Leave Your Message

Choosing the right Double Flange Butterfly Valve is crucial for various industrial applications. According to a report by MarketsandMarkets, the global butterfly valve market is projected to reach USD 7.9 billion by 2025. This growth reflects an increasing demand for efficient flow control solutions in sectors like water treatment and oil & gas.

Understanding the key features of Double Flange Butterfly Valves is essential. A good valve enhances system performance and reduces maintenance costs. However, selecting the wrong valve can lead to leaks and system failures. These errors often arise from a lack of comprehensive understanding about the application's specific needs.

In many cases, users overlook critical specifications like temperature, pressure, and fluid type. This oversight may cause selection mistakes. Even experienced engineers sometimes underestimate the importance of accurate sizing. Ultimately, investing time in evaluating options can lead to better performance and reliability in fluid management systems and reduced long-term costs.

Double flange butterfly valves play a crucial role in various industrial applications. These valves regulate flow in pipelines efficiently. Industries such as water treatment, oil, and gas heavily utilize them. According to a report by MarketsandMarkets, the global butterfly valve market is expected to grow from USD 4.7 billion in 2022 to USD 6.3 billion by 2027. This growth reflects rising demand in multiple sectors.

When choosing a double flange butterfly valve, several factors matter. Size, pressure rating, and material are critical components. A well-chosen valve can prevent leaks and reduce downtime. However, some users overlook the impact of their choices. Using the wrong size or material can lead to premature failure. It’s vital to consult industry standards and guidelines, but even those can sometimes be vague or insufficient.

Another consideration is the application environment. Corrosive conditions require special materials. A study by ResearchAndMarkets indicates that the demand for corrosion-resistant valves has increased by 15% annually. Installing valves without proper assessment may lead to costly repairs or replacements. Understanding specific needs is essential. Make sure to analyze your system's requirements thoroughly before making a decision.

When selecting a double flange butterfly valve, several factors are crucial. The application environment matters greatly. Is it for water, oil, or chemical processes? Each medium has unique requirements. Take the temperature and pressure ratings into account. A valve rated for high pressure might not work well in low-pressure systems.

Material selection is another key aspect. Stainless steel offers great durability but can be costly. Plastic valves are lighter but may not hold up in harsh conditions. Even within these categories, variations exist. Checking the valve's resistance to corrosive substances is essential.

Don’t neglect the size and dimensions of the valve. It must fit the piping system perfectly. A valve that is too large or too small can lead to inefficiencies. Be cautious about the design features. Some models might look appealing but lack functionality. Always cross-check specifications with actual needs. A thoughtful selection can save money and time in the long run.

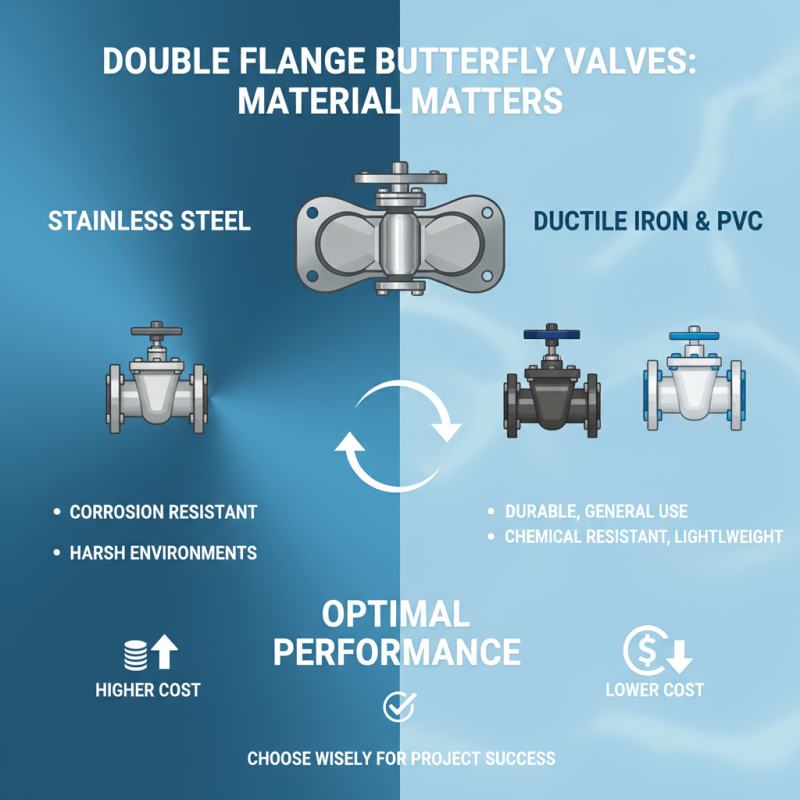

When selecting a double flange butterfly valve, material plays a crucial role in performance. Common materials include stainless steel, ductile iron, and PVC. Stainless steel valves offer excellent corrosion resistance. They are ideal for harsh environments. However, their higher cost can be a drawback for some projects.

Ductile iron is another popular choice. It provides strength and durability at a reasonable price. These valves perform well in water and wastewater applications. However, they may not handle highly corrosive substances as effectively as stainless steel. PVC valves are lightweight and easy to install. They are suitable for less demanding environments but can lack durability over time.

Choosing the right material requires careful consideration. Think about the operational environment and specific application needs. Material choice impacts valve longevity and maintenance requirements. Overlooking these factors might lead to premature failures. It’s essential to weigh the pros and cons of each material before making a decision.

When selecting a double flange butterfly valve, understanding size and pressure ratings is crucial. The right size ensures optimal flow rate and reduces energy loss. According to industry reports, over 30% of inefficiencies in fluid systems stem from improper valve sizing. A valve that is too small restricts flow, while an oversized valve may fail to control it effectively.

Pressure ratings are equally important. They determine the maximum pressure a valve can handle safely. Failing to match these ratings with system requirements can lead to catastrophic failures. A recent survey indicated that nearly 25% of valve failures in industrial applications occurred due to exceeding pressure limits.

Tips: Always consult the manufacturer's specifications to confirm that the valve meets the pressure requirements of your system. Consider using a pressure gauge during testing phases to avoid oversights. Also, inspect the valve periodically. Regular maintenance can prevent unexpected failures. Remember, a little diligence pays off in the long run!

| Valve Size (inches) | Pressure Rating (PSI) | Material | Temperature Rating (°F) | End Connection Type |

|---|---|---|---|---|

| 2 | 150 | Cast Iron | -20 to 200 | Flanged |

| 3 | 150 | Ductile Iron | -20 to 250 | Flanged |

| 4 | 150 | Stainless Steel | -20 to 300 | Flanged |

| 6 | 300 | Cast Iron | -20 to 200 | Flanged |

| 8 | 150 | Ductile Iron | -20 to 250 | Flanged |

Proper maintenance and installation of double flange butterfly valves are crucial for optimal performance. Begin by checking the valve's seating and seals. Regular inspections will help you identify any wear early. Don't forget to lubricate moving parts as needed. Often, users overlook this step, leading to premature failure.

Installation requires careful attention. Align the valve properly with the pipeline. Misalignment can cause leaks or operational issues. Use appropriate gaskets and bolts to secure the valve. Ensure they are not overtightened; this can damage the valve. Regularly review your installation checklist to avoid missing any details. Remember, even minor errors can lead to significant problems over time.

After installation, monitor performance closely. Pay attention to any unusual sounds or leaks. Address these issues promptly to prevent larger failures. Keeping a maintenance log helps track performance and spot trends. However, many forget this step. It's easy to overlook. Regular reminders can help establish a routine. Always aim for a proactive approach to valve care.