Leave Your Message

The Pn25 Butterfly Valve is essential in various industrial applications. Utilized for its durability and efficiency, this valve can handle high-pressure systems up to 25 bar. According to a recent industry report, the demand for butterfly valves is projected to grow by 5% annually. This growth reflects their versatility in fluid control.

Engineered for reliability, the Pn25 Butterfly Valve provides excellent sealing properties. Its design allows for quick opening and closing, reducing operational delays. However, some may overlook proper maintenance. Regular checks are crucial to prevent wear and tear. Neglecting this need can lead to failures in the field.

Understanding the Pn25 Butterfly Valve's operation helps minimize risks. This valve's unique structure enables smooth flow regulation. Yet, not all users grasp its complexities. Training and awareness are necessary to maximize performance. Investing in education can significantly enhance efficiency in industrial settings.

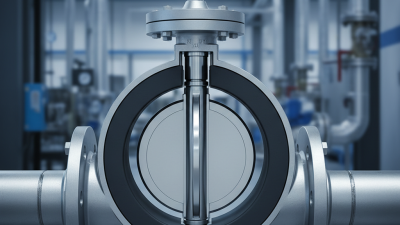

A Pn25 butterfly valve is a widely used component in fluid control systems. It operates by using a rotating disc, which adjusts the flow of liquid or gas. This valve can handle a pressure rating of up to 25 bar, making it suitable for high-pressure applications. Its design is simple yet effective, allowing for rapid opening and closing. Many industries rely on it for efficient flow control.

When choosing a butterfly valve, consider the material. Common materials include cast iron, stainless steel, and plastic. Each material has its strengths and weaknesses. For instance, cast iron is durable but may corrode over time. Stainless steel offers improved corrosion resistance but can be costlier. It's essential to match the valve's material to the specific environment it will operate in.

Tips for installation include ensuring proper alignment during setup. Misalignment can lead to premature wear. Regular maintenance is crucial to prolong the life of the valve. Inspect seals and hinges for any signs of damage. Keep the valve clean to avoid buildup that may affect performance. Always follow the manufacturer's guidelines for the best results.

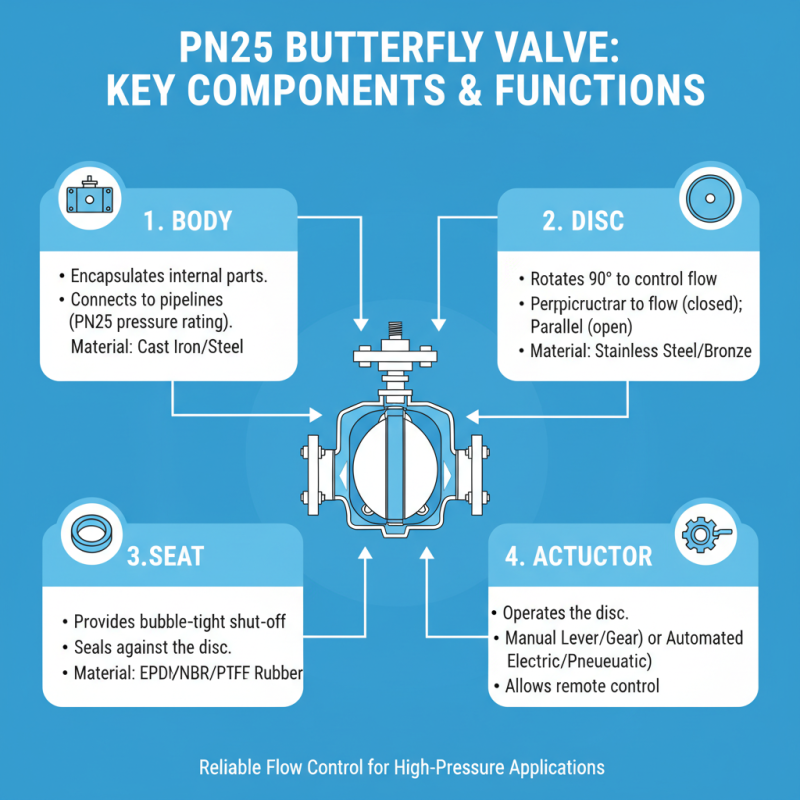

A Pn25 butterfly valve is essential in various industrial applications. Its design is simple yet effective for regulating flow. The key components of a Pn25 butterfly valve include the body, disc, seat, and actuator. Each part plays a crucial role in the valve's performance.

The body is typically made from materials like cast iron or stainless steel. This ensures durability and corrosion resistance. The disc is the main controlling element, and its circular shape allows for smooth flow transition. The seat is vital for creating a seal, preventing leaks. It is often made from elastomeric materials, which provide flexibility and resilience.

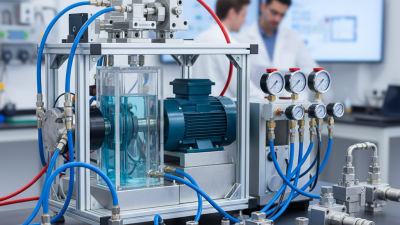

Actuators can be manual or automated. Recent reports highlight that automated butterfly valves improve operational efficiency by 25%. However, improper actuator selection can lead to performance issues. The assembly also requires regular maintenance checks to meet industry standards. Each component must work in harmony for effective flow control. Attention to these details can prevent costly downtime and ensure system reliability.

A Pn25 butterfly valve is a crucial component in various piping systems. It works by using a rotating disc to regulate flow. When the disc is parallel to the flow, it allows maximum flow. Conversely, turning the disc perpendicular restricts flow. This simple mechanism makes it effective and efficient.

The operation of a Pn25 butterfly valve is typically managed by a handle or an actuator. The handle allows manual control, which can be useful in smaller applications. Using an actuator enables remote control for larger systems, enhancing operational flexibility. The valve's design ensures quick opening and closing, making it ideal for tasks requiring rapid flow adjustments.

Tips for maintaining a Pn25 butterfly valve include regular inspections. Look for signs of wear or corrosion. Keep the valve clean to ensure smooth operation. It’s also essential to check the seal periodically to prevent leaks. Noticing small issues early can prevent bigger problems later. Always refer to operating guidelines when making adjustments.

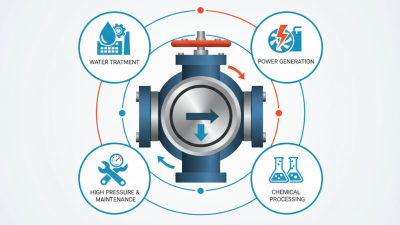

The Pn25 butterfly valve is widely used across various industries due to its ability to handle high pressure and flow rates. In sectors such as water treatment, chemical processing, and HVAC systems, these valves are essential for regulating fluid flow. The valve's design allows for quick and efficient opening and closing, making it ideal for applications where precision is crucial. According to industry reports, the demand for such valves is projected to grow by 5% annually, driven by increased industrial activities.

In chemical processing plants, Pn25 butterfly valves are favored for their reliability and low maintenance requirements. They can withstand corrosive materials, ensuring safety and longevity. The application extends to power generation, where these valves help control steam and coolant flow. This versatility reflects a trend toward automation and improved efficiency in industrial systems. However, it is worth noting that installation mistakes can lead to improper sealing, causing leaks and inefficiencies.

Tips: Always perform regular maintenance checks on your butterfly valves. This ensures optimal performance and extends their lifespan. Additionally, proper training for staff handling these valves is necessary to prevent operational errors. Some users overlook simple installation guidelines, which can prove costly in the long run. Remember, even minor adjustments can significantly impact efficiency.

The Pn25 butterfly valve is widely utilized across various industries, showcasing its significant applications in sectors such as water treatment, oil & gas, chemical processing, food & beverage, and HVAC systems. This chart visually represents the number of applications for Pn25 butterfly valves in these industries.

Pn25 butterfly valves are widely used in various industries for controlling fluid flow. They offer several advantages. First, their lightweight design allows for easy installation and reduces structural load. According to a recent industry report, these valves can save up to 30% in installation costs compared to heavier valve types. They are also known for their quick operation. A 90-degree rotation can fully open or close the valve, minimizing downtime.

However, Pn25 butterfly valves have drawbacks. For example, they may not be as effective for throttling applications. In high-pressure scenarios, flow regulation can become less precise. According to research, performance can decrease significantly under such conditions. Additionally, their sealing capabilities might not match those of other valve types. This can lead to leaks. Regular maintenance is required to avoid such issues, which adds to overall operational costs. Users should weigh these factors carefully when choosing Pn25 butterfly valves for their systems.