Leave Your Message

When it comes to managing fluid flow in industrial applications, selecting the right equipment is crucial for efficiency and reliability. Among various options, the Big Size Butterfly Valve stands out due to its unique design and operational advantages. These valves are not only capable of handling large volumes of fluids but also offer ease of operation and compactness, making them ideal for various processes. As industries evolve and face new challenges, knowing how to choose the best Big Size Butterfly Valve tailored to your specific needs is imperative.

In this guide, we will explore essential factors to consider when selecting a Big Size Butterfly Valve. From understanding the different types and materials available to assessing your application requirements, each aspect plays a significant role in making an informed decision. Whether you are dealing with high-pressure systems or systems requiring precise flow control, finding the right valve can significantly enhance your operations. Join us as we delve into the critical elements that will help you identify the most suitable Big Size Butterfly Valve for your business needs, ensuring optimal performance and longevity.

In 2025, choosing the right big size butterfly valve requires understanding the various types available on the market. The two main categories are concentric and eccentric butterfly valves. Concentric valves feature a design where the disc rotates around a central shaft, providing a straightforward operation ideal for applications requiring tight sealing. They are commonly used in water distribution systems and other low-pressure applications.

On the other hand, eccentric butterfly valves come in two subtypes: single and double eccentric. These valves are designed with an offset shaft that allows for a more efficient sealing mechanism and reduced wear on the valve seat. Single eccentric valves are particularly effective in handling higher pressures and can manage larger fluid flows, making them suitable for industrial applications. Double eccentric valves further enhance performance by providing even greater sealing effectiveness and durability, ideal for extreme conditions found in chemical processing or oil and gas sectors. Evaluating your specific needs against these types will help in selecting the best valve for your requirements.

When selecting a big size butterfly valve for your application, it's essential to consider several key factors to ensure optimal performance and reliability. First, understand the valve's specifications, including pressure ratings, size, and the material of the valve. These parameters influence the valve's ability to handle different media, whether liquid or gas, as well as its durability under various conditions.

Another critical consideration is the application environment. Assess factors like temperature extremes, corrosive substances, and the physical layout of the installation site. For instance, certain materials may be better suited for high-corrosion applications, while others may handle temperature fluctuations more effectively. According to industry reports, the global industrial valve market is expected to experience significant growth, highlighting the increasing demand for efficient and high-performance valves in various sectors.

**Tips:** Always verify the valve’s compliance with relevant industry standards. Engaging with manufacturers for specific recommendations based on your application can lead to better choices. Additionally, consider maintenance requirements; some butterfly valves feature designs that facilitate easier inspection and servicing, ensuring long-term efficiency.

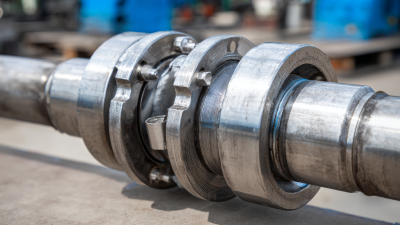

When selecting a big-size butterfly valve, understanding material specifications is crucial, especially when facing harsh conditions. The environment in which the valve will operate can significantly impact its performance and durability. For example, valves exposed to high temperatures and corrosive substances require materials that can withstand such challenges. Common materials include stainless steel, which offers excellent resistance to corrosion, and ductile iron, known for its strength and resilience. Evaluating the specific needs of your application is the first step in ensuring optimal valve selection.

Additionally, consider the valve design and sealing mechanisms, which can further influence functionality in extreme environments. For instance, a valve with a resilient elastomer seal may perform better in applications involving fluctuating temperatures and pressures compared to a standard metal-to-metal seal. Therefore, matching the valve material and design with environmental factors such as temperature, pressure, and potential chemical exposure is essential for achieving long-lasting operation and reliability in harsh conditions. Understanding these specifications enables users to make informed decisions, ultimately enhancing system efficiency and safety.

When selecting a big size butterfly valve, assessing flow characteristics is crucial to ensure optimal performance. Understanding how the valve interacts with the fluid flow can significantly impact its efficiency, reliability, and longevity. Factors such as flow rate, pressure drop, and fluid viscosity play pivotal roles in determining the right butterfly valve for specific applications. By mapping out these characteristics, engineers can identify the appropriate size and type of valve that aligns with the system requirements and performance expectations.

Moreover, achieving optimal performance also involves considering the valve's design and material. Butterfly valves come in various configurations, including concentric, eccentric, and double eccentric designs, each suited for different flow conditions. Selecting the right valve material is equally essential, as it must withstand the specific environmental and operational conditions—such as temperature, pressure, and chemical exposure—of your application. By prioritizing flow characteristics and incorporating these considerations into your decision-making process, you can enhance the efficiency and effectiveness of your butterfly valve system.

When selecting a big size butterfly valve, understanding industry standards and certifications is crucial for ensuring the quality and safety of your selection. Various organizations, such as the American Petroleum Institute (API) and the International Organization for Standardization (ISO), set forth guidelines that manufacturers must adhere to. These standards cover materials, design, testing, and performance, ensuring that the valves can withstand the required pressures and temperatures in various industrial applications.

Additionally, certifications like the American Society of Mechanical Engineers (ASME) and the European Pressure Equipment Directive (PED) signify that a valve has undergone rigorous testing and meets safety regulations. When evaluating potential suppliers, it is essential to inquire about their compliance with these industry standards and certifications. This will not only minimize the risks associated with valve failure but also enhance the reliability of your overall system, ensuring that it operates efficiently and safely in demanding environments.

| Dimension (inches) | Material | Max Pressure (PSI) | Temperature Range (°F) | Industry Standard | Certification |

|---|---|---|---|---|---|

| 6 | Cast Iron | 150 | -20 to 250 | ASME | API 609 |

| 8 | Ductile Iron | 200 | -20 to 300 | ANSI | CE |

| 10 | Stainless Steel | 300 | -30 to 350 | BSI | ISO 9001 |

| 12 | PVC | 75 | 0 to 140 | DIN | NSF |