Leave Your Message

Choosing the right Desalination Butterfly Valve is crucial for any water treatment system. These valves play an essential role in regulating flow and ensuring optimal performance. They are designed to withstand harsh conditions, making them vital for desalination processes.

Different factors must be considered when selecting a Desalination Butterfly Valve. Valve size, material, and pressure ratings directly impact efficiency and durability. Many overlook these details, yet they are vital for a successful operation. Inadequate choices can lead to premature failures.

Furthermore, working with suppliers can be beneficial. They provide insights on product specifications and compatibility. However, not all suppliers offer reliable information. It’s essential to conduct thorough research and evaluate options carefully. Understanding your system's unique requirements will pave the way for better outcomes.

Choosing the right desalination butterfly valve is crucial for system efficiency. Several factors play a role in this decision. First, consider the valve material. Corrosion resistance is essential due to saline exposure. Common materials include stainless steel and plastic. Each option has its advantages, but they also come with limitations. For instance, while plastic is lightweight, it may not withstand high pressure.

Next, valve size is significant. A poorly sized valve can lead to flow issues. Oversized valves might result in turbulence. This can reduce the system's overall efficiency. Conversely, undersized valves can cause excessive pressure drops. It’s vital to consult flow charts and system specifications for precise calculations.

Additionally, pay attention to the valve design. Some designs facilitate easier maintenance. Maintenance can be a hassle if the design isn't user-friendly. Accessibility to the valve during operation matters. Sometimes, cumbersome designs create challenges. Reflect on your system's maintenance needs before deciding. This careful consideration helps in optimizing performance and extending component lifespan.

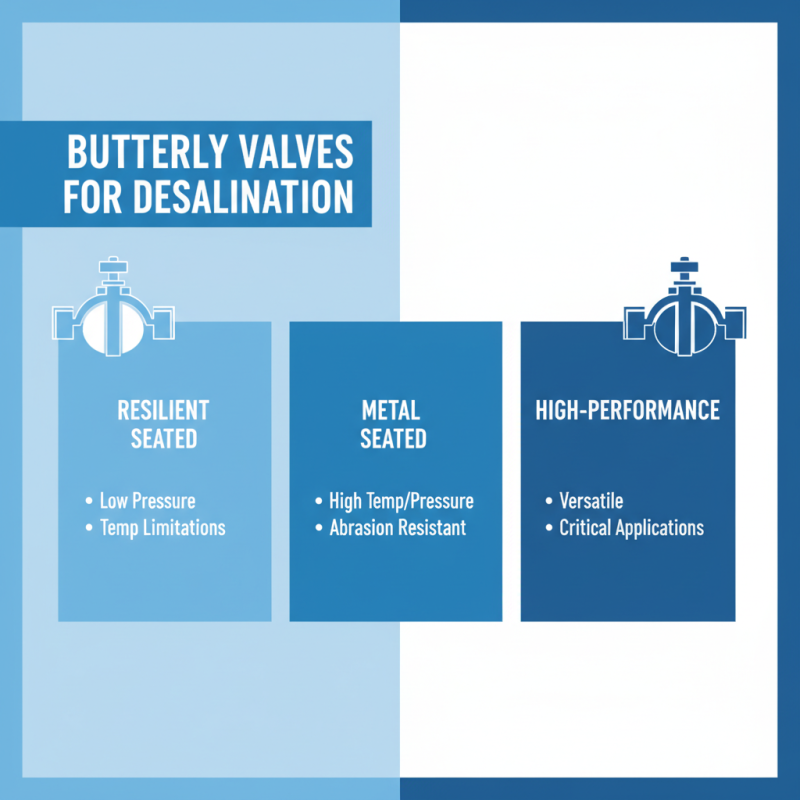

When choosing butterfly valves for desalination, consider the specific types suitable for your application. The three main types are resilient seated, metal seated, and high-performance butterfly valves. Each has its unique advantages and drawbacks. Resilient seated valves are great for low-pressure applications. However, they may not handle extreme temperatures well.

Metal seated valves are more durable and can tolerate higher pressures. Yet, they may require more maintenance over time. High-performance valves offer flexibility and can adapt to various conditions, but they might come with a higher cost.

Tips: Always assess the composition of the fluids. Saltwater can be corrosive. Ensure your valve material is resistant. Regular maintenance is crucial. Check for wear and tear. Adaptation is key in this ever-changing environment. Make informed choices, but remember that even the best systems may face challenges. Don’t overlook the importance of testing under actual conditions.

When selecting a butterfly valve for desalination systems, material choice is crucial. The harsh environment demands high durability and corrosion resistance. Common materials include stainless steel and various plastics. Each material has pros and cons, depending on the specific application. It's important to consider the salinity level and temperature range of water being processed.

In some cases, even robust materials can fail. For example, stainless steel may corrode in certain conditions, despite its reputation. Plastic options may not withstand extreme temperatures. You may need to conduct tests to ensure longevity. Evaluating real performance data can be more beneficial than relying solely on specifications.

A good design also emphasizes the joining methods used. Flange connections can be susceptible to leaks if not installed properly. The chosen material should align with the expected pressure and fluid dynamics. Seek options that allow for easy maintenance and inspection. Over time, even the best materials may face wear. Understanding wear patterns can guide future selections. Continual assessment of valve performance is key to operational efficiency.

When selecting a desalination butterfly valve, proper sizing and flow requirements are critical. An undersized valve can lead to flow restriction. This may affect the system's efficiency. Conversely, an oversized valve can cause turbulence and excessive wear. Both scenarios create operational problems that compromise performance.

Determining flow rates is the first step. It's essential to understand the maximum and minimum flow your system will experience. Measure the pressure drop across the valve as well. This data helps in selecting a valve that optimizes flow characteristics. Dealing with fluctuating pressure and flow can be challenging. Engineers need to reassess the system regularly to ensure optimal performance.

Material choice should not be overlooked. Corrosion resistance is vital in desalination systems. Saltwater can degrade certain materials quickly. Consider factors like temperature and the fluid's chemical composition. The right combination leads to longer service life and fewer maintenance needs. It's a balance between durability and performance that requires careful thought and adjustment. Operators should constantly revisit their choices to address unexpected challenges.

| Valve Size (inches) | Pipeline Diameter (mm) | Flow Rate (m³/h) | Pressure Drop (bar) | Material Type | Temperature Range (°C) |

|---|---|---|---|---|---|

| 4 | 100 | 25 | 1.2 | PVC | 5-40 |

| 6 | 150 | 45 | 1.5 | Stainless Steel | 0-80 |

| 8 | 200 | 80 | 2.0 | Ductile Iron | 0-90 |

| 10 | 250 | 100 | 2.5 | Brass | 10-80 |

When selecting a desalination butterfly valve, maintenance and lifespan are crucial factors. Desalination systems operate under high pressure and harsh conditions. Regular maintenance can significantly enhance valve performance. According to a 2022 industry report, improperly maintained valves can lead to a failure rate as high as 30%. This failure can cause system shutdowns, generating high operational costs.

Choosing the right materials for corrosion resistance is vital. Many valves encounter brine and seawater, which contain corrosive elements. A report by the International Desalination Association noted that valves made from duplex stainless steel could last up to 20 years with proper care. However, neglecting routine inspections can shorten this lifespan drastically. A missing grease fitting here or a cracked sealing surface there can lead to leaks or even catastrophic failures.

Monitoring the condition of valves is essential. Infrared thermography and ultrasonic testing have become standard methods for evaluating valve conditions. Without these tools, it's easy to overlook degradation signs. A recent study highlighted that 25% of maintenance issues go unnoticed due to inadequate monitoring practices. This can be a costly oversight for operators, emphasizing the need for a proactive approach to valve maintenance in desalination systems.