its unique properties. Experts like Dr. John Lewis emphasize its importance. He stated, "A reliable valve is essential for marine longevity."

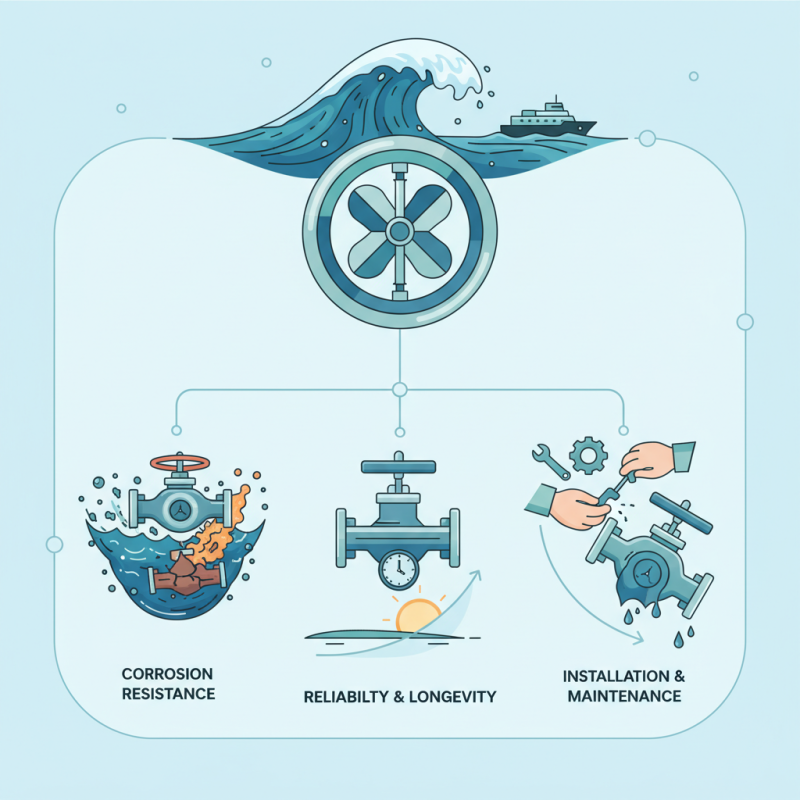

Corrosion resistance is a key feature of the Sea Water Butterfly Valve. Its design helps prevent leaks and failures. In harsh seawater environments, traditional valves often falter. Yet, a quality butterfly valve can provide peace of mind.

However, challenges persist. Installation processes can be tricky. Some may overlook regular maintenance. This can lead to bigger issues down the line. Choosing a Sea Water Butterfly Valve demands careful thought. It’s about balancing performance with reliability.

Choosing a sea water butterfly valve for marine applications is wise. These valves offer unique advantages in harsh environments. They resist corrosion very well due to their specialized materials. This makes them ideal for saltwater systems. Their lightweight design allows easier installation. They perform reliably under high-pressure conditions.

In marine settings, reliability is crucial. Sea water butterfly valves can handle frequent cycling. This feature enhances operational efficiency. However, installation errors can lead to severe problems. Always double-check connections and seals. Corrosion may still occur if not properly maintained. Regular inspections help prevent failures.

Tips for maintenance: Clean the valves regularly. Use fresh water to rinse away salt. Look for signs of wear and tear. Replacing worn parts early can save costs. Ensure that operators are trained adequately. An inexperienced hand can cause unplanned downtime.

Choosing the right valve for marine applications is crucial. Sea water butterfly valves are particularly designed for this environment. Their material composition significantly affects performance and longevity. Corrosion resistance is a major factor in these applications. According to a recent report, nearly 70% of valve failures in marine settings are due to corrosion-related issues.

The common materials used in sea water butterfly valves include stainless steel and bronze. These materials have proven effective against sea water's corrosive nature. Studies indicate that duplex stainless steels can enhance service life by up to 50% over standard stainless steels. This is essential, given the harsh marine conditions these valves face. Additionally, Teflon coatings can further improve resistance to corrosive agents, ensuring a reliable seal.

However, the ideal material may vary by application. Factors such as temperature and water salinity influence material selection. Not every material provides sufficient resistance. This leads to reflections on how failures occur due to material misalignment with application needs. Proper research and testing are critical to avoid costly downtime. Accurate material selection ultimately affects system reliability and safety in marine operations.

| Material | Corrosion Resistance | Temperature Range (°C) | Typical Applications |

|---|---|---|---|

| Duplex Stainless Steel | Excellent | -50 to 250 | Marine Industry, Oil & Gas |

| Bronze | Good | -20 to 200 | Shipping, Water Treatment |

| PVC | Fair | 0 to 60 | Aquarium, Pool Systems |

| CPVC | Very Good | 0 to 90 | Chemical Processing |

| Titanium | Exceptional | -100 to 400 | Marine Exploration, Research |

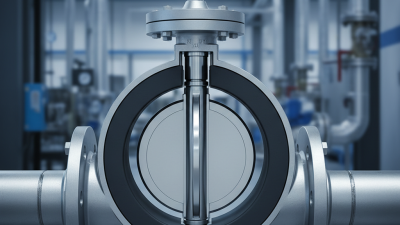

Sea water butterfly valves play a crucial role in marine systems. Their design is simple yet effective. These valves are often used for controlling flow in seawater applications. They offer reliability and durability, essential for harsh marine environments. Made from corrosion-resistant materials, they withstand the impact of salty water.

Operational efficiency is vital for marine applications. Butterfly valves ensure smooth flow control, which can enhance system performance. They can be operated easily, even under intense pressure. However, improper maintenance can lead to inefficiencies. Regular assessments are critical to ensure they function well over time. Neglecting these tasks could lead to costly repairs.

Heat and pressure fluctuations can challenge any valve. Sea water butterfly valves are designed to manage these variables effectively. They can fail if not monitored frequently. Operators must be diligent to avoid potential breakdowns. Overall, while these valves are efficient, they require attention to maintain that efficiency in the demanding marine environment.

Maintaining sea water butterfly valves in marine applications is crucial for optimal performance. These valves face corrosive environments, which can lead to faster degradation. Regular inspections are necessary. Check for signs of wear or corrosion. Pay attention to seals and seats, as they are highly susceptible to marine conditions.

Proper lubrication is essential. Use compatible lubricants to avoid damaging the valve materials. Tips: Ensure all valves are operated periodically, even if not in use. This prevents stiffness and maintains proper sealing. Over time, accumulated salt can affect valve function. Clean the surfaces regularly to prevent crust buildup.

Maintenance can be daunting. Some operators forget to document their maintenance activities. Keep a log of inspections and repairs. Analyze patterns and identify potential issues early. This proactive approach can save time and resources. Sometimes, overlooking minor issues leads to costly repairs later. Staying vigilant is key.

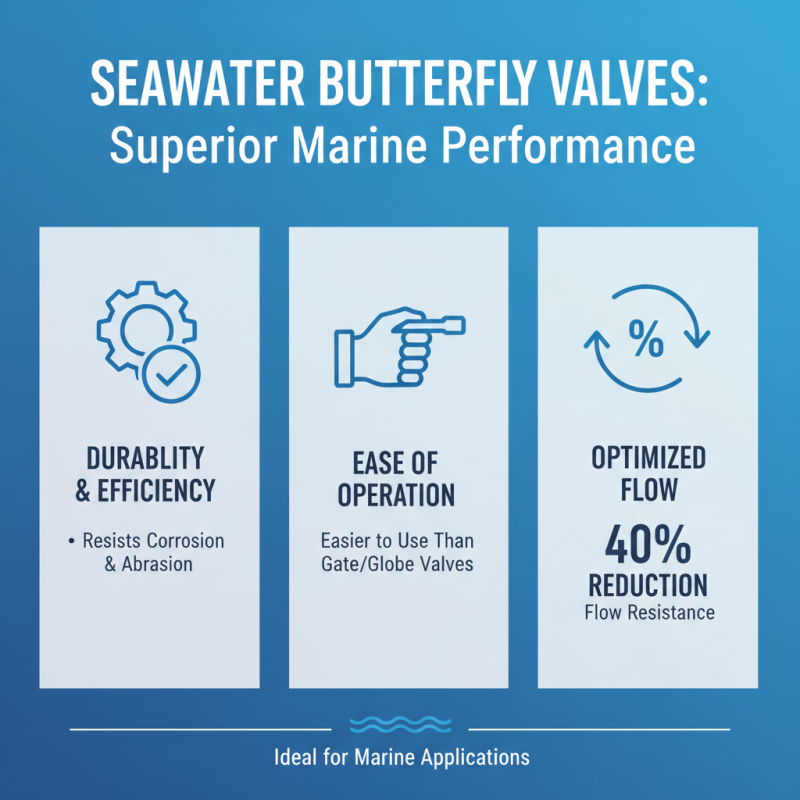

When considering marine applications, sea water butterfly valves stand out in durability and efficiency. Compared to traditional gate or globe valves, they are easier to operate. Industry reports indicate that butterfly valves can reduce flow resistance by up to 40%. This attribute is crucial when dealing with sea water, which can be corrosive and abrasive.

Manufacturers often cite that butterfly valves are approximately 40% lighter than gate valves. This weight difference makes installation simpler on vessels, saving both time and labor costs. However, some engineers express concern over their sealing adequacy in high-pressure situations. Despite improved designs, this remains a relevant consideration in specific marine environments.

Furthermore, sea water butterfly valves are more cost-effective over time. They typically require less maintenance and have a longer lifespan when correctly installed. However, the long-term performance could vary significantly with fluctuating water temperatures and salinity levels. Each marine application is unique, and careful evaluation is needed when selecting the appropriate valve type for specific conditions.