Leave Your Message

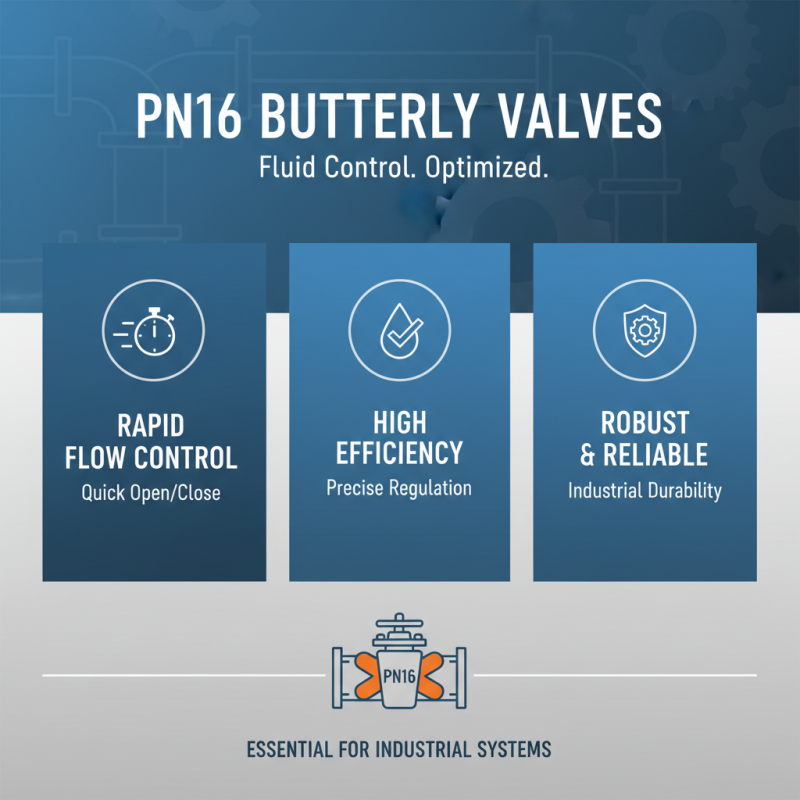

The Pn16 Butterfly Valve is a crucial component in various industrial applications, known for its efficient flow control and compact design. These valves operate by rotating a disc to regulate the flow of fluids through a pipe, offering a versatile solution for both on-off and throttling functions. Their ability to handle varying pressure conditions while maintaining durability makes them a staple in sectors such as water treatment, chemical processing, and HVAC systems.

Understanding how a Pn16 Butterfly Valve works is essential for engineers and operators looking to implement effective flow management strategies. The term "Pn16" refers to the valve's pressure rating, indicating its ability to withstand a maximum pressure of 16 bar, which is vital for ensuring system integrity and safety. This article delves into the mechanics of the Pn16 Butterfly Valve, exploring its components, operational principles, and the wide range of applications that benefit from its use. By mastering the functionality of these valves, professionals can enhance the performance and reliability of their fluid handling systems.

A PN16 butterfly valve is a type of valve characterized by a circular disc or vane that rotates within a pipe to control the flow of fluids. The "PN" designation indicates the valve's nominal pressure, with PN16 signifying a rating of 16 bar or approximately 232 psi. This classification implies that the valve is designed to withstand high-pressure environments while maintaining structural integrity, making it suitable for various applications in industries such as water treatment, oil and gas, and chemical processing.

The operation of a PN16 butterfly valve is straightforward. When the valve is in the closed position, the disc is perpendicular to the flow, blocking it effectively. Conversely, when the valve is opened, the disc rotates parallel to the flow direction, allowing for unrestricted passage of fluids. This design not only facilitates quick operation but also ensures a minimal pressure drop across the valve, making it an efficient choice for regulating flow. The simplicity of the butterfly valve's mechanism, combined with its robust pressure rating, allows for versatile application across different sectors, ranging from HVAC systems to larger industrial processes.

A PN16 butterfly valve is designed to operate efficiently in a variety of applications, thanks to its simple yet effective key components. The primary parts of a PN16 butterfly valve include the disc, body, stem, and actuator. The disc is the central component that rotates to open or close the valve. It is typically made of durable materials, ensuring long-lasting performance under high pressures. The valve body encases the disc and is designed to withstand the specified pressure ratings, which in the case of a PN16 valve, refers to a pressure limit of 16 bar.

The valve stem connects the disc to the actuator, enabling the rotation of the disc to control flow. This connection is critical for translating the actuator's motion into the desired valve function. Actuators can be manual, electric, or pneumatic, allowing for versatile operation depending on the application’s requirements. Additionally, seals are situated around the disc to prevent leakage when the valve is closed. Proper maintenance of these components is essential to ensure reliable performance and efficient operation in systems such as water treatment, chemical processing, and HVAC applications.

| Component | Material | Function | Typical Applications |

|---|---|---|---|

| Body | Cast Iron, Stainless Steel | Provides structure and houses internal components | Water Treatment, HVAC Systems |

| Disc | Ductile Iron, PVC | Controls flow by opening or closing | Chemical Processing, Food Industry |

| Seat | EPDM, NBR | Provides a seal to prevent leakage | Pumping Stations, Power Plants |

| Stem | Stainless Steel | Connects the actuator to the disc | Water Distribution, Irrigation |

| Actuator | Aluminum, Plastic | Controls the opening and closing of the valve | Automation, Remote Control Systems |

A PN16 butterfly valve is designed to handle various industrial applications efficiently, especially in systems requiring a durable and reliable flow control solution. Its operation is centered around the valve's disc, which rotates within the flow path to either allow or obstruct fluid movement. With a nominal pressure rating of 16 bar (PN16), this type of valve is particularly suitable for water, gas, and oil applications. According to the "Butterfly Valve Market Report" published by Research and Markets, the global butterfly valve market is projected to reach USD 9.54 billion by 2025, showcasing the increasing reliance on efficient fluid control mechanisms across various sectors.

In terms of operation, a PN16 butterfly valve employs a quarter-turn rotational motion, enabling rapid opening and closing capabilities. The disc is positioned in a perpendicular fashion to the flow when closed, providing a reliable seal. Conversely, when the valve is open, the disc aligns with the flow direction, allowing fluid to pass through with minimal resistance. This design is not only efficient but also reduces the power consumption needed to actuate the valve.

The Engineering ToolBox notes that butterfly valves can operate under various conditions, including high temperatures and pressures, making them versatile choices for both industrial and municipal applications. By choosing a PN16 butterfly valve, industries can enhance operational efficiency and reduce maintenance costs, reflecting a growing trend toward sustainable and cost-effective operational practices.

PN16 butterfly valves are essential components in various industrial applications due to their efficiency and reliability in regulating flow. These valves are designed to operate under a nominal pressure of 16 bar, making them suitable for diverse settings, such as water treatment plants, chemical processing, and HVAC systems. Their simple yet effective mechanism allows for quick opening and closing with minimal torque, which is beneficial in operations that require swift responses to flow changes.

In industrial sectors, the applications of PN16 butterfly valves are wide-ranging. They are commonly used in pipelines for controlling the flow of liquids and gases, where their lightweight design permits easy installation and maintenance. Additionally, these valves are ideal for throttling applications, allowing operators to manage flow rates with precision. In wastewater treatment facilities, PN16 butterfly valves play a critical role in controlling the flow of waste and chemicals, ensuring efficient processing and compliance with environmental regulations. Their versatility makes them particularly advantageous in sectors requiring robust and durable valve solutions.

PN16 butterfly valves are an essential component in various industrial systems, offering numerous benefits that make them a popular choice for fluid control applications. One of the primary advantages of using PN16 butterfly valves is their ability to provide quick and efficient control over flow rates. Their design allows for rapid opening and closing, which is crucial in applications where managing flow is essential to operational efficiency.

Another significant benefit of PN16 butterfly valves is their lightweight and compact design, which simplifies installation and maintenance. These valves can be easily integrated into existing piping systems without the need for extensive modifications. Additionally, their low torque requirement means that they can be operated using smaller actuators, reducing energy consumption and overall operating costs. This efficiency not only contributes to improved system performance but also supports sustainable practices in various industries.

Furthermore, the versatility of PN16 butterfly valves makes them suitable for a wide range of fluids, including water, gas, and various chemicals. This adaptability enables their use in diverse applications such as water treatment, HVAC systems, and chemical processing, ensuring reliable performance across multiple scenarios. Overall, the benefits of using PN16 butterfly valves significantly enhance the operational capabilities of fluid control systems, promoting efficiency and reliability.