Leave Your Message

The Pn16 Butterfly Valve is a crucial component in various industrial applications. Designed for efficient flow control, it is favored for its simple operation and compact design. Many industries, including water treatment and HVAC, rely on this valve for reliable performance.

One major benefit of the Pn16 Butterfly Valve is its versatility. It can handle different media types, like liquids and gases. This adaptability makes it a popular choice in multiple settings. However, not all applications suit its unique characteristics. It’s vital to understand the limitations and ensure appropriate usage.

When selecting a Pn16 Butterfly Valve, it’s important to consider specific requirements. Factors like pressure, temperature, and flow rate play a significant role. While these valves are efficient, they require careful integration into systems. Proper installation and maintenance are key to maximizing their functionality. Overall, the Pn16 Butterfly Valve offers reliability, but its effectiveness depends on thoughtful application.

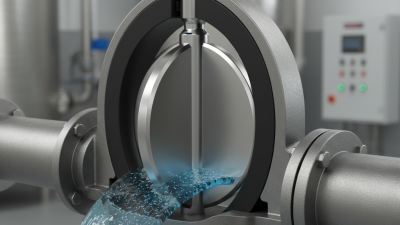

PN16 butterfly valves are essential in many industries. They operate under a pressure rating of up to 16 bar (PN16). These valves are designed to control the flow of liquids and gases efficiently. They feature a disc that rotates within the pipe. This simple design makes them reliable. However, the choice of materials can affect performance.

These valves are commonly used in water distribution, HVAC systems, and food processing. Their lightweight design allows for easy installation. They can handle various temperatures and fluid types. Installation is often straightforward, but proper sealing is crucial. If not correctly sealed, they may leak, leading to inefficiencies. Regular maintenance is vital to ensure longevity.

One of the benefits of PN16 butterfly valves is their cost-effectiveness. They consume less energy compared to other valve types. Their compact size requires less space, which is ideal in restricted areas. However, their operating range is sometimes limited. Choosing the wrong type of valve can result in inadequate performance. Understanding the specific application is key to making the right choice.

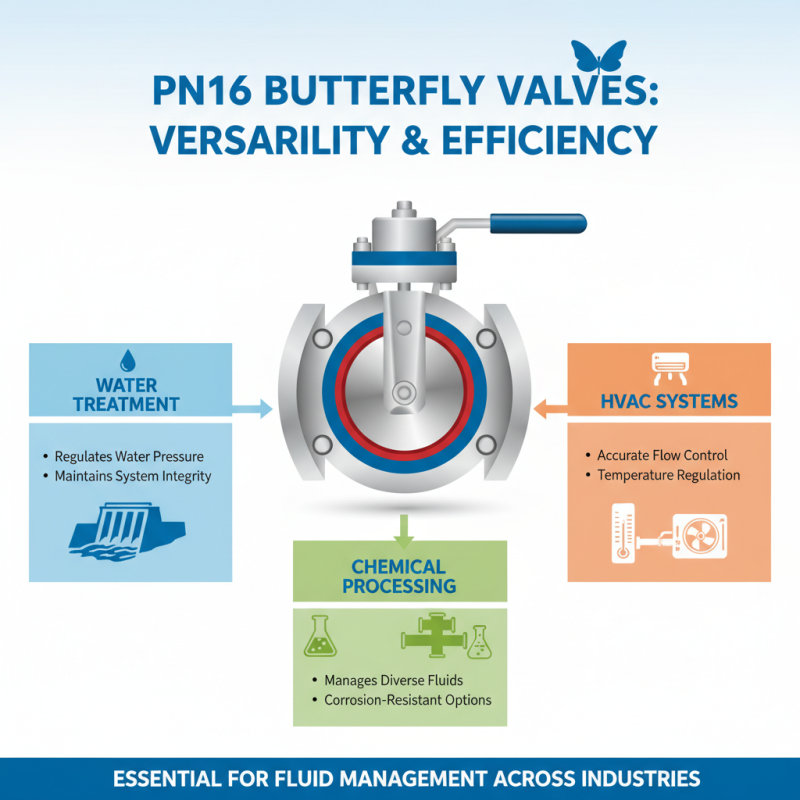

PN16 butterfly valves have gained popularity across various industries due to their versatility and efficiency. These valves are commonly used in water treatment plants, chemical processing, and HVAC systems. The ability to control flow accurately makes them essential in managing diverse fluids. In water treatment, for instance, they regulate water pressure effectively, which is crucial for maintaining system integrity.

In chemical processing, the durability of PN16 butterfly valves withstands harsh conditions. They often handle corrosive materials, which can be a challenge for other valve types. Yet, this application requires careful monitoring. Even a small failure can lead to significant issues. In HVAC systems, these valves help in controlling airflow. However, if not calibrated correctly, they may affect the overall system performance. It’s evident that while these valves are efficient, they also require ongoing maintenance and attention to ensure optimal function.

Industries benefit greatly from the reliability of PN16 butterfly valves. Yet, it’s essential to acknowledge that improper installation can lead to leaks or operational hiccups. Users must balance the advantages with the need for regular inspections. This approach can prevent costly repairs and improve overall system reliability. Although these challenges exist, the applications of PN16 butterfly valves continue to grow in various sectors.

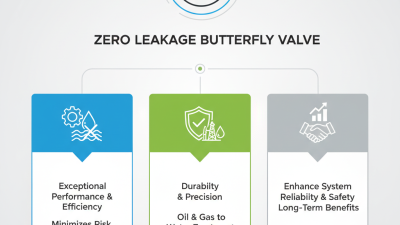

PN16 butterfly valves are vital in fluid control systems. They manage flow effectively in various industries, including water treatment and oil refining. These valves can handle pressures up to 16 bar, ensuring safety and reliability in operations.

One significant advantage of PN16 butterfly valves is their lightweight design. This feature allows for easier installation and maintenance. According to a recent industry report, companies can reduce installation time by up to 30% when switching to lighter valve solutions. However, some users report that this lighter weight can lead to concerns about durability under extreme conditions. Regular audits might be necessary to ensure long-term performance.

Additionally, these valves offer efficient flow management. They can provide quick shut-off and throttling capabilities. A study published in the Journal of Fluid Engineering indicates that butterfly valves can achieve up to 95% flow efficiency. Despite this efficiency, some users have noticed that the sealing may degrade over time, prompting the need for periodic inspections. Understanding these aspects helps optimize the use of PN16 butterfly valves in various applications.

When comparing PN16 butterfly valves with other valve types, some key differences emerge.

Butterfly valves are often lighter and more compact than gate or globe valves. This makes them easier to install, especially in tight spaces. Their design allows for quick opening and closing, which can be beneficial in many applications. However, they might not provide the same sealing ability as some other types.

Another aspect to consider is the flow characteristics.

Butterfly valves achieve a more streamlined flow, minimizing turbulence. This can lead to better efficiency in systems that handle liquids or gases. On the other hand, some users may find that color-coded indicators on other valve types offer clearer visual feedback for position status. This can pose challenges in high-speed operations where rapid adjustments are necessary.

It's also worth noting that while PN16 butterfly valves are cost-effective, their durability can be a concern in certain conditions.

Extreme temperatures and corrosive environments may impact their longevity. Users should evaluate their specific needs compared to alternatives like ball or check valves, especially where reliability is paramount. Each valve type has its own strengths and weaknesses, requiring careful consideration of operational demands.

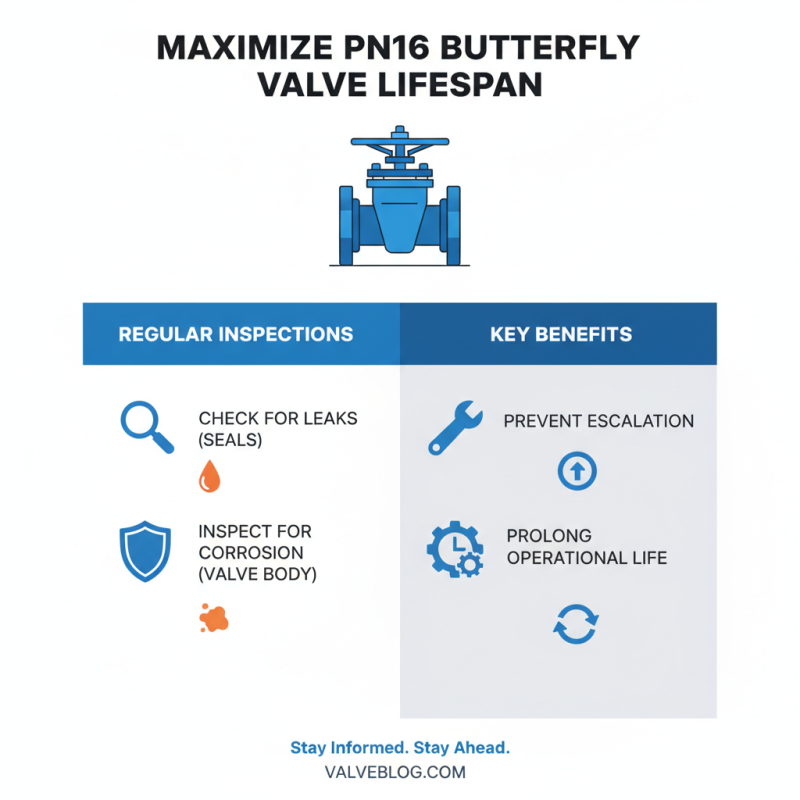

Maintaining PN16 butterfly valves is crucial for maximizing their lifespan. Regular inspections can identify issues before they escalate. Check for leaks, especially around the seals. These leaks can lead to more significant problems down the line. Inspect the valve body for corrosion, which can be surprisingly subtle. A small rust spot can compromise performance.

Lubrication plays a vital role. Use appropriate grease on the valve stem. This helps prevent wear and tear from friction. However, over-lubrication can attract dirt and debris. Finding a balance is key. Additionally, environment matters. High temperatures or corrosive materials can impact the valve’s integrity.

Don't forget about operational practices. Avoid closing or opening the valve too forcefully. This can cause unnecessary stress and damage. Training operators on proper usage can save costs long-term. It's not just about installation; ongoing care is essential for reliable performance. Regularly revisiting maintenance routines can lead to improvements and extend the life of PN16 butterfly valves.