Leave Your Message

In the world of industrial applications, selecting the right components is crucial for efficiency and reliability. Among these key components, the Rubberlined Butterfly Valve stands out due to its versatility in handling various fluids while providing excellent sealing properties. According to industry expert John Smith, "Choosing the right Rubberlined Butterfly Valve is essential for ensuring optimal performance and longevity in your system." This statement underscores the importance of careful consideration when it comes to selecting the appropriate valve for specific operational needs.

Rubberlined Butterfly Valves are designed to minimize leakage and withstand corrosive environments, making them ideal for a range of applications including water treatment, chemical processing, and HVAC systems. Understanding the specific requirements of your application, such as pressure, temperature, and the type of fluid being conveyed, is vital to making an informed decision. The intricacies of each setting can have profound impacts on the valve’s performance, safety, and maintenance cost.

As we delve deeper into the considerations for choosing a Rubberlined Butterfly Valve, it becomes clear that thorough research and expert guidance are invaluable. By addressing the nuances of material selection, size, and operational parameters, one can ensure that the chosen valve not only meets performance expectations but also enhances the overall efficiency of the system.

Rubberlined butterfly valves are versatile components commonly used in various industrial applications. Their design allows for efficient flow control in systems handling slurries, corrosive chemicals, and other challenging media. The rubber lining acts as a protective barrier, preventing corrosion and wear, which extends the lifespan of the valve. Understanding the specific requirements of your application will help in selecting the right valve, ensuring optimal performance and reliability.

When choosing a rubberlined butterfly valve, consider factors such as pressure ratings, temperature limits, and the nature of the media being transported. A properly selected valve can significantly impact your system's efficiency and operational costs. Additionally, take into account the valve’s size and configuration based on the pipeline dimensions and operational requirements.

**Tips:**

1. Always verify the compatibility of the rubber lining material with the media to prevent chemical reactions that could damage the valve.

2. Regular maintenance and inspection of the valve can help identify wear and tear early, ensuring that it continues to function effectively over time.

3. Seeking advice from a fluid control expert can provide valuable insights into choosing the right valve for your specific needs.

| Dimension | Value | Application |

|---|---|---|

| Diameter | 2" - 48" | Water Treatment |

| Pressure Rating | 150 PSI | Chemical Processing |

| Temperature Range | -20°F to 180°F | Food & Beverage |

| Material | EPDM, Nitrile | Industrial Liquid Transport |

| End Connection Type | Flanged, Wafer | HVAC Systems |

When selecting the appropriate rubberlined butterfly valve for your application, several key considerations regarding

size and type come into play. First and foremost, it is essential to assess the requirements of your system,

including fluid characteristics, pressure, and temperature. Understanding the flow capacity and the specific

conditions under which the valve will operate will help determine the right valve size. This ensures that the valve can handle the intended flow rate without

excessive pressure loss or valve failure, maintaining overall system efficiency.

In addition to the size, the type of rubber lining plays a critical role in valve performance. Different types of elastomers

offer varying levels of resistance to chemicals, abrasion, and temperature fluctuations. It is crucial to match the rubber lining with the nature of the materials

being handled to prevent compromised integrity and potential leaks. Furthermore, consider the installation requirements and whether the valve will be used in a

manual or automated system, as this can influence the choice of valve type. Taking these factors into consideration will lead

to a more informed decision, ultimately enhancing the reliability and longevity of your application.

When selecting a rubber-lined butterfly valve, material compatibility is a crucial consideration that can significantly enhance the performance and longevity of the valve in various applications. The rubber lining typically serves as a barrier against corrosion, abrasion, and chemical attack. According to a report by the Valve Manufacturers Association, improper material selection accounts for up to 30% of premature valve failures in industrial settings. Therefore, understanding the specific environmental conditions and fluid characteristics is essential in choosing a valve that will withstand the operational demands.

To ensure optimal performance, it is critical to assess the compatibility of the rubber lining materials with the fluids being handled. For instance, EPDM rubber is well-suited for applications involving water and steam, while nitrile rubber is better for petroleum-based products. A study conducted by the American Society of Mechanical Engineers revealed that valves made with compatible materials can have service lives increased by up to 50%. Therefore, engineers should conduct thorough compatibility testing, considering factors such as temperature, pressure, and chemical exposure, to avoid costly operational disruptions and safety hazards.

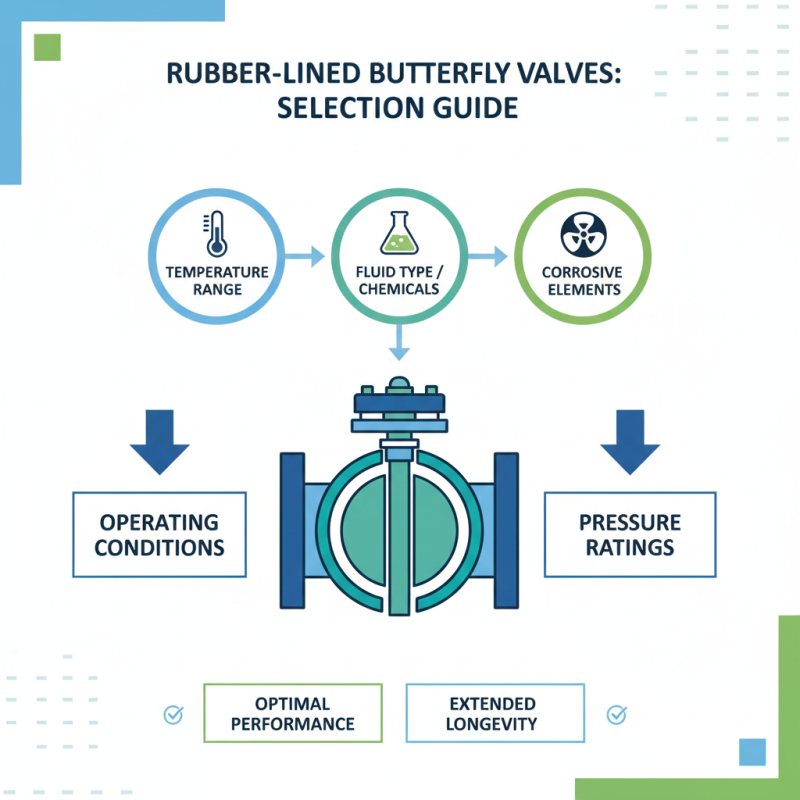

When selecting a rubberlined butterfly valve, understanding the operating conditions and pressure ratings is crucial for ensuring optimal performance and longevity. Firstly, evaluate the specific environment where the valve will be installed. This includes the temperature range, the type of fluid being handled, and any potential corrosive elements present. Rubber linings can vary significantly in their resistance to chemicals and thermal conditions, so matching the lining material with the operating environment is essential to avoid premature wear or failure.

Pressure ratings are another critical aspect to consider. Different applications may operate under varying pressure conditions, and it’s important that the selected valve can withstand these pressures without compromising safety or functionality. For instance, assess the maximum and minimum pressure levels the valve will encounter during operation. Additionally, consider factors such as pressure fluctuations and surge pressures, which can affect the valve's performance. Ensuring that the rubberlined butterfly valve's pressure rating exceeds the maximum expected operating pressure will enhance reliability and extend the valve's service life.

When selecting a rubberlined butterfly valve, the maintenance and reliability factors play a crucial role in ensuring optimal performance and longevity. A well-maintained valve minimizes the risk of unexpected failures that could lead to operational downtimes. Regular inspection and servicing are essential aspects of valve maintenance, as they help identify potential wear and tear on rubber linings, sealing surfaces, and actuators. To enhance reliability, it is advisable to establish a maintenance schedule that aligns with the specific operating conditions of the application, such as temperature fluctuations and exposure to corrosive substances.

Moreover, the choice of materials and the design of the valve impact its maintenance needs and overall reliability. Opting for high-quality rubber linings can significantly increase resistance to chemicals and abrasion, thereby reducing the frequency of replacements. It is also advisable to consider valves that allow for easy access to internal components for cleaning and repair. In addition, investing in valves that are equipped with features such as blow-off ports can facilitate the removal of debris that might hamper valve function, ultimately contributing to a more reliable and efficient system. Understanding these factors is vital for choosing the right rubberlined butterfly valve tailored to your application’s demands.