Leave Your Message

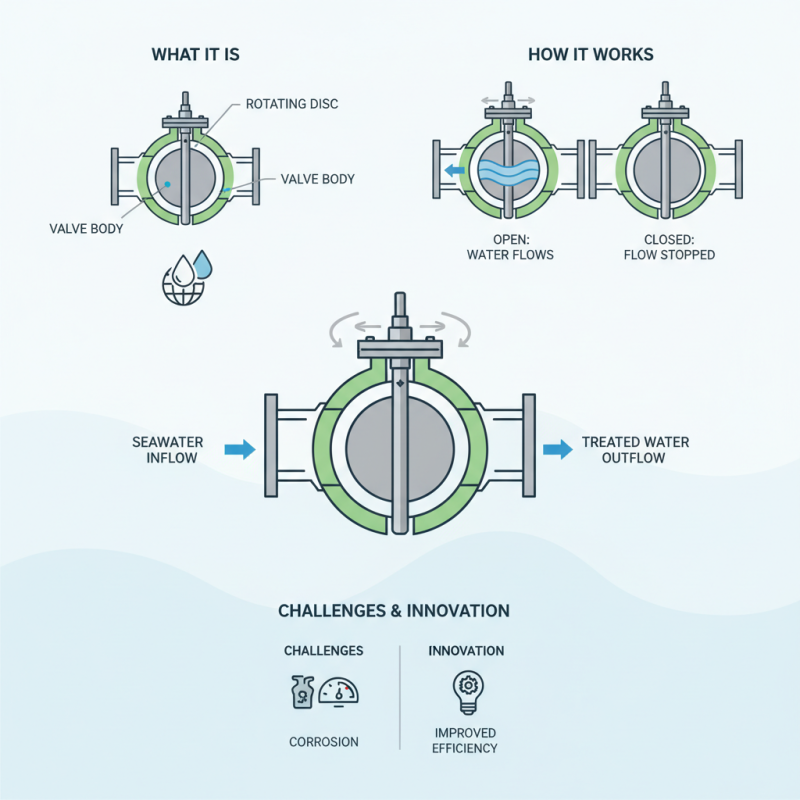

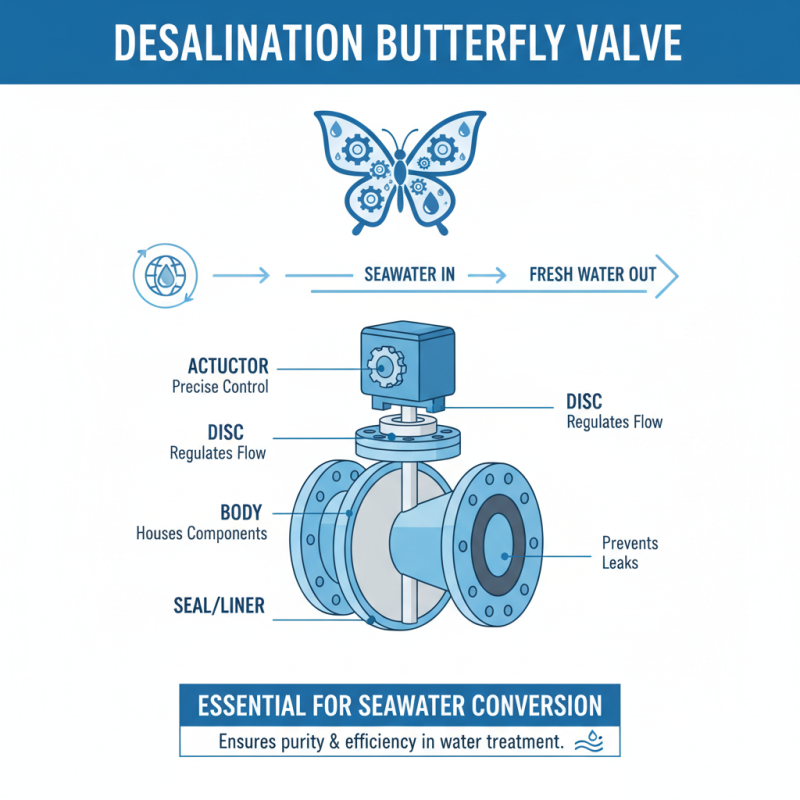

Desalination plays a crucial role in providing clean water worldwide. A vital component in this process is the Desalination Butterfly Valve. This valve controls the flow of seawater through various systems. It features a rounded disc that rotates to open or close the passage.

In the desalination process, these valves must function reliably. They face challenges such as corrosion and varying pressure levels. Many designs aim to improve durability. However, some existing models struggle with efficiency.

Understanding how a Desalination Butterfly Valve works can help streamline operations. It could lead to better performance and maintenance practices. As we explore this technology, we should consider areas for improvement and innovation.

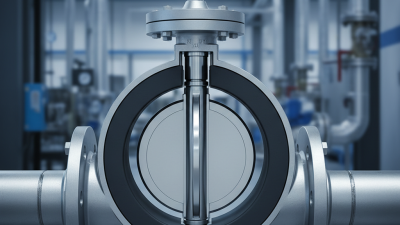

A desalination butterfly valve is a crucial component in desalination systems. It controls the flow of seawater and brine, ensuring efficient operation. This type of valve is designed with a disc that rotates to open or close the flow path. When the disc is parallel to the flow, the valve is fully open. When it's turned 90 degrees, the flow is stopped. Such operations are vital for maintaining pressure and preventing backflow.

These valves are often made of corrosion-resistant materials. They need to withstand harsh marine environments. Proper installation is essential to ensure optimal performance. However, sometimes users overlook maintenance. Regular checks are important to avoid leaks. A malfunctioning valve can lead to costly downtime. In a world where water scarcity is growing, every drop counts. It's critical to prioritize the reliability of these valves to guarantee continuous supply in desalination plants.

| Feature | Description |

|---|---|

| Type | Butterfly Valve |

| Material | Corrosion-resistant materials such as stainless steel or plastic |

| Function | Controls the flow of seawater during desalination |

| Operating Mechanism | Rotates 90 degrees to either open or close the valve |

| Advantages | Lightweight, low pressure drop, quick operation |

| Applications | Used in desalination plants, water treatment facilities, and industrial applications |

| Maintenance | Regular inspections and cleaning to prevent corrosion and buildup |

A desalination butterfly valve is essential in water treatment processes. It ensures precise control in systems that convert seawater into fresh water. The valve consists of several key components that contribute to its functionality.

One critical part is the disc. The disc rotates to regulate flow. It’s usually circular and positioned at the center. The actuation mechanism, which can be manual or automatic, opens and closes the disc smoothly. This operation minimizes turbulence and prevents damage. Additionally, the body of the valve is designed to withstand high pressure, which is common in desalination plants.

**Tip:** Regular maintenance is crucial for valve longevity. Inspect seals and gaskets often to prevent leaks.

Another important component is the seat. This part provides a sealing surface when the valve is closed. The material used here is vital. It must resist corrosion and wear. Each component plays its role in ensuring efficiency and reliability. Without proper care, even a small component malfunction can lead to larger system inefficiencies.

**Tip:** Consider using monitoring systems to track the valve's performance consistently. This helps in identifying potential issues early on.

Desalination butterfly valves play a crucial role in the water treatment process. They control the flow of seawater and desalinated water. Understanding how they work is essential for effective management.

The mechanism relies on a circular disc that rotates within the valve body. When the valve opens, the disc aligns with the flow path. This action allows water to pass through freely. When the valve closes, the disc turns perpendicular to the flow. This creates a tight seal to prevent leaks.

However, precision is vital in this operation. A misaligned valve can disrupt flow rates. Maintenance is also key to ensure longevity. Sometimes, wear and tear can cause inefficiency. Regular checks can prevent these issues. Contaminants in the system can lead to malfunction, leading to water quality concerns. This makes awareness and proactive maintenance essential in desalination facilities.

This chart illustrates the performance metrics of different types of desalination butterfly valves based on their flow rates and pressure drops under varying conditions.

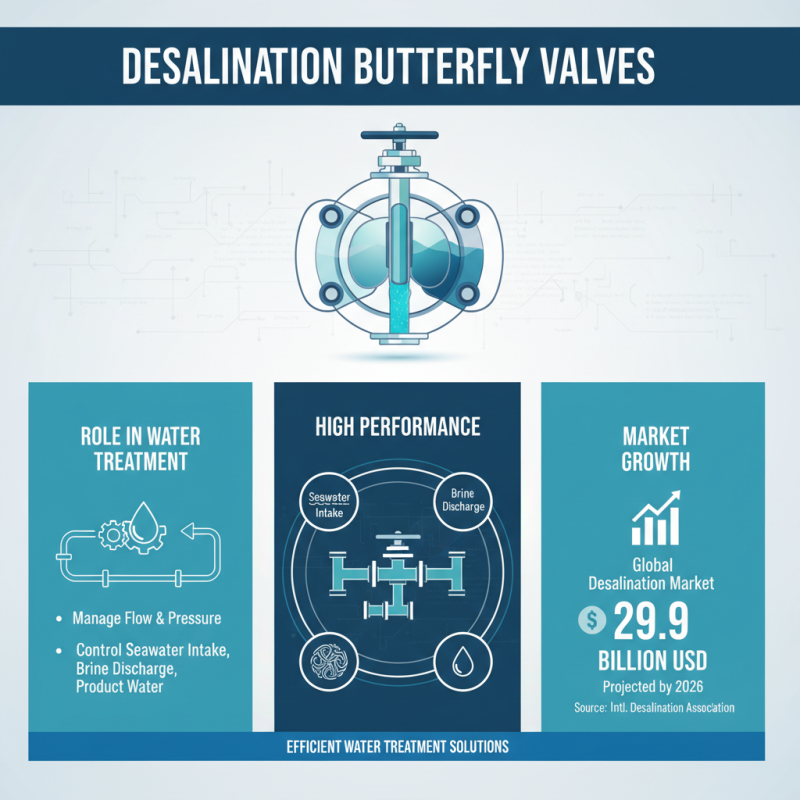

Desalination butterfly valves play a crucial role in water treatment processes. They are essential for managing flow and pressure in desalination plants. These valves offer high performance in controlling seawater intake, brine discharge, and product water output. According to a report from the International Desalination Association, the global desalination market is projected to reach $29.9 billion by 2026, highlighting the demand for efficient water treatment solutions.

In many modern desalination facilities, butterfly valves help to ensure optimal operation. Their lightweight design allows for quick opening and closing. This feature is vital when dealing with volatile saline conditions. Research indicates that these valves can handle varying pressures and have an operational lifespan of over 30 years. However, the effectiveness of these valves can diminish if not regularly maintained. Issues such as wear and tear can lead to leakage, impacting efficiency.

Applications extend beyond just desalination. These valves are crucial in various sectors, such as agriculture and industrial processes, where purified water is necessary. The versatility of desalination butterfly valves makes them an asset in enhancing water quality management. Despite their efficiency, some facilities face challenges in integrating them with existing systems. This gap often leads to operational inefficiencies and increased costs, which call for careful consideration.

Butterfly valves are essential in desalination processes. They provide efficient flow control and are known for their lightweight and compact design. According to a recent report from the International Water Association, the use of butterfly valves can reduce energy consumption by up to 30% in desalination plants. This efficiency is crucial, considering that desalination is an energy-intensive process.

One major advantage of butterfly valves is their ease of operation. They can be automated, allowing for precise flow regulation. In terms of maintenance, they typically require less attention compared to other valve types. However, there are challenges. The seating surfaces may wear out faster due to high pressure and flow rates, leading to leaks. Regular inspections are needed to ensure optimal performance.

Tips: Regularly check your butterfly valves for signs of wear. This can prevent unexpected downtime. Also, consider the valve size and pressure rating carefully. An incorrectly sized valve can lead to inefficiencies. Proper selection is key to maximizing the benefits of these valves in desalination processes.