Leave Your Message

In various industrial applications, the selection of the right valves can significantly influence the efficiency and safety of fluid management systems. Among the many types of valves available, the Rubber Seat Butterfly Valve has garnered considerable attention due to its versatility and reliability in controlling flow. According to a report by MarketsandMarkets, the global valve market is projected to reach USD 85.7 billion by 2025, with a notable increase in demand for butterfly valves attributed to their lightweight design and ease of operation.

Rubber Seat Butterfly Valves, in particular, offer advantages such as enhanced sealing capabilities and resistance to corrosion, making them suitable for a variety of media, including water, oil, and gas. The rise of industries like water treatment, oil and gas, and power generation is driving the need for effective flow control solutions, which further underscores the importance of choosing the right valve for specific applications. With an increasing focus on cost-efficiency and durability, understanding the nuances of Rubber Seat Butterfly Valves will empower engineers and procurement specialists to make informed decisions that align with operational goals and environmental standards.

Rubber seat butterfly valves are essential components in many industrial applications due to their lightweight design, ease of use, and excellent sealing performance. These valves are primarily used for regulating flow in pipes, providing a tight seal to prevent any leakage when closed. According to industry reports, the global butterfly valve market is expected to reach approximately $7.5 billion by 2025, highlighting the growing importance of effective flow control solutions across various sectors, including water treatment, oil and gas, and chemical processing. Rubber seat butterfly valves are particularly favored in systems where the fluid's media can be corrosive or abrasive, as the rubber seat helps to minimize wear and extend the product life.

When considering the right rubber seat butterfly valve for your application, it's crucial to evaluate the specific requirements of your system. Factors such as operating pressure, temperature, and the type of fluid being conveyed should be thoroughly assessed. For instance, high-temperature applications may require valves made from enhanced thermal materials or rubber compounds that can withstand such conditions. It's also worth noting that periodic maintenance and inspection are essential to ensure optimal valve performance and longevity in demanding environments.

**Tip:** Always consult with a technical expert or draw insights from comprehensive market studies to determine the best specifications for your butterfly valves. Additionally, consider the ease of installation and the availability of replacement parts when making your decision. Doing so can help prevent costly downtime and enhance the efficiency of your system.

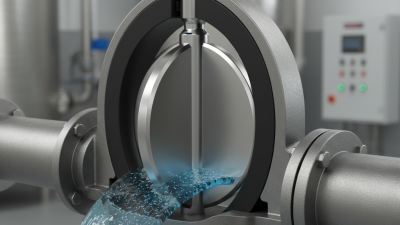

When selecting a rubber seat butterfly valve for your applications, several critical factors should be taken into account to ensure optimal performance and longevity. First and foremost, consider the operating conditions such as pressure, temperature, and the type of fluid being handled. Different rubber compounds can withstand various levels of pressure and temperature, so it's essential to choose a material that aligns with your specific application requirements. For instance, some rubber materials are more resistant to certain chemicals, while others may degrade faster under extreme temperatures.

Additionally, the valve’s size and connection type are important factors to evaluate. The size should match the flow requirements of your system, while ensuring compatibility with existing piping. Incorrect sizing can lead to inefficiencies and potential system failures. The connection type—whether flanged, threaded, or wafer—also plays a crucial role in ease of installation and maintenance. Ensuring a proper fit will not only reduce the risk of leaks but will also enhance the overall reliability of the system.

Lastly, consider the valve’s design features, such as the ease of operation and the reliability of the sealing mechanism. Look for valves that offer smooth operation with minimal torque and have a robust sealing design to prevent leaks. A good rubber seat butterfly valve should provide consistent sealing performance over time, which is vital for maintaining system integrity and minimizing maintenance costs.

Material compatibility is a crucial factor when selecting a rubber seat butterfly valve, as it significantly impacts the overall performance and durability of the valve in various applications. Different media can cause degradation or failure of the materials used in the valve, leading to costly downtime or even catastrophic failures. According to the Valve Manufacturers Association (VMA), nearly 30% of valve failures are attributed to material incompatibility. This statistic emphasizes the importance of conducting a thorough compatibility analysis before making a selection.

Rubber seat materials, commonly used in butterfly valves, must withstand various chemical exposures, operating temperatures, and pressures. For instance, EPDM (Ethylene Propylene Diene Monomer) is known for its excellent resistance to heat and various chemicals, making it suitable for applications involving hot water and steam. On the other hand, NBR (Nitrile Butadiene Rubber) is favored for its superior resistance to oils and fuels but is less effective against oxidizing agents. Reports from the American Society of Mechanical Engineers (ASME) suggest that misalignment of material selection with application requirements can reduce valve lifespan by up to 50%, highlighting the critical nature of correct material evaluation.

Incorporating comprehensive material compatibility assessments into your decision-making process can lead to improved valve reliability and efficiency. For instance, the Industrial Valve Association recommends utilizing compatibility charts that outline the resistance of various rubber materials to specific chemicals and environmental conditions. By leveraging such resources, engineers can optimize their design choices, enhance operational longevity, and minimize maintenance costs, ultimately ensuring a more reliable valve performance in critical applications.

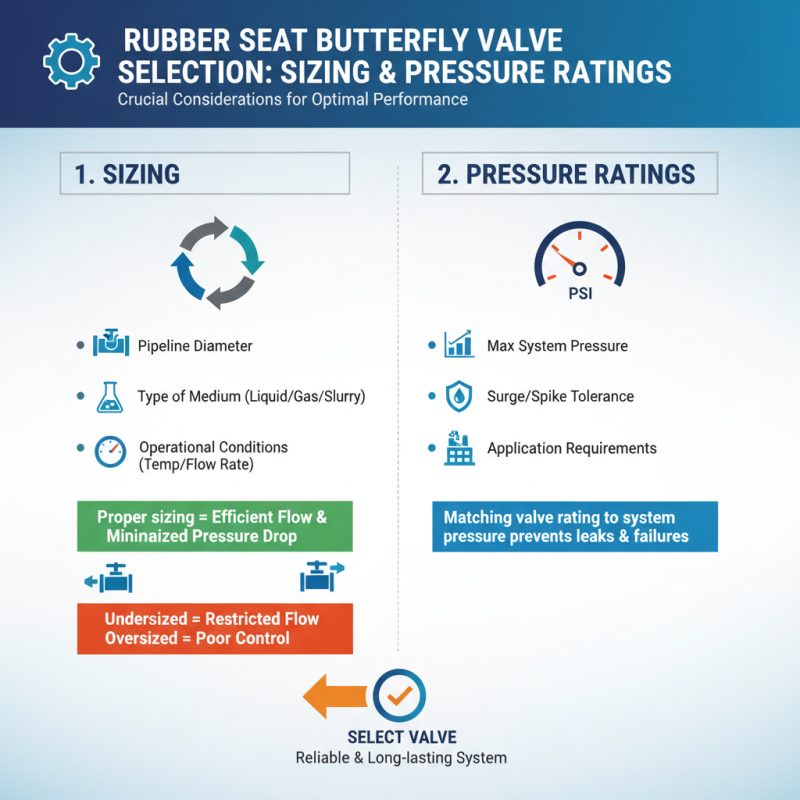

When selecting the right rubber seat butterfly valve for your applications, one of the most crucial considerations is understanding the sizing and pressure ratings. Proper valve sizing ensures that the system can handle the required flow rates without causing unnecessary pressure drops. It's essential to evaluate the pipeline diameter, the type of medium being transported, and the operational conditions to determine the appropriate valve size. An undersized valve can lead to restricted flow, while an oversized valve may not sufficiently control the flow, resulting in operational inefficiencies.

Pressure ratings play a vital role in selecting a valve that can withstand the demands of your specific application. Each valve is rated for a maximum pressure, which, if exceeded, can lead to valve failure and potential system damage. It's important to assess the operating pressure of your system and choose a valve that can handle at least the maximum expected pressure. Additionally, consider the environmental conditions, such as temperature and chemical exposure, as these factors can impact the valve's performance and longevity.

Tips: Always refer to the manufacturer’s specifications for both the sizing and pressure ratings of valves. Consulting with industry experts can provide valuable insights into the best practices for your specific application. Regular maintenance and inspection of the valve can also help ensure optimal performance and prevent unexpected failures during operation.

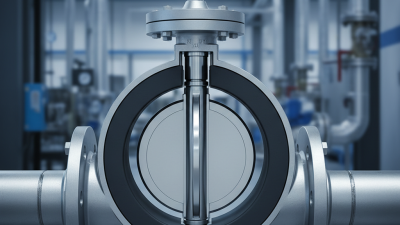

When selecting a rubber seat butterfly valve, it's crucial to consider maintenance and durability to ensure optimal performance in various applications. Maintenance plays a pivotal role in the lifespan of a valve. Regular inspection of the butterfly valve for signs of wear, such as cracking or swelling of the rubber seat, is essential. If a valve is used in a corrosive environment, an increased frequency of checks may be necessary to prevent leakage and ensure that the valve operates smoothly without hindrance. Establishing a routine maintenance schedule can significantly reduce downtime and extend the valve’s operational life.

Durability is another critical factor in valve selection, as the materials used in the valve components can influence how well it withstands harsh operating conditions. Rubber seats, for instance, should be chosen based on their resistance to temperature fluctuations, chemical exposure, and physical abrasion. A higher quality rubber material can provide enhanced resilience against aging and environmental degradation. By selecting a valve designed for durability, you will not only improve reliability but also minimize the likelihood of premature failures, leading to cost savings and improved efficiency in your operations.

| Valve Type | Size (inches) | Material | Temperature Range (°C) | Pressure Rating (PSI) | Maintenance Frequency | Expected Lifespan (years) |

|---|---|---|---|---|---|---|

| Standard Rubber Seat | 2 | EPDM | -10 to 80 | 150 | Annual | 10 |

| High-Performance Rubber Seat | 4 | NBR | -20 to 100 | 200 | Bi-annual | 15 |

| Chemical Resistance Rubber Seat | 6 | Silicone | -30 to 90 | 150 | Quarterly | 20 |