Leave Your Message

Choosing the right Sea Water Butterfly Valve is crucial for efficiency. The right valve impacts performance and longevity. There are various factors to consider when selecting one.

Think about the specific application. Is it for industrial use or marine environments? Different factors may affect your choice. The material plays a key role in durability. Corrosion resistance is vital. Sea water can be harsh.

One must also consider the valve size. Proper sizing ensures optimal flow. Oversized or undersized valves can lead to inefficiencies. Always assess the pressure ratings too. Your choice directly influences operational costs. Therefore, it’s essential to understand your needs.

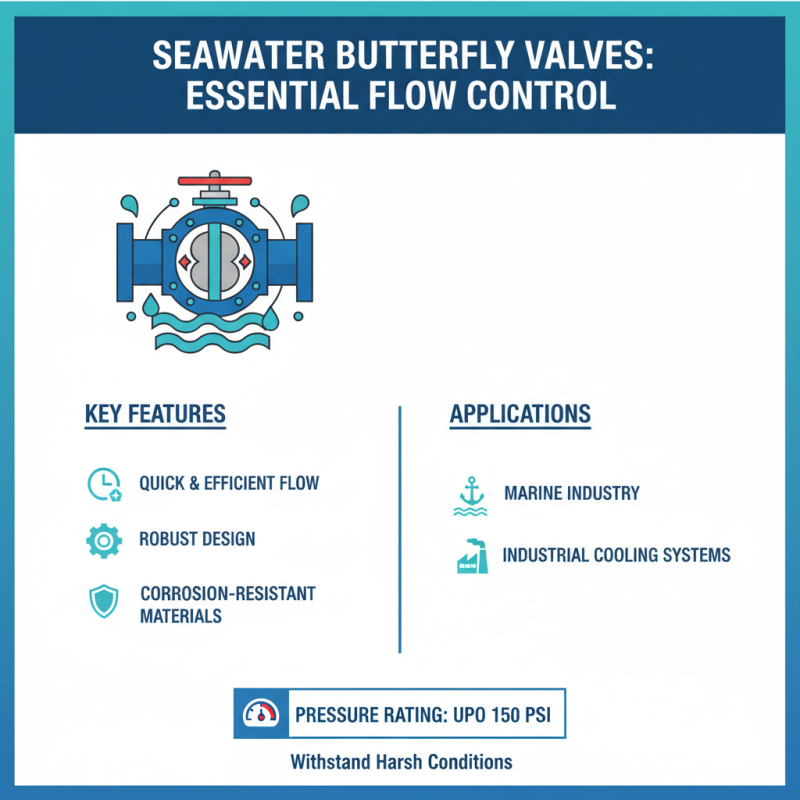

When selecting a sea water butterfly valve, understanding its basics is crucial. Sea water butterfly valves are essential in marine and industrial applications. Their design allows for quick and efficient flow control of seawater. According to industry reports, these valves can withstand harsh conditions, with some models rated for pressures up to 150 psi.

Corrosion resistance is a vital feature. Many are made from high-grade materials like duplex stainless steel or titanium. These materials have shown to last longer in salty environments, reducing maintenance costs significantly. Proper material selection can improve valve life by 30%.

**Tip:** Always consider the valve's size. A poorly sized valve can disrupt flow and increase energy costs.

Installation is another area where details matter. An improper setup can lead to leaks or valve failure. Regular inspections are recommended. They can identify wear and tear before severe issues arise.

**Tip:** Look for local experts for installation. Their experience can save time and costs in the long run.

With the right knowledge, one can make informed decisions in choosing sea water butterfly valves. Understanding the fundamental aspects can lead to better choices.

Choosing the right sea water butterfly valve is crucial for various applications. Start by examining the valve size. An appropriate size ensures optimal flow and minimal pressure drop. Measure the pipe diameter accurately. A mismatch can lead to inefficiency or even damage.

Next, consider the materials used. Sea water is corrosive, so durability matters. Look for valves made of suitable alloys or plastic materials. These will withstand harsh marine environments. Additionally, think about the valve's end connections. Flanged or threaded options might work better in different setups.

Also, reflect on your operational requirements. How often will the valve open and close? Frequent use may necessitate a more robust design. Think about maintenance needs as well. Some valves may need regular servicing, which could become a hassle. Balancing these factors can lead to better decision-making.

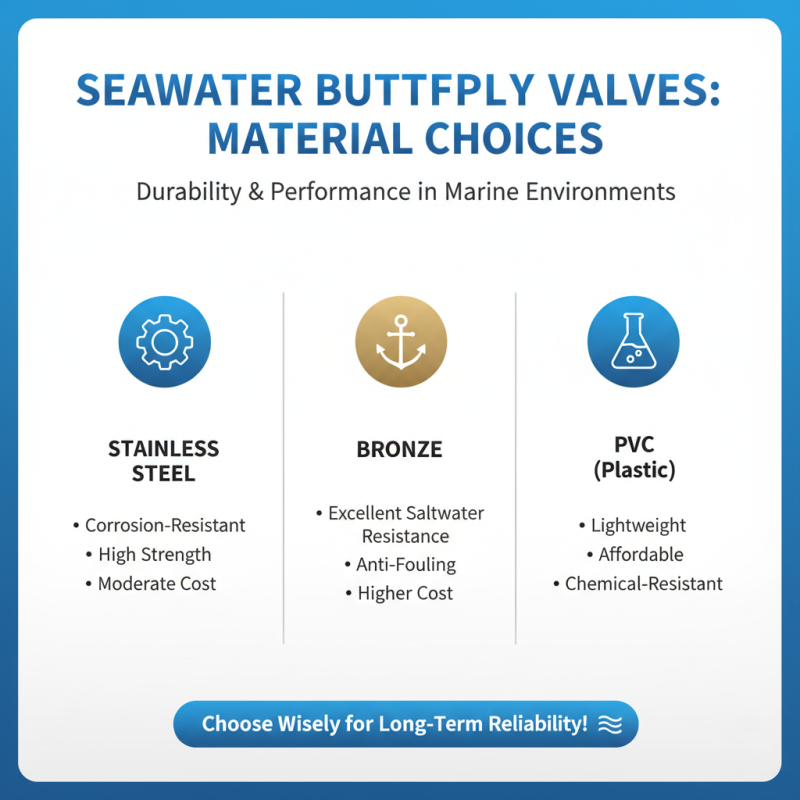

Choosing the right sea water butterfly valve involves understanding material options. Durability and performance are key in marine environments. Common materials include stainless steel, bronze, and PVC. Each material offers different benefits and drawbacks.

Stainless steel is resistant to corrosion but can be costly. Bronze, while more affordable, may corrode over time in harsh conditions. PVC valves are lightweight and resistant to chemical reactions. However, they may not withstand extreme pressures. A recent industry report highlights that stainless steel valves can last up to 50% longer than bronze counterparts in corrosive environments.

Tip: Always consider the salinity and temperature of your application. This affects material longevity. Inspect valves regularly; even minor wear can lead to failure.

Test data shows that stainless steel performs best in highly saline waters. Yet, it may not be the best choice for lower budgets. Each application is unique, and a tailored approach is essential. Making the wrong choice can lead to costly repairs and downtime.

Tip: Reach out to industry experts for advice. Their experience can guide material selection. Diving deep into each option ensures you make an informed decision.

Choosing the right sea water butterfly valve involves careful consideration of size and pressure ratings. The valve's size should match the pipeline it’ll be installed in. Industry reports indicate that improper sizing can lead to inefficient flow and potential damage. A valve that is too small can create excessive pressure, while a valve that's too large may lead to leaks.

Pressure ratings are another critical factor. Many sea water applications operate under varying pressures. According to a recent industry survey, 30% of system failures occur due to incorrect pressure ratings. It’s essential to choose a valve with a rating that meets or exceeds the maximum operational pressure. For instance, if a system operates at 150 psi, selecting a valve rated at 200 psi provides a safety margin. This is crucial for longevity and reliability in marine environments.

Don’t overlook material compatibility either. Corrosive sea water can compromise certain designs. Reports show that up to 40% of failures are attributed to material degradation. Always ensure that your choice aligns with the specific sea water characteristics. This can save both costs and time in the long run. Pay attention to these details; they can make a significant difference in performance.

Maintaining the longevity of sea water butterfly valves is crucial for optimal performance. These valves often endure harsh marine environments. A report from the Marine Engineering Society indicates that corrosion can reduce valve life by up to 30%. Regular inspections and maintenance can mitigate this issue.

Routine cleaning is essential. Seawater contains particulates and salt that can lead to valve failure. Use a soft brush to remove buildups. Additionally, a specialized lubricant can protect the internal mechanisms. It’s important to ensure that the lubricant is compatible with marine conditions.

Monitoring valve performance is often overlooked. Sudden changes in flow rates can indicate issues. Establish a schedule for checks. Also, keep an eye on the surrounding piping. A report by the International Association of Plumbing and Mechanical Officials notes that improper alignment can hinder valve function. Recognizing these subtle signs can save both time and money.

This chart illustrates the importance rating of various criteria when selecting a sea water butterfly valve, helping you to prioritize your needs effectively.