Leave Your Message

In today's industrial landscape, the IP68 butterfly valve stands out for its robust design and superior functionality. Designed to withstand harsh environments, this valve can resist dust and water ingress, making it optimal for various applications. According to a report by Global Market Insights, the butterfly valve market is projected to reach $5 billion by 2027, emphasizing its rising importance.

Industry expert Dr. Alice Chang notes, “The IP68 butterfly valve offers a crucial advantage for sectors like oil and gas, where reliability is non-negotiable.” This valve operates by rotating a disc to control flow, providing quick shut-off capabilities. Its unique design minimizes pressure loss, enhancing efficiency.

However, not all installations meet the high standards expected of IP68 valves. It's important to consider installation best practices to avoid performance issues. Improper handling can lead to failures, undermining system integrity. The effectiveness of the IP68 butterfly valve hinges on correct application and maintenance, highlighting the need for industry professionals to prioritize operational standards.

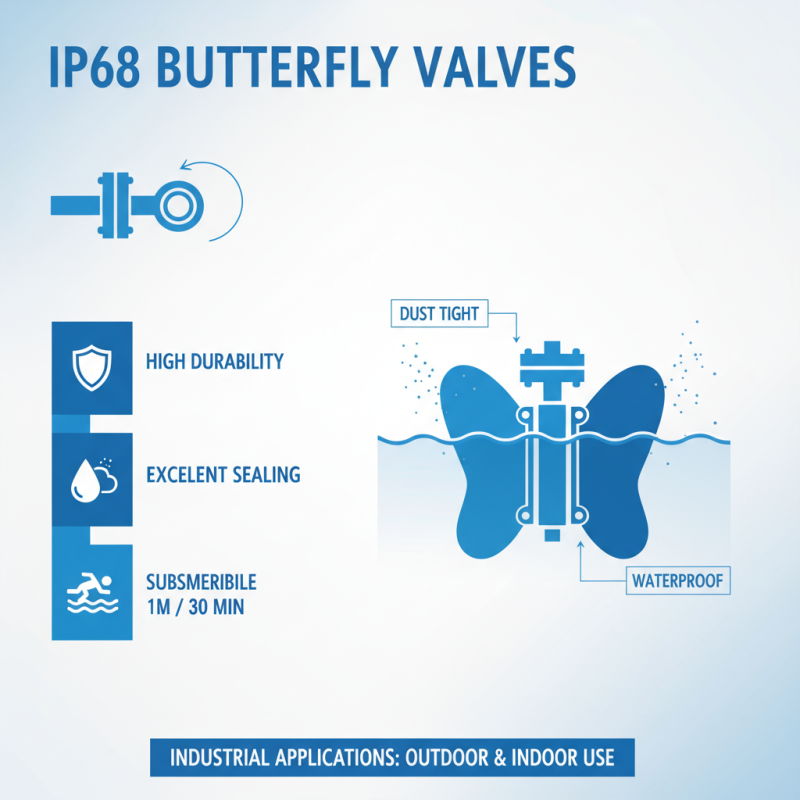

An IP68 butterfly valve is a type of valve that provides excellent sealing and durability. It is designed to withstand extreme conditions, making it suitable for various applications. The "IP" in its name stands for Ingress Protection. The "68" indicates that this valve is dust-tight and can be submerged in water. This means it can handle challenging environments without leaking.

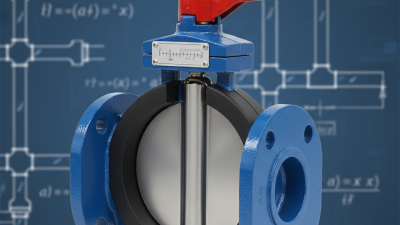

The butterfly valve operates using a circular disc that rotates on a shaft. When the valve opens, the disc turns away from the flow, allowing liquids or gases to pass. When closed, the disc blocks the flow completely, creating a tight seal. Its compact design allows for quick operation. However, achieving the perfect seal can sometimes be tricky. Dirt or debris can impact performance, making maintenance essential.

In environments prone to water and particulate intrusion, the IP68 valve excels. It keeps the flow system protected and operational. But, not every installation will be straightforward. Factors like temperature and pressure require careful consideration. Proper selection and installation are crucial for ensuring longevity. Regular inspections are equally important to avoid unexpected failures.

| Specification | Description |

|---|---|

| Type | Butterfly Valve |

| IP Rating | IP68 |

| Material | Stainless Steel, PVC, or Cast Iron |

| Size Range | 2 inches to 48 inches |

| End Connections | Wafer, Lug, and Flanged options |

| Working Pressure | Up to 16 bar |

| Temperature Range | -10°C to 80°C |

| Applications | Water treatment, HVAC, Food processing, Chemical applications |

| Operation | Manual, Electric, or Pneumatic actuator |

IP68 butterfly valves are essential components in various industrial applications. They are known for their high durability and excellent sealing capabilities. According to industry reports, these valves can withstand dust and immersion in water at depths of up to 1 meter for 30 minutes. This makes them ideal for both outdoor and indoor use.

One key feature of IP68 butterfly valves is their robust construction. They are commonly made from materials such as stainless steel or high-grade plastics. This ensures they resist corrosion and wear in challenging environments. Research indicates that these valves can operate effectively in temperatures ranging from -20°C to 80°C. However, operating limits may vary based on specific designs and materials used.

Another vital specification is their efficiency in flow control. The design allows for quick and easy actuation. Typical rotation for full closure is just a quarter turn, which is advantageous in emergency situations. Despite their robust design, regular maintenance is often overlooked, leading to potential performance issues. Industry studies have shown that neglecting routine inspections can reduce the lifespan of these valves significantly.

IP68 butterfly valves serve an important role in various industrial applications. These valves are designed to handle both low and high-pressure environments while providing exceptional sealing capabilities. The IP68 rating ensures protection against dust and continuous immersion in water. This makes them ideal for underground installations, marine applications, and harsh environmental conditions.

The mechanism of operation for IP68 butterfly valves is relatively straightforward. They utilize a rotating disc to control the flow of fluid. When the valve is closed, the disc seals tightly against the valve body, preventing any leakage. When open, the disc rotates parallel to the flow, minimizing resistance. This design allows for quick operation, often requiring only a quarter turn to open or close.

Tip: Regular maintenance is vital for optimal performance. Check seals and gaskets for wear and tear.

However, there are limitations. The performance of these valves can diminish if they are not sized correctly for the application. Oversized or undersized valves can lead to flow turbulence or insufficient pressure control.

Tip: Always consult pressure ratings and flow requirements before installation.

Ensuring that the valve operates within specified parameters is crucial. The valve's functionality can also be influenced by the media it controls. Corrosive substances may require additional considerations.

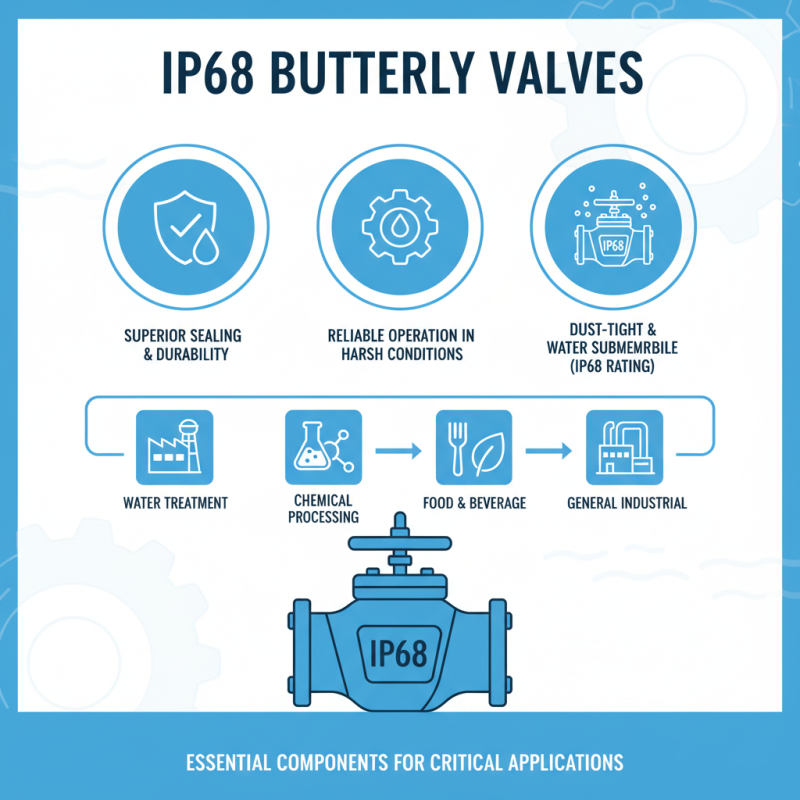

IP68 butterfly valves are essential components in various industries. They provide excellent sealing and reliable operation in harsh conditions. Their IP68 rating means they are dust-tight and can withstand submersion in water. This makes them ideal for applications in water treatment plants, chemical processing, and food industries.

In the water treatment sector, the demand for IP68 butterfly valves is growing. According to a recent market report, the global water and wastewater treatment market is expected to reach $750 billion by 2026. As infrastructure ages, the need for durable and effective valves becomes critical. The performance of these valves can significantly impact efficiency and maintenance costs.

In the chemical industry, these valves are used to control flow in corrosive environments. The report states that the chemical processing industry is projected to experience a CAGR of 4% up to 2030. This growth highlights the need for robust solutions that provide leak-proof sealing. However, maintenance remains a challenge. Many users report issues related to wear and tear, impacting their reliability. Addressing these concerns is essential for future applications.

Maintaining an IP68 butterfly valve requires careful attention. These valves are designed to withstand dust and water immersion. However, routine checks are essential. According to industry standards, regular inspections can prevent up to 30% of unexpected failures. This can lead to significant costs in repairs and downtime.

To start, check the sealing mechanism frequently. The IP68 rating means these valves offer high resistance. Yet, exposure to harsh chemicals can degrade seals over time. Inspecting for signs of wear, such as cracks or stiffness, is vital. Cleaning the valve regularly helps reduce residue buildup. Reports indicate that frequent cleaning can extend valve life by 20% or more.

Lubrication also plays a key role. Use the recommended lubricants that comply with the manufacturer’s guidelines. A well-lubricated valve operates smoothly and efficiently. However, over-lubrication can attract dirt, which complicates matters. Tracking performance is crucial. If a valve exhibits unusual resistance or noise, immediate attention is necessary. Such signs cannot be ignored, as they often indicate underlying issues.