Leave Your Message

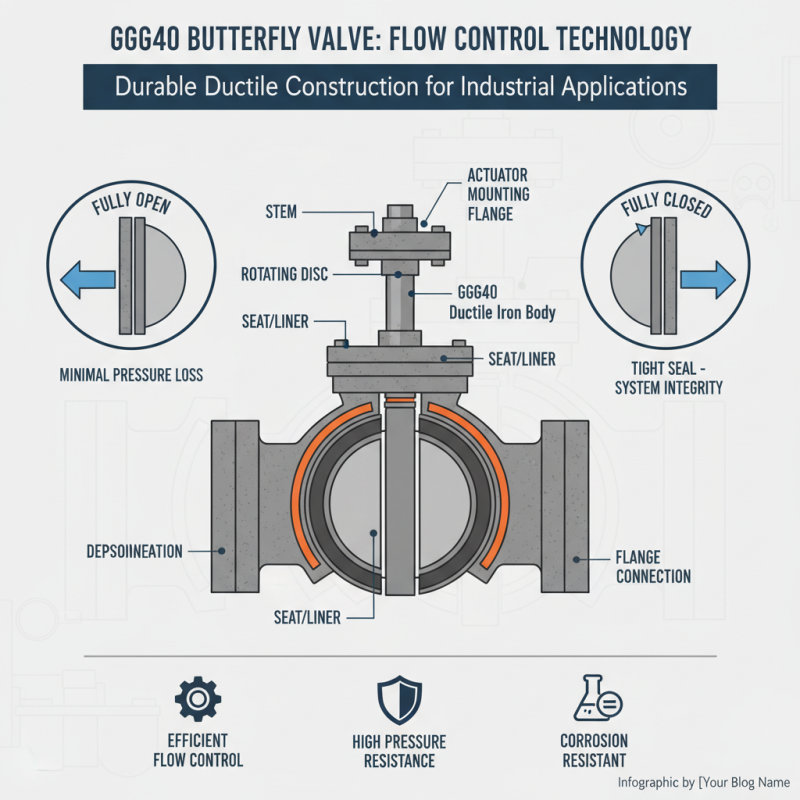

The Ggg40 Butterfly Valve is a critical component in various industrial applications, designed to regulate the flow of fluids with precision and efficiency. Characterized by its unique disc design, this valve operates by rotating the disc to open or close the flow pathway, allowing for quick adjustments to be made depending on system requirements. Understanding the mechanics and functionality of the Ggg40 Butterfly Valve is essential for engineers and operators within the industrial sector, where fluid control is vital for process reliability and safety.

In industrial environments, the Ggg40 Butterfly Valve demonstrates its versatility across a wide range of sectors, from water treatment facilities to chemical processing plants. Its lightweight construction and simple installation process make it a preferred choice for many applications. Moreover, the ability to easily maintain and repair these valves contributes to reduced downtime, enhancing productivity and efficiency. As industries move towards more automated systems, the role of the Ggg40 Butterfly Valve becomes increasingly pivotal, ensuring optimal performance in fluid management.

Overall, the Ggg40 Butterfly Valve not only exemplifies innovation in valve design but also highlights the importance of effective flow control in industrial processes. With its robust construction and reliable performance, this valve continues to be a trusted solution for professionals who demand precision and durability in their operations.

A GGG40 butterfly valve is a type of industrial valve used to regulate and control the flow of fluids in various pipes and systems. GGG40 refers to the specific gray cast iron material used in the construction of the valve, which offers excellent durability and resistance to environmental factors. This valve features a rotating disc or "butterfly" that is positioned in the center of the pipe. When the valve is turned, the disc rotates to either allow or restrict flow, making it an effective option for on-off and throttling applications within industrial settings.

The design of the GGG40 butterfly valve makes it particularly advantageous for applications requiring a lightweight yet sturdy solution. The valve's compact geometry ensures minimal pressure drop, which allows for efficient fluid dynamics. Additionally, the material's strength provides longevity in high-pressure and high-temperature environments. GGG40 butterfly valves are commonly employed in water treatment facilities, chemical processing plants, and HVAC systems, where reliable flow control is essential for operational efficiency. Their versatility and ease of maintenance further enhance their appeal in a wide range of industrial applications.

The Ggg40 butterfly valve is an essential component in various industrial applications, designed to regulate fluid flow through a pipeline effectively. Its structure primarily includes a disc, shaft, and body, each playing a crucial role in performance and durability. The disc, typically positioned at the center of the valve, rotates to open or close the flow path, allowing for quick adjustments and minimal pressure drop during operation. This design is ideal for applications requiring precise flow control and rapid response times.

The valve body, often made from high-strength materials, houses the disc and shaft while providing leak-tight sealing even under high-pressure conditions. The shaft connects the disc to the operator, which can be manual or automated, depending on the system requirements. Additionally, the Ggg40 butterfly valve is equipped with sealing mechanisms—often using elastomer materials—that enhance its tightness and longevity in operation. These key components work together to ensure the valve meets the demands of various industries, from water treatment to chemical processing, where reliability and efficiency are paramount.

This bar chart illustrates the performance metrics of the GGG40 Butterfly Valve in various industrial applications. The data points include flow rate, pressure drop, operational temperature, and yearly operational cost, highlighting the valve's efficiency and functionality within the industrial sector.

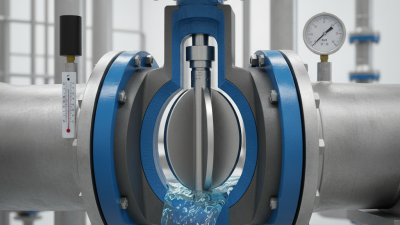

The GGG40 butterfly valve is a crucial component in various industrial applications due to its unique working principle that allows for efficient flow control. Constructed primarily from ductile iron, the GGG40 designation indicates its strength and durability, which is essential in environments where high pressures and corrosive conditions are prevalent. The core principle revolves around a disc that rotates within the valve body to either allow or restrict fluid flow. When the valve is fully open, the disc is positioned parallel to the flow, minimizing pressure loss and resistance. In contrast, when the valve is closed, the disc obstructs the flow path, providing a tight seal essential for maintaining system integrity.

In industrial settings, the GGG40 butterfly valve is often employed in applications such as water treatment, chemical processing, and power generation. According to a report by Future Market Insights, the global butterfly valve market is expected to grow at a CAGR of 4.8% from 2021 to 2031, driven largely by the increasing need for efficient flow regulation in various sectors. The GGG40 valve's design enables quick operation, with a 90-degree turn to transition between open and closed positions, significantly reducing lag time in operations. This efficiency is vital in maintaining the stability and safety of industrial processes, where even minor delays can lead to substantial operational risks or financial losses.

The Ggg40 butterfly valve is widely utilized across various industrial applications due to its efficiency and versatility in fluid control. Its cast iron construction provides durability, and its design allows for quick opening and closing, making it suitable for handling a range of fluids in sectors like water treatment, chemical processing, and HVAC systems. According to a report by Research and Markets, the global butterfly valve market is projected to reach approximately $7.2 billion by 2025, with a significant portion attributed to traditional industries that rely on Ggg40 valves for their operational needs.

In water treatment facilities, Ggg40 butterfly valves are essential for regulating water flow, ensuring both efficiency and safety. Their lightweight design allows for easy installation and maintenance, which is critical in environments where downtime can lead to costly interruptions. A study conducted by MarketsandMarkets indicates that the water treatment segment is expected to grow at a CAGR of 6.3% over the next few years, signifying a robust demand for effective flow control solutions like the Ggg40 butterfly valve. Similarly, in chemical manufacturing, these valves are preferred for their resistance to corrosion and ability to handle harsh chemicals, thus playing a vital role in maintaining process integrity and safety standards.

| Industry | Application | Valve Size (inches) | Temperature Range (°C) | Pressure Rating (psi) |

|---|---|---|---|---|

| Water Treatment | Flow Regulation | 2 | -10 to 80 | 150 |

| Chemical Processing | Isolation of Corrosive Fluids | 4 | -20 to 100 | 300 |

| Oil and Gas | Flow Control | 6 | -15 to 85 | 250 |

| HVAC | Dampers for Airflow | 8 | 0 to 70 | 125 |

| Food and Beverage | Handling of Liquid Products | 3 | -10 to 90 | 200 |

The Ggg40 butterfly valve is a widely used component in various industrial applications due to its unique design and functionality. This type of valve is crafted from Ggg40 ductile iron, providing excellent strength and durability. When considering the advantages of using a Ggg40 butterfly valve, one key benefit is its lightweight construction, which makes it easier to install and maintain compared to heavier valve types. Additionally, these valves offer a compact design that saves space within piping systems, making them ideal for environments where space is at a premium.

However, like any component, Ggg40 butterfly valves have their disadvantages. While they are efficient for throttling flow, they may not be suitable for heavy-duty applications where absolute tightness and control are critical. Furthermore, exposure to certain chemicals can lead to corrosion over time, potentially compromising the valve's integrity.

Tips: When choosing a Ggg40 butterfly valve for your application, ensure that you evaluate the compatibility of the material with the fluids being controlled, and consider the valve's pressure ratings to prevent operational issues. Regular maintenance is also vital to prolong the valve's lifespan, including occasional inspection for wear and tear.