Leave Your Message

In modern fluid control systems, the **Butterfly Valve With Bypass** plays a significant role. According to a report by Markets and Markets, the global butterfly valve market is projected to grow to $8.39 billion by 2027. This growth indicates a rising demand for effective valve solutions across various industries. Bypass configurations allow for better control over flow rates, making them vital in applications requiring precision.

However, using a **Butterfly Valve With Bypass** effectively is not without challenges. Many operators miss crucial installation steps. This can lead to performance issues, such as improper sealing and flow disruption. Research shows that nearly 30% of valve failures stem from incorrect usage. It is essential to approach valve selection and maintenance thoughtfully.

Understanding your system’s requirements is critical. The right valve can enhance efficiency and reduce operational costs. Yet, it’s easy to overlook specific parameters. Failing to consider factors like temperature and pressure ratings can result in inadequate performance. This article will guide you through ten essential tips to optimize the usage of a **Butterfly Valve With Bypass** while avoiding common pitfalls.

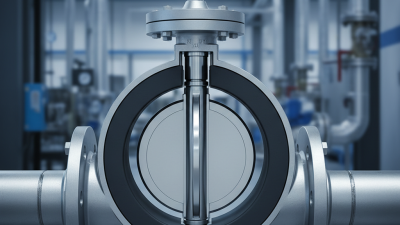

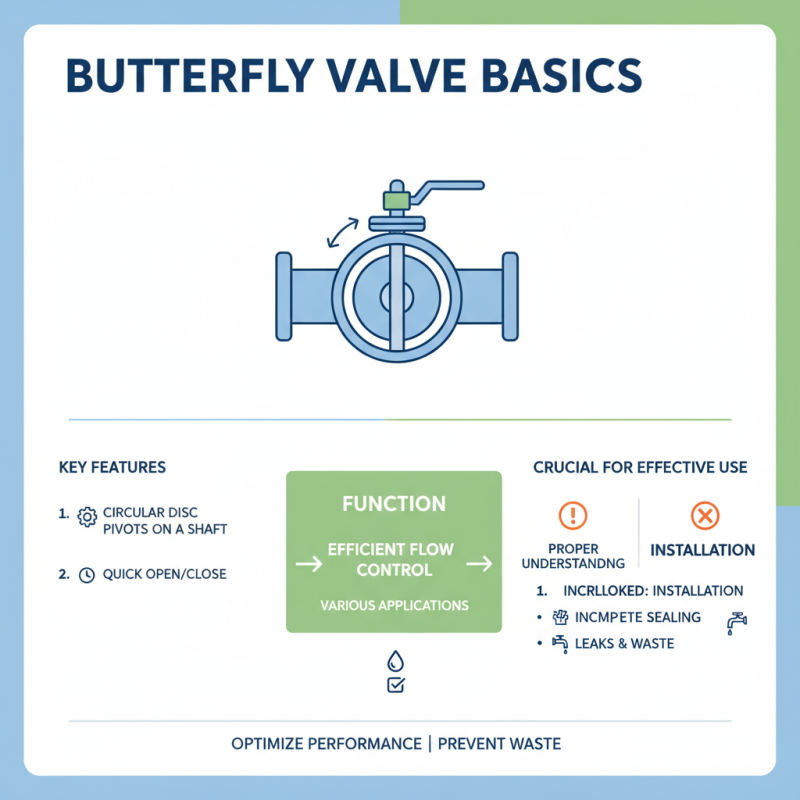

A butterfly valve features a circular disc that pivots on a shaft. This design allows for efficient flow control in various applications. The simplicity of the structure enables quick opening and closing. However, proper understanding is crucial for effective use. Many overlook the importance of installation, leading to incomplete sealing. This can cause leaks and waste.

The bypass feature plays a significant role. It allows for flow even when the valve is closed. Proper setup reduces pressure build-up, yet some users forget to adjust it. Fine-tuning is necessary for optimal performance. Monitoring the valve's position is also important. An improper angle can affect the system's efficiency.

Regular maintenance ensures longevity. People often neglect checking for wear and tear. This can lead to unexpected failures. Observing the valve's response during operation is key. Unusual noises or vibrations signal that something is wrong. Keep an eye on the overall system, not just the valve itself.

The integration of a bypass in butterfly valve operations offers significant benefits. A bypass allows for smooth flow even when the main valve is closed. This can minimize wear and tear on the valve components. According to a recent industry report, valves with bypass capabilities can enhance system efficiency by up to 30%. This is crucial in systems requiring precise control, like water treatment processes.

Effective usage of butterfly valves with a bypass involves strategic planning. Consider system requirements. Ensure that the bypass is correctly sized. An oversized bypass can lead to turbulence and inefficiency. Another tip is to monitor flow rates regularly. This helps in identifying any anomalies early, ensuring longevity.

Some data suggests that regular maintenance can extend a valve's lifespan by as much as 40%. A bypass can make maintenance procedures easier. It allows operators to isolate sections without interrupting flow. However, improper use of the bypass can cause unexpected pressure drops. This can lead to operational challenges. Balancing flow and pressure is essential.

This chart illustrates the effectiveness rating of 10 essential tips for utilizing a butterfly valve with a bypass efficiently. Each tip is rated on a scale from 1 to 10, indicating how well it contributes to effective valve operation.

Proper installation of butterfly valves with bypass requires attention to detail. Begin by choosing the right location. The valve should be accessible for maintenance. Ensure there is adequate space around it. This will make future adjustments easier.

Next, prepare the piping system. Clean the pipes and check for any defects. Align the butterfly valve with the pipes. Misalignment can lead to leaks or reduced efficiency. Tighten the bolts evenly to create a secure seal. Testing the valve after installation is crucial. Monitor for any unusual noises or leaks.

After installation, consider the bypass function. It allows for balance in flow and pressure. Sometimes, the bypass may need adjustment. This can improve system performance. Regular inspections will help identify potential issues. Don't underestimate the importance of documentation. Keep records of your installations and adjustments. This helps in future troubleshooting and maintenance.

Regular maintenance is crucial for butterfly valves with bypass features. These valves often handle varying pressures and flow rates. Over time, the seals can wear down, leading to leaks or reduced efficiency. Inspect seals for signs of wear and tear regularly. A simple visual check can save time and costs in the long run.

Incorporating proper lubrication into your routine is key. Using the right lubricants can prevent rust and ensure smooth operation. However, over-lubrication can attract dirt, leading to more problems. Always follow manufacturer guidelines for lubrication intervals. A checklist can help with this process.

Pay attention to any unusual noises during operation. Clicking or grinding sounds may indicate issues. It’s wise to investigate these promptly. Clean the valve regularly to prevent buildup. Build-up can cause sticking or slower response times. Find a balance where maintenance feels thorough yet manageable, as this improves the lifespan and performance of the valve significantly.

Bypass butterfly valves are essential in fluid control systems. However, they often face common issues that can disrupt performance. Regular maintenance is key. Frequent checks can prevent failures. For example, leaks around the valve seat commonly arise from wear and tear. A study by the Fluid Control Association highlights that over 30% of valve issues stem from poor maintenance practices.

Tip: Regularly inspect your butterfly valve for signs of wear. Look for unusual noises or vibrations during operation. These can indicate underlying problems. Addressing them early can save costs later.

Another frequent issue is the build-up of debris in the valve. This can lead to poor flow characteristics and affect efficiency. A survey by the American Society of Mechanical Engineers shows that a clean valve can improve flow rates by up to 20%.

Tip: Implement a routine cleaning schedule. Flushing the system periodically helps to ensure optimal performance and longevity of the valve. Be mindful of the type of fluids passing through the valve; they can contribute to corrosion over time.

Finally, calibration is essential. Incorrect calibration may lead to fluctuating pressures. This creates instability in the system. A report from the Valve Manufacturers Association indicates that proper calibration can enhance control and efficiency by up to 15%.

Tip: Regularly calibrate your bypass butterfly valve. Small adjustments can result in significant performance improvements.

| Tip Number | Tip | Common Issues | Troubleshooting Advice |

|---|---|---|---|

| 1 | Check Seals Regularly | Leakage | Inspect and replace worn seals. |

| 2 | Ensure Proper Alignment | Sticking or binding | Realign valve to prevent binding. |

| 3 | Monitor Operating Pressure | Inconsistent flow | Adjust operating pressure to recommended levels. |

| 4 | Use Correct Sizing | Flow restrictions | Select appropriate size for your application. |

| 5 | Regular Maintenance Schedule | Early wear and tear | Establish a routine maintenance plan. |

| 6 | Avoid Over-tightening | Damaged fasteners | Use torque wrench to prevent over-tightening. |

| 7 | Optimize Bypass Flow Rate | Increased wear | Adjust bypass settings for better performance. |

| 8 | Perform Regular Testing | Unknown malfunction | Conduct systematic tests to identify issues. |

| 9 | Educate Operators | Operator errors | Provide training on correct valve operation. |

| 10 | Consider Material Compatibility | Corrosion or degradation | Select materials compatible with media. |