Leave Your Message

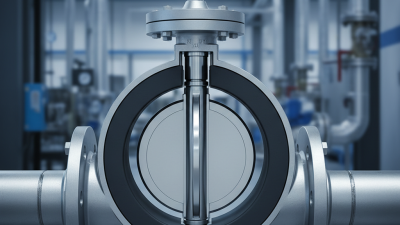

In industrial applications, safety remains a top priority. The Butterfly Valve With Locking Device is gaining attention for its reliability. Experts like John Smith, a renowned valve specialist, emphasize its importance. He states, "A locking device adds a crucial layer of safety in critical operations." This feature mitigates the risk of accidental opening.

Many firms overlook the significance of a locking mechanism. This oversight can lead to dangerous situations. When valves are not properly secured, the consequences can be severe. Locking devices ensure that the valve remains closed when needed. This is essential in high-pressure systems or hazardous environments.

The Butterfly Valve With Locking Device serves as a safeguard. However, there are those who still question its necessity. The industry must reflect on these doubts. Understanding the balance of safety and efficiency is vital. Continuous improvement in valve technology, including locking devices, is necessary for all professionals in the field.

When selecting a butterfly valve, understanding locking devices is crucial for safety. Locking devices prevent accidental operation. This is particularly important in high-pressure systems. A valve left open can lead to spills or leaks. Therefore, the added safety feature of a locking mechanism is essential.

Tips: Always check the locking mechanism before use. Make sure it functions correctly. Inspecting it regularly can prevent mishaps.

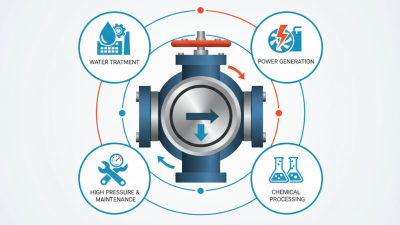

Consider the environment where the valve will operate. High temperatures or corrosive substances can affect the locking device's performance. Choose materials that withstand such conditions. This attention to detail ensures reliability in critical applications.

Tips: Look for valves designed for your specific conditions. Consult with professionals to determine the best choice. A small oversight can lead to significant problems later. Proper installation and maintenance are vital. A well-locked butterfly valve protects against unwanted incidents.

In industrial settings, safety is paramount. Butterly valves play a crucial role in controlling flow. A locking device adds an essential layer of protection. It prevents accidental opening or closing during maintenance. This is critical where high-pressure fluids are involved.

Consider the implications of a valve malfunction. Without safety features, a simple error can lead to disasters. The locking mechanism safeguards against this risk. Operators can work with confidence, knowing the system won’t change unexpectedly. It offers peace of mind in high-stakes environments.

However, not all installations consider these features. Many overlook the importance of redundancy in design. Some may feel secure without a locking device. This attitude can lead to oversights. Evaluating safety features is vital for any operational strategy. Without proper reflection, companies may expose themselves to unnecessary risks.

| Feature | Importance | Benefits |

|---|---|---|

| Locking Device | Prevents accidental operation | Increases workplace safety |

| Fail-Safe Design | Ensures valve remains in safe position during failure | Minimizes risk of leaks or bursts |

| Easy Maintenance | Reduces downtime | Saves costs on repairs |

| Corrosion Resistance | Enhances durability | Increases lifespan of the valve |

| Compact Design | Saves space in installations | Allows for more flexible piping layouts |

In industrial applications, safety is paramount. Butterfly valves with locking devices play a crucial role in enhancing operational safety. Reports indicate that around 25% of industrial accidents can be traced back to valve failures. A locking device prevents unintentional valve operation, reducing the risk of such failures.

Locking mechanisms can range from manual locks to automated systems. For example, a study found that employing locking devices can decrease accidental valve manipulation by 40%. This is significant in processes involving high-pressure systems. It ensures that operators cannot change valve positions accidentally, which could lead to hazardous situations.

Moreover, the presence of these devices promotes better compliance with safety protocols. Employees are more mindful when working with equipment that includes locking features. They perceive these valves as reliable and secure. However, not all facilities implement these devices. Some may view them as unnecessary, highlighting gaps in safety awareness. Regular training and processes can alleviate these issues and improve overall safety culture.

When comparing butterfly valves, the choice between locking and non-locking mechanisms is crucial for safety. Locking devices prevent accidental valve changes. A report by the American National Standards Institute (ANSI) indicates that approximately 30% of valve failures are due to accidental repositioning. This underscores the importance of choosing the right mechanism.

Some industries prioritize automation over manual operation. In such cases, non-locking valves may seem appealing. However, a study by the International Society of Automation (ISA) showed that improper valve handling accounted for a notable increase in system downtime. Locking mechanisms offer a clear advantage in high-stakes environments, protecting against both human error and mechanical failure.

The effectiveness of a locking butterfly valve can vary. Some designs might not fully engage under high pressure. This can render the safety feature less effective. Additionally, routine maintenance procedures are vital. Ignoring these can lead to malfunctions. Thus, evaluating the locking mechanism’s reliability is essential for ensuring safety in fluid control systems.

When installing a butterfly valve with a locking device, it’s crucial to focus on proper alignment. Misalignment can cause leaks and eventual failure. Ensure that the valve is level and secured in position before tightening any bolts. Check the manufacturer's guidelines to avoid common pitfalls during installation. Use a torque wrench for consistent tightness, which is often overlooked. A loose valve can lead to dangerous situations.

Another key aspect is to test the locking mechanism after installation. A well-functioning lock ensures safety during operation. If the lock is faulty, it may not hold the valve in place. This can create hazardous conditions. Regular maintenance checks are also essential. Inspect the locking device and the valve for wear and tear over time. It’s easy to forget these details, but they are vital for safety.

Training personnel on proper installation and maintenance is often ignored. Make sure everyone understands the importance of a locking device. Encourage communication about issues or uncertainties during installation. This ensures that safety becomes a shared priority within the team.