Leave Your Message

Choosing the right Pn40 Butterfly Valve can be a daunting task. The market is filled with options, each varying in quality and performance. According to industry expert James Carter, "Selecting a Pn40 Butterfly Valve needs careful consideration of operational conditions." His words remind us that not all valves are created equal.

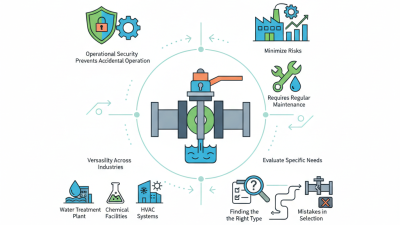

When determining which valve suits your needs, consider the fluid type, temperature, and pressure. Many overlook these critical factors. The Pn40 Butterfly Valve must withstand high pressure while providing reliable flow control. Missing even one detail can lead to costly errors.

Several manufacturers claim to have the best Pn40 Butterfly Valve, but how do you know which one to trust? It’s essential to research and compare specifications thoroughly. Some valves may look good on paper but fail in real-world applications. Reflecting on your needs and seeking knowledgeable advice can streamline this process. In the end, the right choice will enhance overall system efficiency.

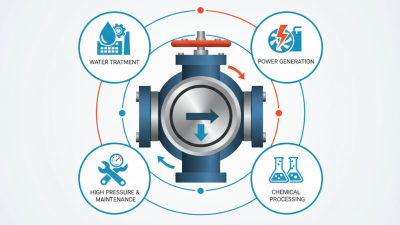

When selecting a PN40 butterfly valve, understanding its specifications is crucial. A PN40 valve can handle a maximum pressure of 40 bar. This high-pressure rating makes it suitable for various applications in water treatment, oil, and gas industries. Typically, these valves also feature a resilient seating material, which enhances their performance and lifespan. Reports from the Valve Manufacturers Association indicate that the right selection can improve efficiency by approximately 15%.

Tips: Always consider the medium you will control. Compatibility is key. Different materials can withstand varying levels of corrosiveness and temperature.

Sizing is another essential aspect. The diameter of the valve should match the pipe size to avoid disruptions in flow. Common sizes range from 2 inches to 36 inches, but custom solutions exist. An industry study highlighted that mismatched sizes can lead to 10% energy loss.

Tips: Regular inspections can prevent costly failures. Look for signs of wear like leaks or unusual noise. Early detection is vital for longevity.

Identifying application requirements is crucial when selecting a PN40 butterfly valve. Each application has unique demands. Key factors include temperature, pressure, and fluid type. For instance, a study by the Valve Manufacturers Association highlights that about 30% of valve failures are due to inappropriate specifications. This emphasizes the need for diligence in understanding requirements.

Pressure ratings are paramount. A PN40 butterfly valve is rated for 40 bar, suitable for high-pressure systems. Temperature tolerance also varies significantly. Fluids like steam require valves that can withstand higher temperatures. A report from the International Society of Automation reveals that improper thermal ratings can lead to valve distortion.

Fluid characteristics matter too. Corrosive fluids require specialized materials. In contrast, water applications may use standard materials. It's critical to assess compatibility to prevent failures. Failures often result in expensive downtime. Precise specifications protect investments and enhance system efficiency. Each detail contributes to longevity and performance.

| Application | Temperature Range (°C) | Pressure Rating (PN) | Material | Size (mm) |

|---|---|---|---|---|

| Water Treatment | 0 to 80 | PN40 | Cast Iron | 50 |

| Food Processing | -20 to 100 | PN40 | Stainless Steel | 100 |

| Chemical Processing | -10 to 120 | PN40 | PVC | 80 |

| HVAC Systems | -20 to 70 | PN40 | Aluminum | 150 |

| Power Generation | 20 to 200 | PN40 | Carbon Steel | 200 |

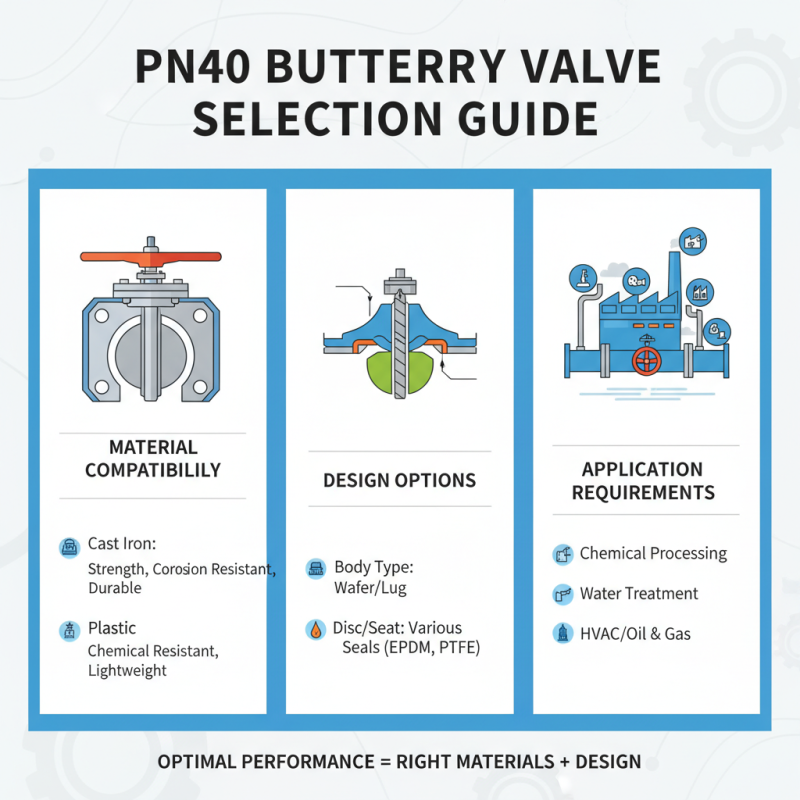

Choosing the right Pn40 butterfly valve involves understanding material compatibility and design options. Each application has unique requirements. Selecting a valve with the right materials ensures durability. Common options include cast iron, stainless steel, and plastic. Each material has different strengths and weaknesses.

For example, stainless steel offers corrosion resistance. However, it may not be ideal for high-acid environments. On the other hand, plastic valves can handle certain chemicals but might not support high temperatures. Evaluating these factors is essential.

Design plays an equally crucial role. You must consider the flow direction and pressure rating. A poorly designed valve can lead to leaks. Think about accessibility for maintenance, too. It’s easy to overlook these details until problems arise. Reflecting on your specific needs will guide your choice.

When selecting a PN40 butterfly valve, it is essential to evaluate various manufacturers. Quality assurance plays a critical role in ensuring the valve operates effectively. Some manufacturers focus on innovative designs, while others emphasize durability. It can be challenging to choose the right option.

Compare the materials used in different valves. Some are made from stainless steel, while others use cast iron. Consider the environment where the valve will be used. Will it face high pressure or corrosive elements? Knowing these factors helps narrow choices.

Customer reviews can offer insights into the performance of various brands. Look for valves that have undergone rigorous testing. Ensure that the manufacturer provides clear warranty information. This can signal confidence in their product. Remember, investing in a quality valve may save costs in the long run. But it’s also essential to trust your instincts. Visiting a supplier or manufacturer can sometimes reveal more than online research.

When considering Pn40 butterfly valves, maintenance is key for longevity. Regular checks can prevent costly failures. According to industry reports, well-maintained valves can last up to 15 years, while neglected ones may fail within five years. Operators often overlook simple maintenance tasks, leading to unexpected downtime.

Scheduled inspections can identify wear and tear early on.

Tips for maintaining Pn40 valves: