Leave Your Message

In the realm of industrial applications, the En1074 Butterfly Valve plays a crucial role in regulating fluid flow and maintaining system efficiency. Industry expert Dr. John McAllister, a renowned engineer with over two decades of experience in fluid dynamics, emphasizes the significance of this valve by stating, "The En1074 Butterfly Valve not only enhances the performance of fluid control systems but also ensures reliability and safety in various industrial processes." This assertion highlights the valve's indispensable function in modern operational frameworks.

The En1074 Butterfly Valve is designed with a unique disc that rotates within the flow stream, allowing for precise control over the flow rate. Its compact design and lightweight nature make it an ideal choice for installations where space and weight are critical considerations. As industries continue to evolve, the need for efficient and effective fluid management solutions becomes more pronounced, making the En1074 Butterfly Valve an essential component in a variety of sectors, including water treatment, power generation, and chemical processing.

Understanding the mechanics and applications of the En1074 Butterfly Valve is vital for engineers and operators alike, as it directly affects the performance of entire systems. With its ability to withstand high pressures and its ease of maintenance, this valve stands out as a reliable choice for many industrial settings. As we delve deeper into its functionalities and applications, it becomes clear that the En1074 Butterfly Valve is not just a component, but a cornerstone of industrial fluid management.

The EN1074 butterfly valve is a critical component used in various industrial applications for regulating and controlling fluid flow. This valve type conforms to the European standard EN 1074, which specifies the requirements for valves used in water supply and sewage systems. Known for its efficient design, the EN1074 butterfly valve features a disk that rotates to open or close the flow passage, allowing for quick operation and minimal pressure drop. The simplicity of its design not only reduces manufacturing costs but also ensures ease of maintenance, making it a favored choice in diverse environments, from water treatment facilities to chemical processing plants.

Industry reports highlight that the butterfly valve market is projected to grow significantly, driven by increasing investments in water and wastewater management projects. According to a recent analysis, the global butterfly valve market is expected to reach approximately $13 billion by 2026, with an annual growth rate of around 6.8%. The EN1074 butterfly valve, with its robust construction and operational reliability, plays a pivotal role in meeting the rising demand for efficient fluid control mechanisms. Furthermore, this valve's ability to perform under high pressures and temperatures makes it suitable for a variety of applications, including HVAC systems and petrochemical processes, thus solidifying its status as a versatile solution in industrial settings.

The EN1074 Butterfly Valve is widely used across various industries due to its efficient design and reliability. The chart above illustrates the performance rating of these valves in five different applications, highlighting their effectiveness in each sector.

The EN1074 butterfly valve is designed specifically for water supply systems, showcasing a range of key features that enhance its functionality within industrial applications. Manufactured to meet rigorous industry standards, these valves typically operate in temperatures up to 70 degrees Celsius and are capable of handling pressures of up to 16 bar. The construction usually includes ductile iron or cast steel bodies and an EPDM or NBR rubber lining, ensuring both durability and resilience against corrosive environments. According to the "Valve Market Report" by Research and Markets, the demand for reliable butterfly valves in sectors such as water treatment and wastewater management is projected to grow by over 5% annually through 2025, indicating a robust market need for solutions like the EN1074.

One of the critical specifications of the EN1074 butterfly valve is its disc design, which enhances flow characteristics and minimizes turbulence, resulting in improved efficiency and reduced energy consumption. The valve's compact design allows for easy installation and maintenance, a necessity in high-demand industrial settings. Furthermore, the size range typically varies from DN 50 to DN 1500, enabling its application across diverse pipeline sizes. The "Global Industrial Valves Market" by Allied Market Research forecasts that rising infrastructural developments will further amplify the utility of EN1074 butterfly valves, driving innovations in manufacturing processes and the introduction of more advanced materials that extend the lifecycle of these vital components.

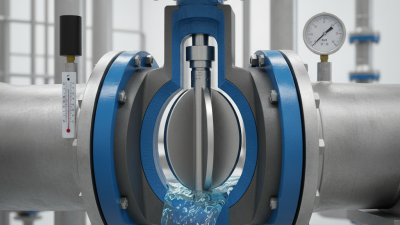

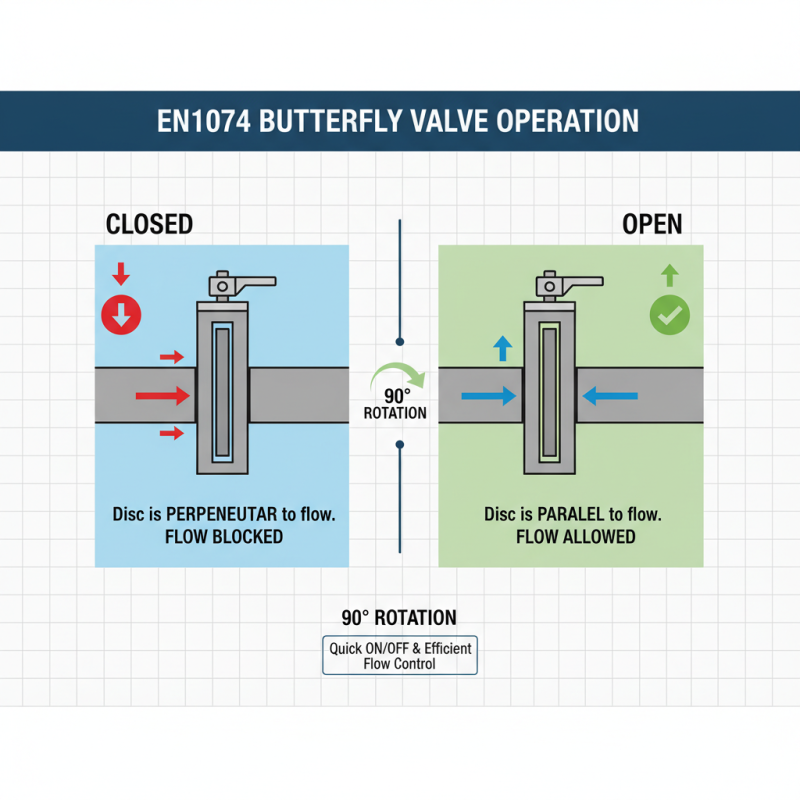

EN1074 butterfly valves are designed to manage the flow of liquids and gases in various industrial applications. Their operation is based on a simple yet effective mechanism that utilizes a rotating disc. When the valve is closed, the disc is perpendicular to the flow, effectively blocking it. Conversely, when the valve is opened, the disc rotates 90 degrees, allowing flow to pass through with minimal resistance. This straightforward operation not only facilitates quick opening and closing but also contributes to efficient flow management in pipelines.

In industrial settings, EN1074 butterfly valves are particularly valued for their compact design and lightweight characteristics, making them suitable for installations where space is a constraint. They can be found in water treatment facilities, chemical processing plants, and HVAC systems, among others. Their ability to maintain a tight seal and withstand varying pressure levels ensures reliability in demanding environments. Additionally, the construction materials used in these valves can be tailored to resist corrosion, making them ideal for handling various aggressive substances. The versatility and efficiency of EN1074 butterfly valves in controlling flow make them a staple in diverse industrial operations.

EN1074 butterfly valves are widely utilized across various industrial applications due to their efficiency and versatility in controlling fluid flow. One of the most common applications is in water treatment plants, where they are used for regulating the flow of water in pipelines. Their quick operation and compact design allow for seamless integration into existing systems, enabling operators to manage water supply effectively and maintain the desired pressure levels.

Another significant application of EN1074 butterfly valves can be found in HVAC systems, where they help manage airflow within building ventilation systems. These valves provide excellent throttling capabilities, allowing for precise control over the distribution of air. Additionally, they are employed in the chemical processing industry to handle corrosive fluids, owing to their robust construction. With their ability to withstand harsh environments, EN1074 butterfly valves ensure operational reliability while minimizing maintenance costs in demanding settings.

EN1074 butterfly valves are increasingly utilized in various industrial applications, particularly within fluid control systems. One of the primary benefits of these valves is their design, which allows for quick and efficient operation. The quarter-turn functionality enables operators to easily open or close the valve with minimal effort, making it ideal for scenarios requiring frequent adjustments. This ease of use translates into enhanced operational efficiency, particularly in environments where time-sensitive decisions are crucial.

Additionally, EN1074 butterfly valves offer significant advantages in terms of space efficiency and weight reduction compared to traditional valve types. Their compact design allows for installation in restricted spaces without compromising flow capacity. This characteristic is especially beneficial in large-scale industrial setups where maximizing space utilization is essential. Furthermore, the lightweight construction facilitates easier handling and installation, which can lead to lower labor costs and reduced downtime during maintenance. In summary, the incorporation of EN1074 butterfly valves not only enhances fluid control precision but also optimizes operational efficiency across various industrial applications.

| Feature | Description |

|---|---|

| Body Material | Cast Iron, Stainless Steel, or Plastic |

| Operation Type | Manual or Automated |

| Temperature Range | -10°C to 80°C (14°F to 176°F) |

| Pressure Rating | Up to 16 Bar (232 psi) |

| Applications | Water Supply, Wastewater Treatment, Chemical Processing |

| Advantages | Low Flow Resistance, Compact Size, Cost-Effective |

| Maintenance | Minimal, Replaceable Seals |