Leave Your Message

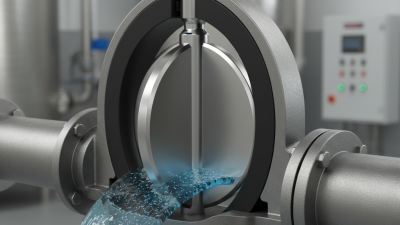

When selecting the right Pn25 Butterfly Valve for your application, it's essential to navigate through various technical specifications and considerations to ensure optimal performance and efficiency. The Pn25 designation indicates the pressure rating of the valve, signifying its capability to handle pressure up to 25 bar. This makes it a versatile choice for a wide range of industries, including water treatment, chemical processing, and HVAC systems, where reliable flow control is crucial.

In this guide, we will explore key factors that determine the suitability of a Pn25 Butterfly Valve for your specific needs. Understanding the material options, size requirements, and operational conditions will help you make an informed decision. Additionally, the correct valve design and features, such as the type of seat and body construction, play a significant role in ensuring durability and longevity under varied working conditions. By carefully considering these elements, you can select a Pn25 Butterfly Valve that not only meets your application demands but also enhances overall system efficiency.

When selecting the right PN25 butterfly valve for your application, understanding the key features and specifications is paramount. PN25 valves are designed to operate under a maximum pressure of 25 bar, making them suitable for high-pressure systems commonly found in industrial applications such as water treatment, HVAC, and chemical processing. The construction materials, including stainless steel, ductile iron, and plastic, play a crucial role in the valve’s performance and durability. According to a report by the Valves and Actuators Market Analysis (2021), the growing demand in the oil and gas sector is expected to increase the adoption of high-performance PN25 valves, leading to a projected market growth rate of 5.1% over the next five years.

In addition to pressure rating, other specifications such as temperature limits, flow characteristics, and flange types are pivotal when choosing a PN25 butterfly valve. The material choice affects not only the valve's pressure tolerance but also its compatibility with various media. Industry studies indicate that up to 30% of valve failures are linked to improper material selection, highlighting the importance of aligning the valve characteristics with the specific requirements of the process fluid. Moreover, understanding the actuation methods—manual, electric, or pneumatic—can further enhance operational efficiency and safety standards in industrial applications. Properly selecting a PN25 butterfly valve that meets these criteria can significantly improve system reliability and reduce maintenance costs over time.

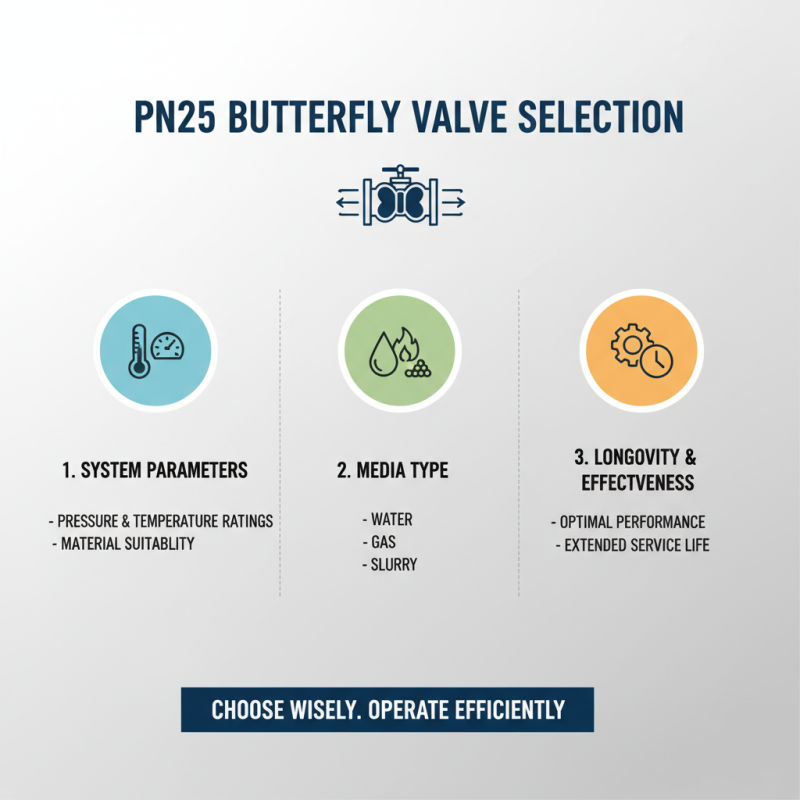

When selecting a PN25 butterfly valve for your application, the first step is to clearly identify your specific needs. Understanding the parameters of your system, such as pressure and temperature ratings, is crucial. These factors dictate the type of materials that will be suitable for the valve, ultimately influencing its longevity and effectiveness. Additionally, consider the type of media being controlled; whether it's water, gas, or slurry will significantly impact your valve choice.

**Tips:** Assess your process conditions meticulously. It's advisable to review the operational pressure, temperature fluctuations, and the chemical compatibility of the valve materials with the fluid in your system.

Selecting the proper valve size is equally important. This involves evaluating the flow requirements of your system to determine the appropriate diameter. An undersized valve can restrict flow and cause performance issues, while an oversized valve can lead to inefficiencies and wastage. Using hydraulic calculations can aid in making an informed decision.

**Tips:** Utilize flow rate calculators or consult with engineering estimates based on your application's specifications to ascertain the ideal valve size, ensuring optimal functionality and performance.

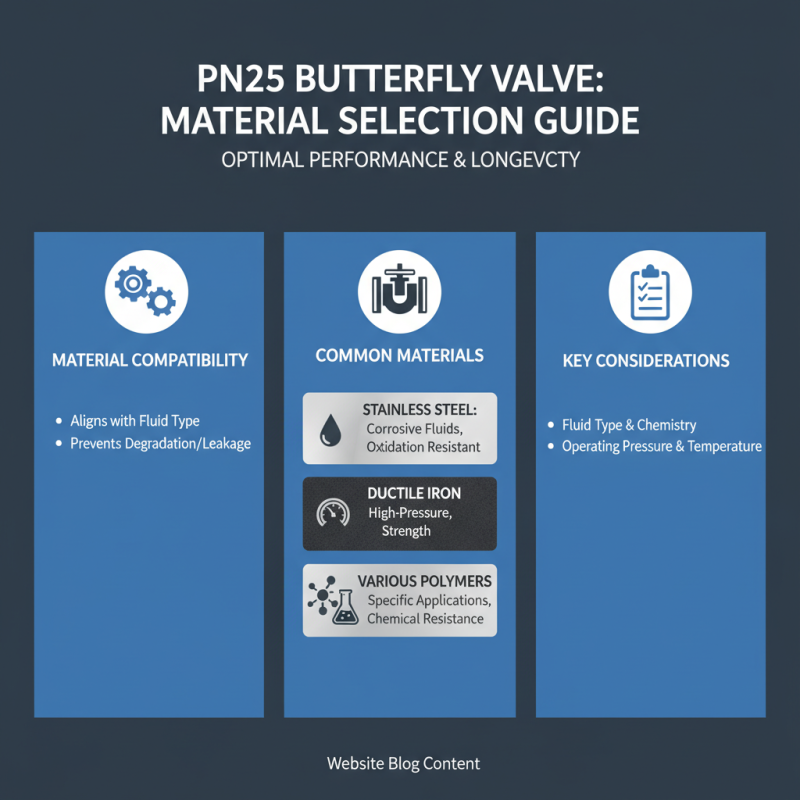

When selecting a PN25 butterfly valve, evaluating material compatibility is crucial to ensuring optimal performance and longevity. The construction materials of the valve must align with the fluid type and operating conditions to prevent chemical degradation, leakage, or failure. Common materials for PN25 butterfly valves include stainless steel, ductile iron, and various polymers, each having distinct properties suited for different applications. For instance, stainless steel is ideal for corrosive fluids due to its resistance to oxidation and aggressive chemicals, while ductile iron offers strength for high-pressure applications.

Additionally, temperature and pressure ratings play a significant role in material selection. High temperatures can lead to material softening or distortion, while extreme pressures may necessitate stronger or thicker materials to withstand the force. It is also essential to consider the environmental factors, such as the potential for exposure to UV radiation or extreme humidity, which could affect certain materials' durability over time. Ensuring compatibility between the valve materials and the operating environment will help in maintaining system integrity and reducing operational costs associated with premature valve replacement or repair.

When selecting a PN25 butterfly valve, installation considerations are crucial for ensuring optimal performance. Proper alignment of the valve with the pipeline is essential; misalignment can lead to increased wear and tear and reduced efficiency. According to a report by the Valve Manufacturers Association, improperly installed valves can increase operational costs by 20-30% over their lifetime due to frequent maintenance and reduced flow efficiency. Therefore, ensuring that the valve flanges are flat and parallel, and that the valves are centered within the pipeline, will help mitigate these issues.

Additionally, the choice of sealing materials plays a significant role in valve performance. The American Society of Mechanical Engineers recommends assessing the fluid characteristics and environmental conditions to select the appropriate seal that can withstand the temperature and pressure conditions of the application. For instance, using elastomers specifically designed for high-pressure systems can enhance durability and longevity. Studies indicate that valves installed with suitable seals can decrease leakage rates by up to 40%, thereby improving system efficiency and reliability. Proper installation practices, combined with informed material selection, are pivotal in maximizing the service life and functionality of PN25 butterfly valves in various industrial applications.

When it comes to maintaining Pn25 butterfly valves, regular inspection and servicing are crucial to ensuring their long-term performance and reliability. One key consideration is checking for any signs of wear or damage, which can often be detected during routine maintenance. Look for corrosion, cracks, or other physical deterioration that might compromise the valve's integrity. Keeping the valve clean and free from debris is essential, as contaminants can lead to improper sealing and operational failure.

Another critical tip is to regularly lubricate the valve components as recommended in the manufacturer's guidelines. Proper lubrication helps reduce friction and wear on moving parts, ensuring smooth operation. Additionally, monitoring the valve’s seating can prevent leaks and maintain proper flow control. If any issues arise, such as the valve sticking or not sealing properly, it's advisable to troubleshoot these problems immediately by inspecting the actuator and ensuring all mechanical connections are tight.

Lastly, always perform a functional test after conducting maintenance on your Pn25 butterfly valve. This test not only confirms that the valve operates correctly but also allows for early detection of any potential issues. Keeping a maintenance log can be helpful for tracking any repairs, replacements, or patterns in valve performance, ultimately aiding in more informed decision-making about your valve system.