Leave Your Message

Choosing the right Hydraulic Control Valve is crucial for any hydraulic system. Experts like John Smith, a renowned engineer in fluid dynamics, emphasize, “The right valve can make or break a hydraulic system.” It’s not just about functionality; it’s about performance and reliability.

When selecting a Hydraulic Control Valve, consider various factors. Understand the required flow rates and pressure ratings. A mismatch can lead to inefficiencies or even failures. Common pitfalls include overlooking the valve's compatibility with other system components. Such oversights can be costly.

Furthermore, don’t ignore the environmental factors. Temperature fluctuations can affect valve behavior. Regularly evaluate your choice and be ready to adapt. Finding the perfect Hydraulic Control Valve requires reflection and foresight. Wrong choices can lead to leaks and downtime. A thoughtful approach is necessary for optimal efficiency.

When selecting a hydraulic control valve, several factors come into play. The application of the system is crucial. Will it handle high pressure or low flow? Understand the system's requirements before making a choice. The valve's size must match the flow rate. An oversized valve can lead to ineffective performance. An undersized valve may cause excessive wear.

Another important consideration is the fluid type. Different fluids may require specific materials for the valve. Corrosion resistance becomes vital in harsh environments. Check for compatibility to prevent failures. Temperature ranges can also influence the valve's lifespan. Some valves perform poorly in extreme conditions.

It's easy to overlook maintenance needs. A valve that is hard to access may become neglected. Regular checks are essential for longevity. Choosing a valve with accessible features will facilitate easier maintenance. Balancing all these factors creates a more reliable fluid system. Too often, the decision is rushed. Taking time to evaluate each aspect can prevent costly mistakes down the line.

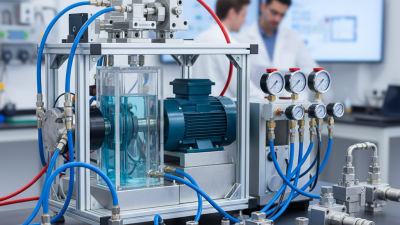

When selecting a hydraulic control valve, understanding flow rate requirements is crucial. Flow rate impacts the valve's efficiency and performance. According to industry reports, the right flow rate ensures optimal operation within the system. Underestimating or overestimating flow can lead to inefficiencies, causing potential failures.

Valves should match the specific demands of the application. For example, a typical hydraulic system might require a flow rate of 10 to 150 gallons per minute (GPM). A mismatch could waste energy or reduce overall functionality. Achieving the desired flow rate often demands a careful evaluation of pressure and viscosity parameters. Many users neglect to analyze these factors, which can lead to equipment malfunction or suboptimal operation.

Evaluating the environmental conditions is equally important. External temperatures can affect fluid viscosity, altering flow rates. A report from the Hydraulic Institute reveals that improper flow rates can decrease valve lifespan significantly. Users often overlook these aspects in a rush to implement solutions. Taking the time to ensure the right specifications can prevent future headaches and ensure a smoother operation.

| Tip Number | Tip Description | Flow Rate Requirement (GPM) | Valve Size (inches) | Suitable Applications |

|---|---|---|---|---|

| 1 | Assess your system's maximum flow rate. | 10 | 2 | Excavators, Loaders |

| 2 | Consider the required pressure ratings. | 15 | 2.5 | Trucks, Hydraulic Presses |

| 3 | Choose a valve that matches your hydraulic fluid type. | 20 | 3 | Agricultural Machinery |

| 4 | Evaluate the environmental conditions and temperature ranges. | 25 | 4 | Mining Equipment |

| 5 | Select the appropriate actuation method (manual, electric, etc.). | 30 | 4.5 | Construction Equipment |

| 6 | Consider the response time required for your application. | 35 | 5 | Cranes |

| 7 | Assess compatibility with existing components in your system. | 40 | 6 | Marine Applications |

| 8 | Look for features such as flow control and pressure relief. | 45 | 7 | Industrial Applications |

| 9 | Evaluate maintenance requirements and accessibility. | 50 | 8 | Robotics |

| 10 | Seek expert advice if unsure about valve selection. | 60 | 10 | Power Generation |

When selecting a hydraulic control valve, pressure ratings are critical. A valve's pressure rating determines its ability to withstand the system's operational requirements. If this rating is too low, it can lead to failures. In contrast, a valve rated too high may result in unnecessary costs. The right balance is vital.

Consider the operating environment. Temperature, fluids, and other factors impact pressure ratings. For example, a valve may perform well under standard conditions but fail under extreme temperatures. It's essential to account for these variables in your evaluation. Always consult with experts if uncertain; they can provide insights about specific applications.

Don't rush into decisions. Take your time to understand the specifications. Testing and validation are necessary steps. Sometimes, the safest option isn’t the most apparent. Reflecting on past experiences can guide you. Analyze what worked and what didn't. Having the right pressure rating ensures safety and functionality in hydraulic systems.

This chart displays the pressure ratings (in psi) of various types of hydraulic control valves to evaluate their suitability and safety for different applications. Higher pressure ratings indicate the valve's capability to handle more demanding situations.

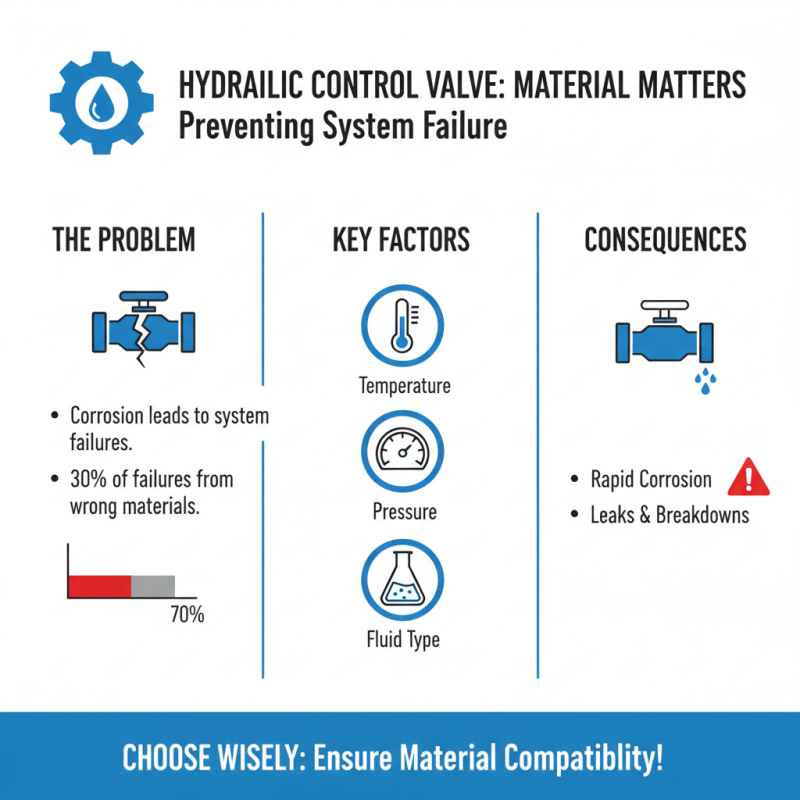

When selecting a hydraulic control valve, material compatibility is paramount. Corrosion can lead to system failures. Data from industry reports show that improper material choices can cause up to 30% of hydraulic system failures. Factors such as temperature, pressure, and fluid type must be considered. A valve made of incompatible materials can corrode quickly, causing leaks and breakdowns.

Tip: Always evaluate the fluid you are using. Different fluids have varying levels of corrosiveness. For example, petroleum-based fluids may affect certain metals differently than water-based fluids. Testing compatibility with specific materials is crucial. It’s not just about the valve itself; the entire system must be compatible.

Another consideration is the environment in which the valve operates. Humidity, temperature swings, and exposure to chemicals can all accelerate corrosion. According to research, systems in corrosive environments see failure rates increase dramatically. Regular inspections and proper maintenance can mitigate risks, but initial material selection is key.

Tip: Consult with material specialists when unsure. Their expertise can guide you toward the right choices. Avoiding guesswork can save time and costs. Don't overlook the importance of thorough analysis. Choices made without adequate assessment can lead to prolonged outages and costly repairs.

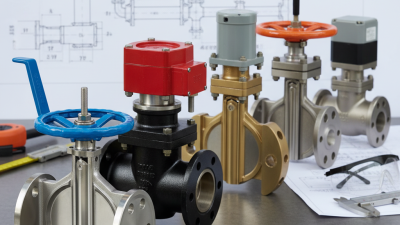

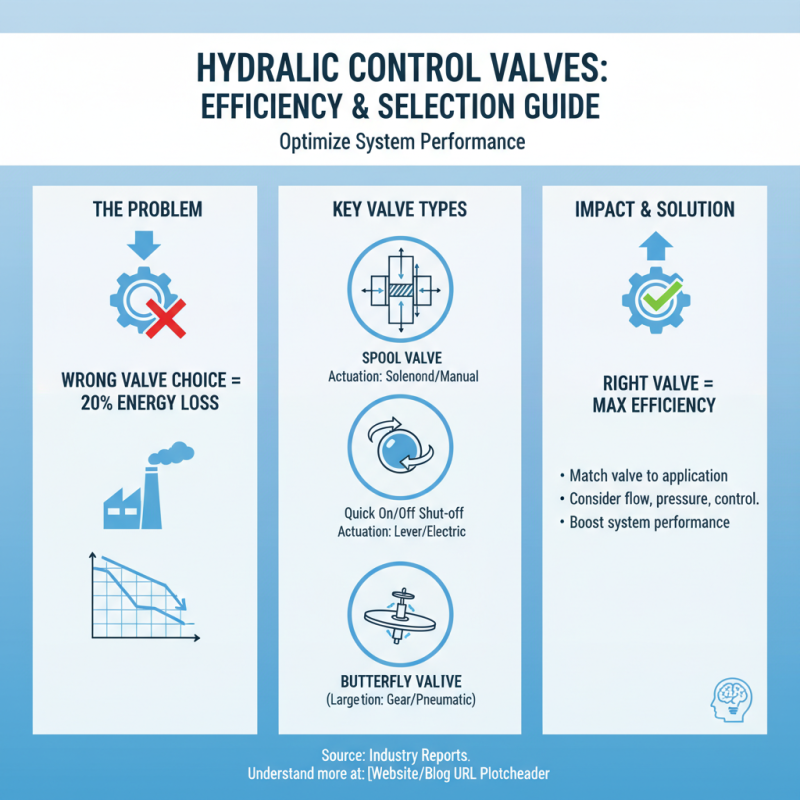

Hydraulic control valves play a crucial role in system efficiency. Their types and actuation methods significantly impact performance. According to industry reports, selecting the wrong valve type can lead to a 20% decrease in energy efficiency. It's vital to understand the differences between spool, ball, and butterfly valves. Each type serves specific applications, but confusion often arises.

Actuation methods also matter greatly. Operators can choose between manual, electric, or pneumatic actuation. Electric actuators provide precision but may have higher upfront costs. Pneumatic options can quickly respond to changes but might require a reliable air supply. A study showed that systems with optimized actuation reduce response time by up to 30%. Yet, many overlook this aspect, risking inefficiency.

Reflection on usage conditions is essential. For instance, high-temperature environments may affect valve performance. Moreover, regular maintenance often gets neglected, leading to reduced lifespan. The perfect valve for one application might not work in another. This complexity requires careful consideration and ongoing evaluation. When selecting a hydraulic control valve, never underestimate the importance of type and actuation. They are key to a well-functioning system.