Leave Your Message

In the realm of industrial applications, the choice of valve materials plays a critical role in ensuring operational efficiency and longevity. Ebonite Lining Butterfly Valves have emerged as a preferred solution for various sectors due to their unique properties, particularly in handling abrasive and corrosive fluids. According to a recent industry analysis by MarketsandMarkets, the global butterfly valve market is expected to grow substantially, reaching an estimated value of $8.7 billion by 2026, as industries seek reliable and durable valve solutions.

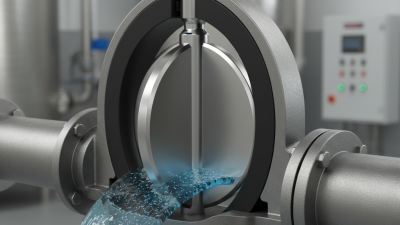

Ebonite, a hard rubber compound known for its resilience and resistance to chemicals, presents significant advantages in demanding environments. The adoption of Ebonite Lining Butterfly Valves can reduce maintenance costs and enhance system reliability. For instance, studies have shown that valves with Ebonite linings can operate effectively in temperature ranges up to 120°C and offer improved wear resistance against harsh media, making them suitable for applications in chemical processing and wastewater management.

Furthermore, the increasing emphasis on sustainable practices in industry is propelling the demand for components that minimize leaks and energy loss. Ebonite Lining Butterfly Valves offer tight sealing capabilities, contributing to reduced emissions and better environmental compliance. With these compelling benefits, it is clear that Ebonite Lining Butterfly Valves are becoming an indispensable component in modern industrial operations, addressing both efficiency and sustainability concerns.

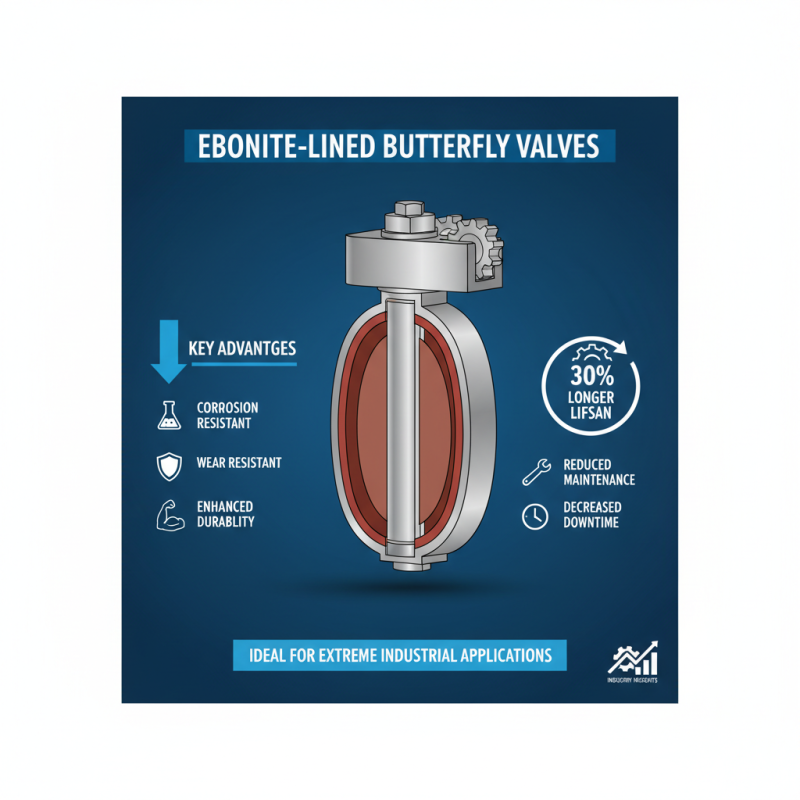

Ebonite lining in butterfly valves offers significant advantages for various industrial applications, particularly in environments that demand resilience against corrosion and wear. The robust properties of ebonite, a type of vulcanized rubber, enhance the overall durability of butterfly valves. According to a recent industry report, valves lined with ebonite can withstand extreme conditions and exhibit a life span that is 30% longer than those lined with traditional materials, effectively reducing maintenance costs and downtime.

Utilizing ebonite lining not only protects the valve body but also improves flow characteristics. The smooth surface of ebonite minimizes turbulence, allowing for efficient fluid movement. This is especially critical in industries such as chemical processing and water treatment, where operational efficiency is paramount. For instance, a study indicated that ebonite-lined valves could reduce energy consumption by up to 15% compared to conventional valve linings, translating to substantial cost savings over time.

Tips: When selecting butterfly valves for your application, consider the specific environmental conditions, including temperature and chemical exposure. Ebonite linings are particularly effective for handling aggressive media, so ensure compatibility for optimal performance. Regular inspections can also enhance the longevity of your valves, as proactive maintenance is key to avoiding costly replacements.

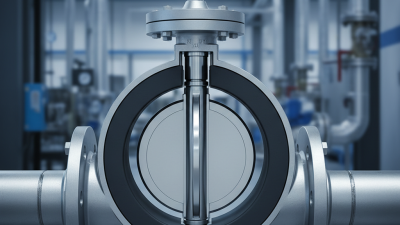

Butterfly valves are widely used in various industrial settings due to their simplicity, reliability, and efficiency in regulating flow. Common applications of butterfly valves include water treatment facilities, HVAC systems, chemical processing plants, and food and beverage manufacturing. Their design allows for quick operation, enabling them to open and close with just a quarter turn, which is particularly advantageous in systems that require frequent adjustments.

In chemical processing industries, for example, butterfly valves play a crucial role in managing the flow of corrosive and viscous fluids. They ensure tight sealing and reduced leakage, minimizing environmental impact and enhancing operational safety. Similarly, in water treatment plants, they are essential for controlling the flow of water through various stages of purification and distribution, contributing to the overall efficiency of the system.

Tip: When selecting butterfly valves for industrial applications, consider the material compatibility with the fluids being handled. Ebonite lining can offer enhanced corrosion resistance, making it a preferred choice for aggressive chemicals. Always consult with engineers or valve specialists to ensure optimal performance and longevity in your specific application environment.

Tip: Regular maintenance of butterfly valves is key to preventing unexpected breakdowns. Implement a routine inspection schedule that focuses on the valve’s seals, actuator functionality, and any signs of wear or corrosion. This proactive approach can significantly extend the lifespan of your valve and improve system reliability.

When it comes to selecting lining materials for butterfly valves in industrial applications, the comparative durability of ebonite versus traditional linings plays a crucial role in ensuring reliable performance. Ebonite linings are recognized for their superior resistance to wear and tear, outperforming standard rubber and neoprene linings in demanding environments. According to a recent study by the American Society of Mechanical Engineers (ASME), ebonite can withstand abrasive conditions up to three times longer than traditional materials, making it a cost-effective option for industries that require durability under high pressure and aggressive fluid conditions.

Additionally, ebonite possesses excellent resistance to various chemical agents found in industrial settings. A report from the Chemical Engineering Magazine highlighted that ebonite linings experienced less than 5% degradation when exposed to strong acids and bases over a six-month period, while conventional linings showed significant deterioration. This enhanced chemical resilience leads to longer service life and reduced maintenance costs, further solidifying ebonite's status as a preferred choice for valves used in harsh operational environments. As industries continue to seek high-performance materials to optimize operations, ebonite lined butterfly valves stand out for their durability and longevity, ensuring uninterrupted workflow and safety in demanding applications.

| Property | Ebonite Lining | Traditional Linings |

|---|---|---|

| Chemical Resistance | Excellent | Good |

| Temperature Tolerance | Up to 120°C | Up to 100°C |

| Wear Resistance | High | Moderate |

| Life Expectancy | 10+ years | 5-7 years |

| Maintenance Frequency | Low | Moderate |

Ebonite lining in butterfly valves provides a cost-effective solution for various industrial applications, particularly in environments exposed to harsh chemicals and abrasive materials. The durability of ebonite significantly reduces wear and tear over time, minimizing the need for frequent replacements. This longevity translates into lower maintenance costs and fewer operational disruptions, allowing industries to allocate resources more efficiently and maximize productivity.

Moreover, the exceptional resilience of ebonite lining against corrosion and extreme temperatures enhances the overall performance of butterfly valves. As facilities aim to optimize their operational expenses, the initial investment in ebonite-lined valves pays off in the long run. By limiting repair costs and extending the service life of equipment, businesses can achieve substantial savings. Not only does this contribute to a more sustainable approach to resource management, but it also highlights the strategic advantage of choosing ebonite lining for valves in demanding industrial settings.

Ebonite lined butterfly valves are increasingly favored in industrial applications due to their superior resistance to wear and corrosion, thanks to the durable Ebonite lining. When it comes to maintenance considerations of these valves, it is essential to recognize their unique material properties. According to industry reports, Ebonite provides excellent resistance against aggressive chemicals and high temperatures, which significantly extends the operational lifespan of the valves compared to traditional materials. This durability reduces the frequency of maintenance interventions, making them a cost-effective solution in the long run.

However, regular inspections are still crucial to ensure optimal performance. Industry standards recommend routine checks for leaks, wear on the Ebonite lining, and the proper functioning of the valve mechanism. A study by the Valve Manufacturers Association indicates that preventive maintenance strategies can lead to a 30% reduction in unexpected valve failures. Operators should also consider environmental factors, such as temperature fluctuations and humidity, which can impact the performance of the Ebonite lining. Implementing a maintenance schedule that accounts for these variables ensures that the valves operate efficiently and safely over time.