Leave Your Message

When selecting the right butterfly valve for your project needs, it’s essential to understand both the technical specifications and operational requirements that different applications demand. In recent years, the global butterfly valve market has experienced substantial growth, projected to reach USD 7.6 billion by 2026, according to a report by Research and Markets. This rapid expansion highlights the increasing reliance on butterfly valves in various industries, including water treatment, oil and gas, and HVAC systems.

Industry experts emphasize the importance of making informed choices in this area. John Smith, a recognized authority in valve technology, stated, "Choosing the right butterfly valve is crucial for ensuring operational efficiency and reliability in any fluid system." The decision-making process involves evaluating factors such as valve size, material compatibility, and pressure ratings. Each of these elements can significantly influence the performance and lifespan of the valve, making it imperative for engineers and project managers to carefully assess their specific requirements before finalizing their selection. By understanding the nuances of butterfly valve options, stakeholders can optimize their systems for better performance and cost-effectiveness.

Butterfly valves are essential components in various industrial applications, serving as a simple yet effective means of controlling fluid flow. At its core, a butterfly valve consists of a circular disc positioned in the center of a pipe. This disc acts as a barrier to fluid flow, rotating on a shaft that allows for quick opening and closing. The design enables efficient operation with minimal pressure drop, making butterfly valves ideal for applications where space and weight are considerations.

The performance of a butterfly valve is influenced by several factors, including the material of construction, the type of actuator used, and the valve’s pressure rating. Common materials for butterfly valves include metal, plastic, and rubber, each suited for different environments and fluid types. Understanding these basics leads to better selection for specific project needs, ensuring that the valve will operate effectively under the desired conditions. Additionally, considerations such as the valve's size and the anticipated flow rate must also be taken into account to achieve optimal performance and longevity in the specified application.

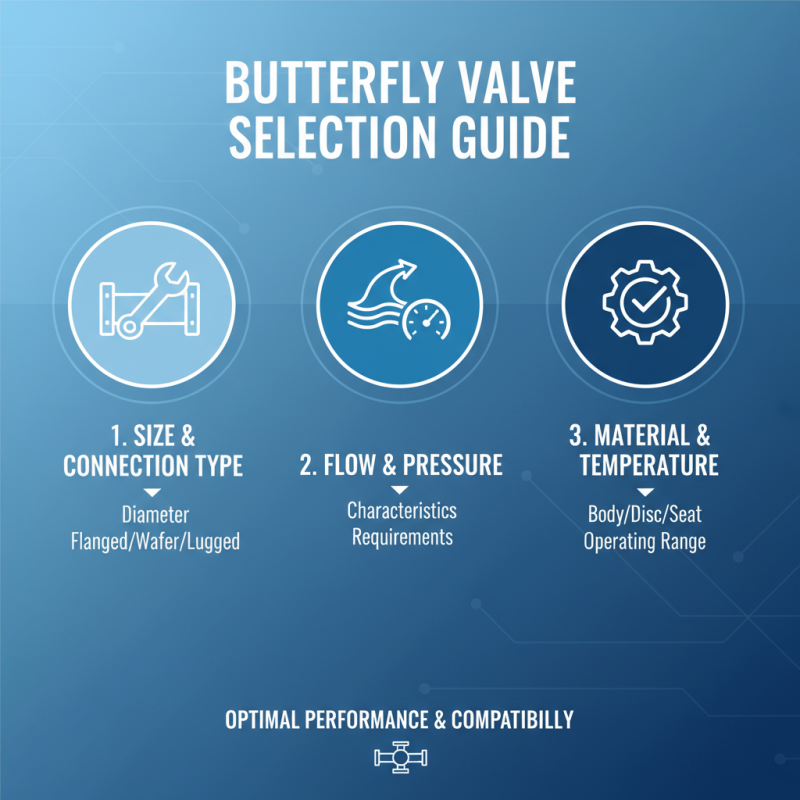

When selecting a butterfly valve for your project, several key factors should be carefully considered to ensure optimal performance and compatibility. First and foremost, the valve's size and connection type must align with the specifications of your piping system. Understanding the flow characteristics and pressure requirements of the application will significantly influence the choice of valve diameter. It's also essential to evaluate the connection type, whether it's flanged, wafer, or lugged, as this will affect the installation process and the overall integrity of the system.

Another critical consideration is the material of the valve. Butterfly valves can be constructed from various materials including stainless steel, cast iron, and plastic, each offering distinct advantages, such as corrosion resistance and durability under high temperatures. Assessing the service conditions, including the nature of the fluid being controlled—be it water, chemicals, or gases—will help you select a valve with the appropriate material properties. Additionally, the sealing mechanism is vital in preventing leakage, and options may vary from rubber-lined to metal-seated designs, depending on the specific application requirements. Overall, thorough analysis of these factors will lead to a well-informed decision, ensuring the chosen butterfly valve meets the operational demands of your project.

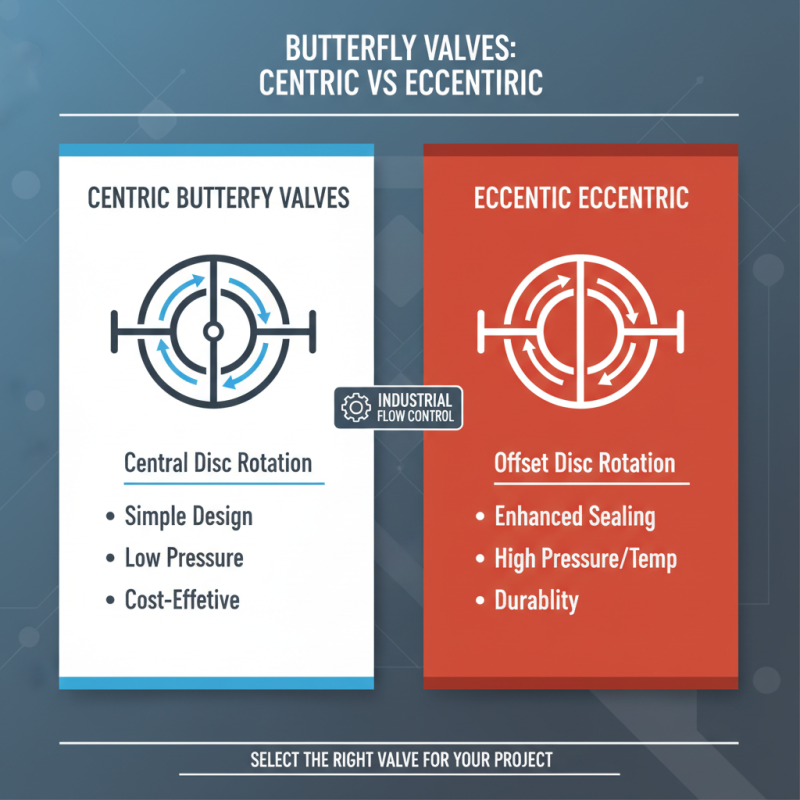

Butterfly valves are essential components in many industrial applications, designed to control the flow of liquids and gases with precision. Understanding the different types of butterfly valves is crucial for selecting the appropriate valve for specific project needs. The two primary types are centric and eccentric butterfly valves. Centric valves feature a disc that rotates around a center axis, making them suitable for low-pressure applications due to their simple design and cost-effectiveness. Eccentric valves, on the other hand, have a disc that is offset from the center, allowing for better sealing capabilities and the ability to handle higher pressures and temperatures.

Another important classification is the difference between wafer-style and lug-style butterfly valves. Wafer-style valves are installed between two flanges and are typically lighter and more compact, making them ideal for situations with limited space. Conversely, lug-style valves have threaded holes, allowing for bolting directly to the pipeline, which provides added stability and can be beneficial for applications requiring frequent maintenance or replacement. By understanding these types and their applications, you can make more informed decisions when it comes to selecting the right butterfly valve for your specific project requirements.

When selecting a butterfly valve, the choice of materials is crucial for ensuring durability and optimal performance in various applications. According to the Valve Manufacturing Market Report by Industry Research, the selection of the right materials can significantly impact valve lifespan, with studies indicating that valves made from high-quality materials can exhibit a 30% increase in operational longevity compared to those made from inferior alternatives. This underscores the importance of understanding the environmental and operational demands that your project may impose on the valve.

Common materials used in butterfly valves include stainless steel, cast iron, and PVC, each offering unique advantages.

Stainless steel valves, for instance, are renowned for their corrosion resistance and are ideal for applications involving harsh chemicals or high temperatures. They can withstand pressures exceeding 150 psi, showcasing their resilience in demanding conditions. On the other hand, for systems where weight reduction is critical, such as in aerospace applications, PVC valves may be preferred for their lightweight properties; however, they are generally not suitable for high-temperature environments. Research also highlights that selecting the appropriate valve material can reduce maintenance costs by up to 25%, demonstrating that informed material choices can lead to significant long-term savings and project efficiency.

When selecting a butterfly valve, understanding the installation and maintenance requirements is crucial for ensuring optimal performance and longevity. Proper installation is essential, as improper fitting can lead to leaks, inefficient operation, and system failures. According to industry reports, nearly 30% of valve failures are attributed to installation errors. It is recommended that professionals follow guidelines from organizations such as the American National Standards Institute (ANSI) to ensure alignment, support, and sealing of the valve, which contributes significantly to its efficiency.

In terms of maintenance, butterfly valves generally require less upkeep compared to other valve types, but they still need regular inspections to prevent issues. Routine checks for wear on seals and the condition of the actuator can extend the lifespan of the valve significantly. Data from the International Society of Automation (ISA) indicates that routine maintenance can improve valve reliability by up to 40%. Simple practices, such as monitoring the valve position and checking for unusual noises during operation, can help identify potential problems before they lead to costly repairs or replacements. Implementing these measures will ensure that the valve operates efficiently and effectively throughout its service life.

This chart illustrates the flow capacity in gallons per minute (GPM) for various sizes of butterfly valves. Understanding these metrics can help you choose the right valve for your project needs.