Leave Your Message

In the realm of industrial applications, the selection of the right components can significantly impact the overall efficiency and effectiveness of operations. One such critical component is the Ebonite Lining Butterfly Valve, a choice that is becoming increasingly popular due to its durability and reliability in various environments. As noted by industry expert Dr. Emily Carter, "The Ebonite Lining Butterfly Valve exemplifies resilience, offering unparalleled performance even in challenging conditions."

Choosing the optimal Ebonite Lining Butterfly Valve is not merely a matter of preference; it is essential for ensuring that systems operate smoothly and efficiently. With numerous factors to consider, such as pressure ratings, temperature limitations, and fluid compatibility, it becomes paramount to understand the specific needs of an operation. Furthermore, expertise in this niche can lead to a more knowledgeable selection process, ultimately enhancing productivity and reducing maintenance costs.

As we explore the key considerations for selecting the best Ebonite Lining Butterfly Valve, it is important to highlight the critical parameters that need to be examined thoroughly. These include material properties, installation requirements, and long-term performance expectations. Engaging with specialists in the field can provide valuable insights, ensuring that the selected valve meets all operational requirements and contributes to optimal performance.

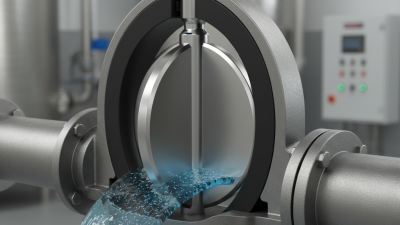

Ebonite lining is a specialized coating used in butterfly valves that enhances their durability and performance.

This rubber-like material is known for its excellent resistance to wear, chemicals, and extreme temperatures, making it an ideal choice for various industrial applications. By incorporating ebonite lining, valves can reduce the risk of corrosion and extend their lifespan significantly,

which ultimately leads to cost savings for businesses.

When selecting an ebonite lining butterfly valve, it is essential to consider the specific operational conditions.

Factors such as temperature, pressure, and the type of fluids being transported can influence the effectiveness of the ebonite lining.

Ensuring that the lining is compatible with the process conditions will optimize valve performance and minimize maintenance needs.

Tips for Choosing Ebonite Lining Butterfly Valves:

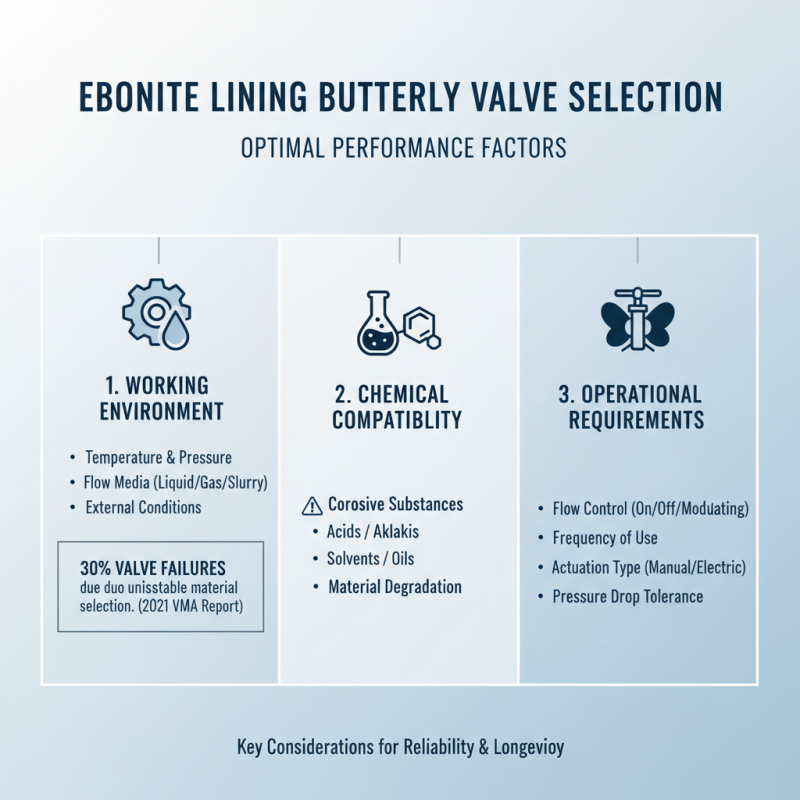

When selecting ebonite lining butterfly valves for optimal performance, several key factors must be taken into consideration. One of the primary aspects is the working environment in which the valves will be deployed. According to the 2021 Valve Manufacturers Association report, nearly 30% of valve failures can be attributed to unsuitable material selection for specific service conditions. Therefore, understanding the chemical compatibility of ebonite with the media it will handle is crucial, especially in industries where corrosive substances are prevalent.

Another significant factor is the sizing and pressure rating of the butterfly valve. Industry guidelines recommend proper sizing based on flow requirements and system pressures to ensure efficiency and reliability. The American National Standards Institute (ANSI) emphasizes that improper sizing can lead to increased turbulence and energy losses, which could reduce overall system efficiency by up to 15%. Incorporating precise calculations and adhering to pressure ratings can drastically improve the longevity and dependability of the valve in demanding applications.

Finally, installation and maintenance considerations should not be overlooked. Proper installation techniques influenced by best practice guidelines can minimize the risks of leaks or operational malfunctions. Regular inspection and maintenance schedules, as advised by the International Society for Automation, can extend the lifespan of butterfly valves and maintain optimal performance across their operational life, averaging a potential increase in lifespan by 20% when executed correctly.

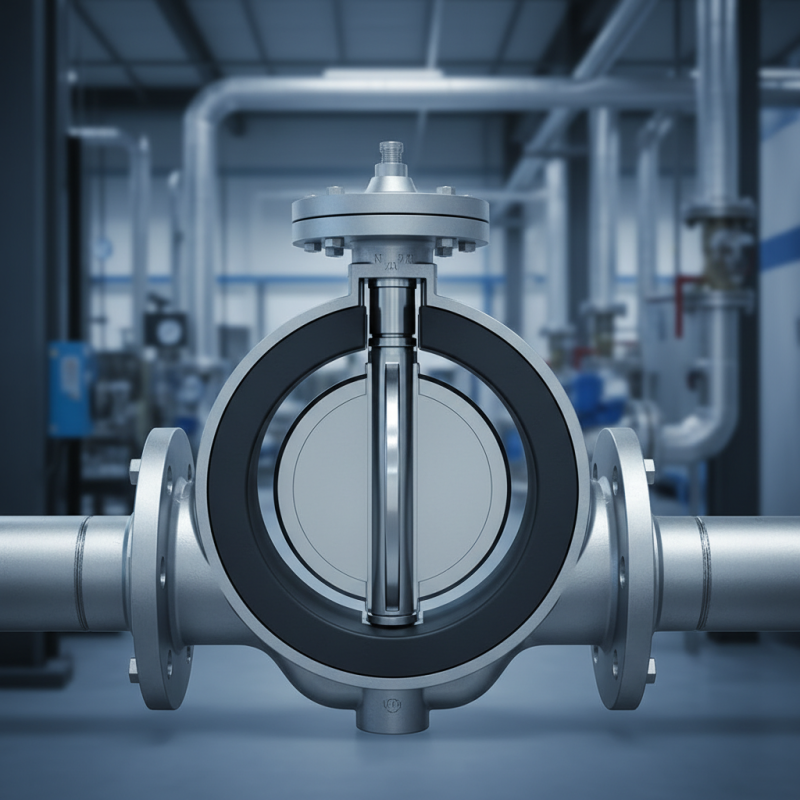

When selecting ebonite lined butterfly valves, understanding performance metrics is essential for ensuring optimal functionality and longevity. Key metrics to consider include the valve's pressure rating, which determines how much pressure the valve can withstand without failure. This is crucial for applications involving various fluid types and operating conditions. Additionally, the flow coefficient (Cv) is a significant factor that indicates the valve's capacity to allow fluid flow; a higher Cv value denotes a more efficient valve with less resistance, enhancing the overall system performance.

Another important metric is the temperature rating of the ebonite lining, as it directly impacts the valve's performance in extreme conditions. The material's ability to resist chemical erosion and physical wear is vital for maintaining integrity and function over time. Furthermore, evaluating the valve's operational characteristics, such as response time and control precision, ensures it meets the specific needs of the application. By keeping these performance metrics in mind, one can make an informed decision when selecting the ideal ebonite lined butterfly valve that ensures reliable operation and aligns with system requirements.

Ebonite lining is widely recognized in industrial applications for its unique ability to withstand harsh conditions. This type of lining is particularly effective in environments where abrasion, corrosion, and chemical exposure are persistent challenges. One common application is in the mining industry, where ebonite-lined butterfly valves facilitate the control of mineral slurries. These slurries often contain abrasive particles that can quickly wear down traditional valve materials, but ebonite’s tough surface helps prolong the lifespan of the valves, reducing maintenance costs and downtime.

Another critical application of ebonite lining is in the chemical processing sector. In this industry, valves encounter corrosive substances at varying temperatures and pressures. Ebonite’s excellent chemical resistance allows it to serve as an effective barrier, minimizing the erosion of the valve and ensuring that process integrity is maintained. Moreover, ebonite-lined butterfly valves are often preferred for their ability to provide a tight seal, which is essential for preventing leaks and ensuring safety in operations involving volatile chemicals. This combination of durability and reliability makes ebonite lining an ideal choice for industrial settings aiming for optimal performance.

| Application Area | Ebonite Lining Benefit | Ideal Operating Conditions | Temperature Range (°C) | Pressure Range (Bar) |

|---|---|---|---|---|

| Chemical Processing | Corrosion Resistance | Acidic and Alkali Environments | -20 to 90 | 0-10 |

| Water Treatment | Abrasive Resistance | High Flow Conditions | 0 to 70 | 0-5 |

| Oil and Gas | Low Permeability | High Viscosity Fluids | -30 to 120 | 0-50 |

| Pharmaceuticals | Hygienic Properties | Sterile Conditions | 10 to 80 | 1-5 |

Maintaining ebonite lining butterfly valves is essential for ensuring their performance and longevity. Regular upkeep can greatly reduce the likelihood of malfunctions and extend the lifespan of the valves. One key aspect of maintenance is routine inspection. Checking for signs of wear, corrosion, or leakage should be done periodically. If any signs of damage are found, timely repairs or replacements are critical to prevent further issues.

Another crucial tip is to keep the valve clean. Debris and dirt can accumulate in and around the valve, leading to operational inefficiencies. Utilizing a soft brush or cloth to gently clean both the exterior and interior surfaces can help. Additionally, lubricating moving parts minimizes friction, which can wear down components over time. Make sure to use the appropriate lubricant compatible with the ebonite lining to avoid chemical reactions that could degrade the material.

Finally, it is helpful to familiarize yourself with the operational limits of the butterfly valve, including pressure and temperature ratings. This knowledge ensures the valve is not subjected to conditions beyond its design specifications, preventing premature failure. By following these maintenance tips, operators can optimize the performance and reliability of ebonite lining butterfly valves for various applications.