Leave Your Message

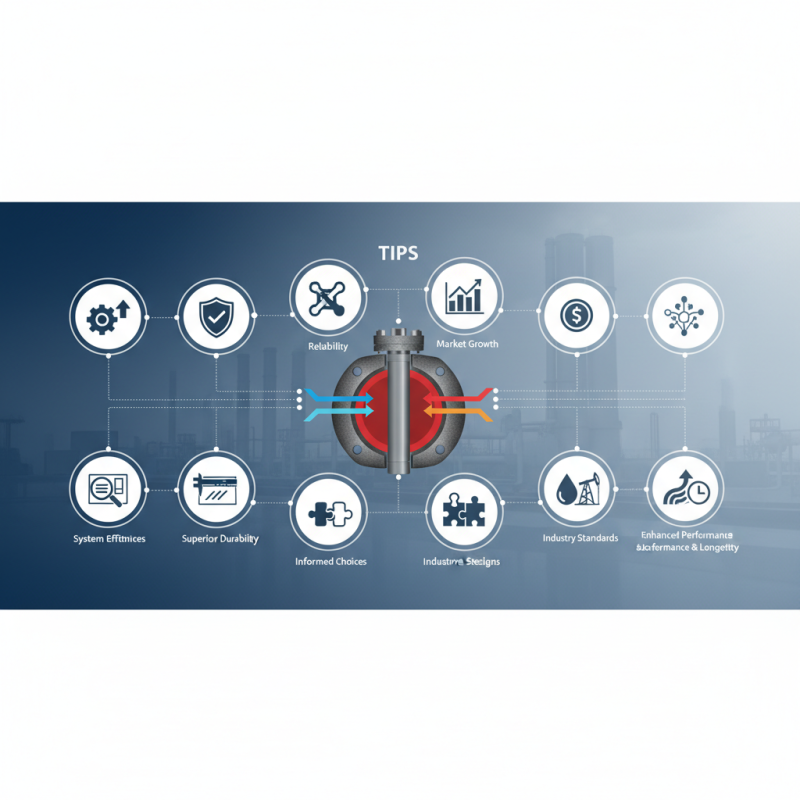

When it comes to industrial applications, selecting the appropriate valves is crucial for ensuring system efficiency and reliability. One of the standout options in the market is the Ggg40 Butterfly Valve, which is praised for its robustness and versatility. According to a recent report by the Industrial Valve Manufacturers Association, the global market for butterfly valves is expected to grow by 5.4% annually, with the Ggg40 variant gaining significant traction due to its superior durability and cost-effectiveness.

Industry expert Dr. Alan Miller, a renowned valve design engineer, emphasizes the importance of making informed choices in this space: "Choosing the right valve, such as the Ggg40 Butterfly Valve, can make or break a system's performance." With its unique material composition and innovative design, the Ggg40 Butterfly Valve not only meets industry standards but also addresses specific operational challenges faced by engineers today.

As we delve deeper into the essentials of selecting the right Ggg40 Butterfly Valve, this guide will provide you with valuable insights and practical tips, ensuring that your decision-making process is guided by industry best practices and expert recommendations. Whether you are involved in water treatment, oil and gas, or any other industrial sector, understanding these key factors will contribute to enhanced performance and longevity of your systems.

When selecting a GGG40 butterfly valve, it's crucial to understand the key specifications that will impact its performance and suitability for your application.

One of the main factors to consider is the valve size, which should be compatible with the pipe dimensions to ensure optimal flow and pressure management. Additionally, the operating pressure and temperature ratings should align with the specific requirements of your system, as GGG40 cast iron valves are suitable for various environments but have limitations that need careful assessment.

Another important aspect to consider is the valve design and sealing mechanism. The type of seat material can significantly influence the valve's ability to effectively seal against leaks and maintain pressure, so it’s important to choose a design that meets your operational demands.

Furthermore, you may want to evaluate the flow characteristics of the valve, as different designs can affect flow rate and turbulence, which can impact system efficiency. Understanding these specifications will help ensure that the selected butterfly valve meets the operational demands and enhances overall system reliability.

When selecting a Ggg40 butterfly valve, the material properties play a crucial role in its performance and longevity. Ggg40 is a cast iron alloy known for its excellent strength and corrosion resistance, making it an ideal choice for various industrial applications. This alloy contains a balanced mix of carbon and silicon, providing not only favorable mechanical properties but also a surface that withstands corrosion from various chemicals and environmental conditions. Understanding the impact of these material characteristics is essential for ensuring the valve's operational reliability in demanding applications.

Corrosion resistance is particularly important in environments where the valve will be exposed to aggressive fluids or elevated temperatures. Ggg40's formulation resists oxidation and deterioration, thus minimizing maintenance costs and downtime associated with valve failure. Additionally, using a valve constructed from Ggg40 can lead to enhanced safety, as the material's durability ensures that it can handle the pressure and flow requirements without compromising integrity. When assessing butterfly valves, it is vital to consider these material attributes to ensure that the selected valve meets the specific needs of the application while providing robust and long-lasting performance.

| Tip | Description | Material Strength (MPa) | Corrosion Resistance Rating | Applications |

|---|---|---|---|---|

| 1. Know the Environment | Assess the operating conditions and environmental factors that could impact valve performance. | 250 | Moderate | Water Treatment, Wastewater Management |

| 2. Check Compatibility | Ensure the valve materials are compatible with the fluids being handled. | 300 | High | Chemical Processing, Pharmaceutical |

| 3. Evaluate Pressure Ratings | Determine maximum pressure requirements according to system specifications. | 230 | Moderate | HVAC, Oil & Gas |

| 4. Look for Certifications | Select valves with proper certifications for safety and performance. | 350 | High | Public Infrastructure, Power Generation |

| 5. Assess Maintenance Needs | Consider the ease of maintenance and availability of replacement parts. | 280 | Moderate | Water Supply, Industrial Applications |

When selecting a GGG40 butterfly valve, accurately calculating flow requirements is crucial to ensuring optimal performance and longevity of the valve in your system. The flow capacity of a butterfly valve is typically characterized by the Cv (flow coefficient), which reflects the amount of water (in gallons per minute) that can flow through a valve with a pressure drop of 1 psi. According to industry standards, understanding the specific application requirements—for instance, the type of fluid, pressure, and temperature—is essential when determining the appropriate valve size and flow capacity.

To calculate flow requirements accurately, one can use the equation Q = Cv × √(ΔP / SG), where Q represents the flow rate, ΔP is the pressure drop across the valve, and SG is the specific gravity of the fluid. Industry studies suggest that a significant portion of valve failures stems from improper sizing, with estimates indicating that over 30% of installations do not meet their operational requirements due to inadequate flow calculations. Thus, it’s imperative to utilize precise data regarding the system conditions and expected operational behavior, ensuring the selected GGG40 butterfly valve not only fits but also performs under the anticipated stress and flow conditions. This meticulous approach aids in avoiding costly replacements and downtime, contributing to the overall efficiency of fluid management systems.

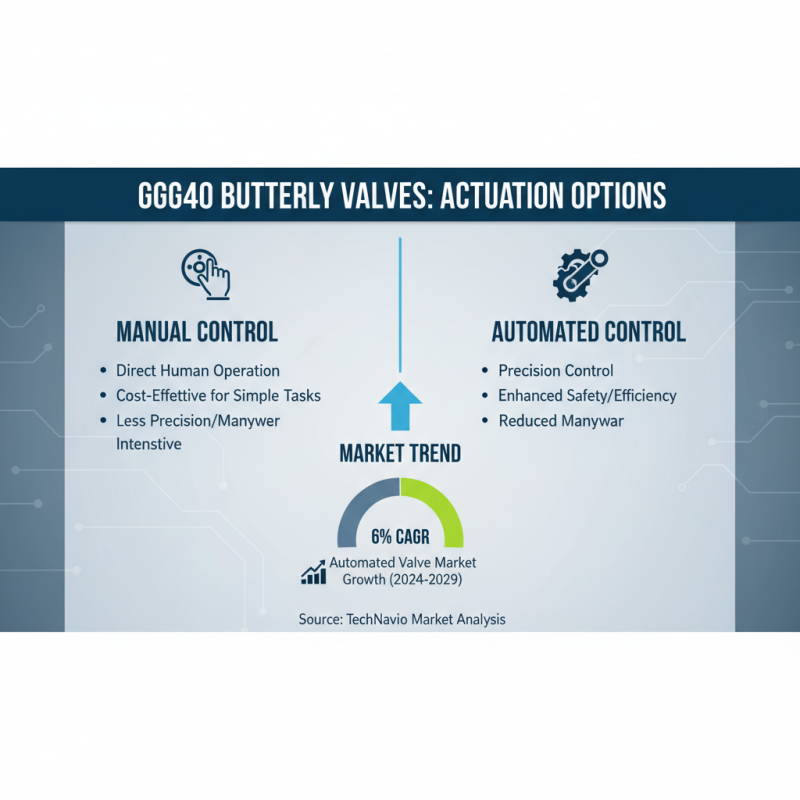

When selecting Ggg40 butterfly valves, one critical decision revolves around the actuation options—manual versus automated control. According to a recent market analysis by TechNavio, the demand for automated valves is projected to grow significantly, with an expected annual growth rate of over 6% in the next five years. This growth is largely driven by increasing demands for operational efficiency and safety in various industrial applications. Automated Ggg40 butterfly valves offer precision control and reduced manpower, making them an attractive choice for facilities looking to optimize their workflows.

On the other hand, manual valves still play a vital role in many operations. Reports from the Valve Manufacturers Association indicate that manual valve systems can provide high reliability and lower initial costs, particularly in environments where the frequency of valve operation is minimal. For organizations faced with budget constraints or where simplicity and straightforwardness are paramount, manual actuation remains a dependable option. Understanding the specific requirements of your application—such as the environment, frequency of use, and control complexity—is essential when deciding between manual and automated actuation for Ggg40 valves.

When selecting the right GGG40 butterfly valve, understanding industry standards and certifications is crucial to ensure compliance and quality. Various organizations, such as the American Society of Mechanical Engineers (ASME) and the International Organization for Standardization (ISO), provide guidelines that help manufacturers meet rigorous criteria for performance and safety. According to a 2022 report from the International Valve Manufacturing Association, compliance with these standards can significantly reduce the risk of valve failure in applications involving fluctuating pressure and temperature.

Additionally, certifications such as the Pressure Equipment Directive (PED) in Europe and the American National Standards Institute (ANSI) certifications play a vital role in assuring end-users of the reliability and quality of butterfly valves. A recent study indicated that valves that meet these certifications demonstrate a drop in operational failures by nearly 30% compared to non-compliant products. By prioritizing valves that adhere to these industry norms, users can ensure they are investing in durability and efficiency, ultimately leading to improved operational performance and reduced maintenance costs.