Leave Your Message

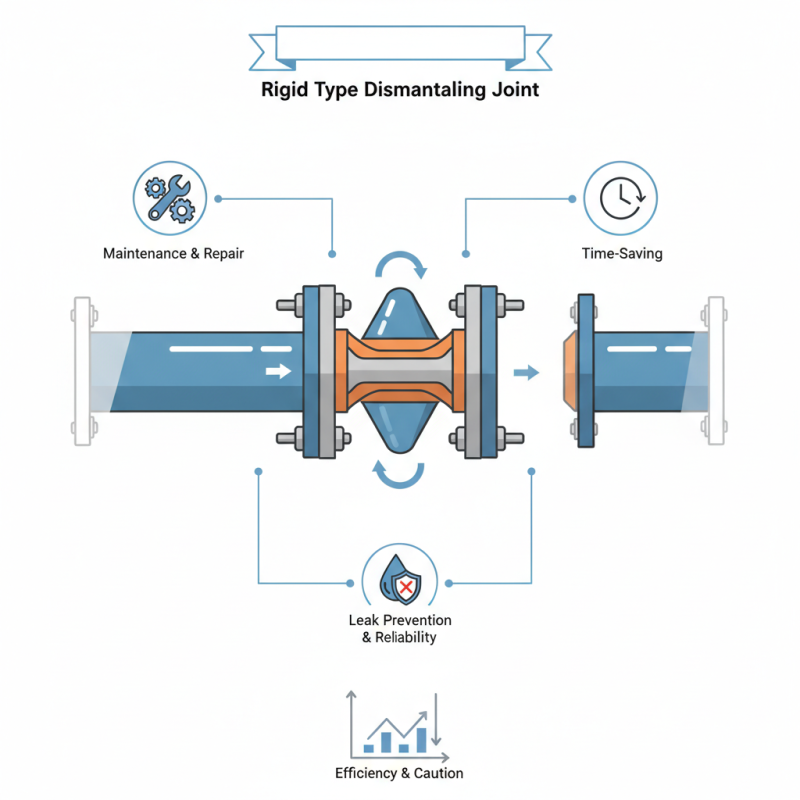

The Rigid Type Dismantling Joint is an essential component in modern piping systems. It allows for the disassembly of pipes without damaging their structural integrity. This joint design is particularly useful in maintenance and repair scenarios.

In any industrial setup, the ability to easily dismantle and reassemble components is crucial. The Rigid Type Dismantling Joint elegantly addresses this need. It provides a reliable seal while ensuring that parts can be accessed without extensive labor. This feature saves time and reduces downtime, which is invaluable.

Yet, not all joints are foolproof. Some may experience wear over time, leading to potential leaks. Understanding these risks is vital for effective maintenance. The Rigid Type Dismantling Joint represents a balance between functionality and caution. Users must reflect on how these joints perform in their specific applications to ensure long-lasting efficiency.

A rigid type dismantling joint is a sophisticated mechanical component used in various piping systems. Its primary function is to allow for easy maintenance and disassembly without compromising the system's integrity. These joints can handle high-pressure scenarios and provide stability, making them essential in industries like oil and gas, water treatment, and HVAC.

Industry reports indicate that about 30% of maintenance costs in piping systems stem from difficulties in dismantling joints. This highlights the need for reliable solutions. Rigid type dismantling joints streamline these operations. They are designed for repeated assembly and disassembly, reducing labor time and minimizing risks of damage during maintenance.

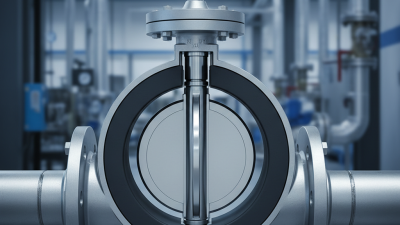

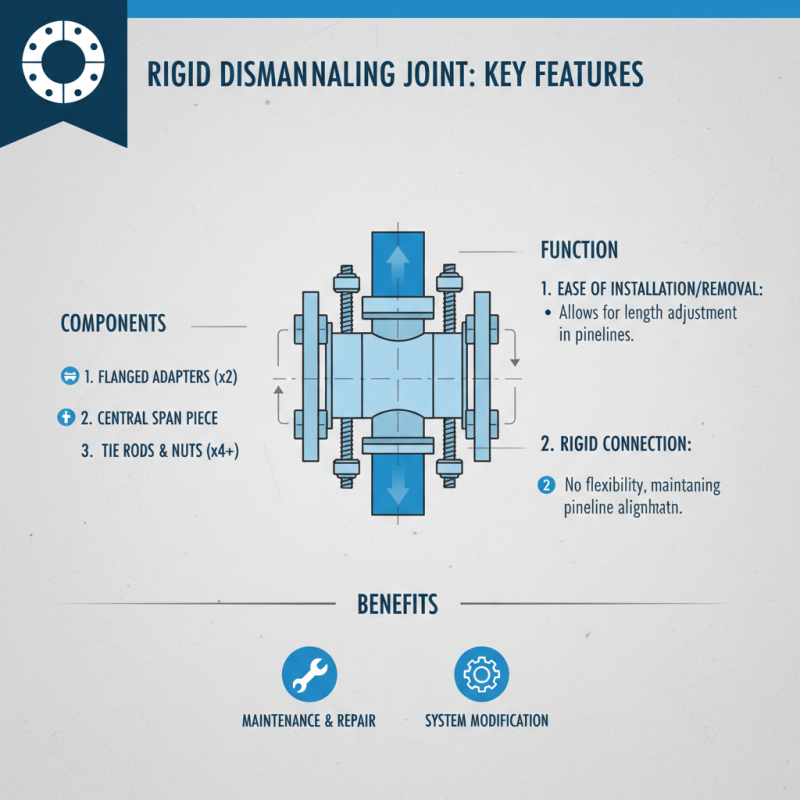

A rigid type dismantling joint is an essential component in piping systems. It allows easy access for repairs and maintenance. Understanding its key components helps in grasping its functionality.

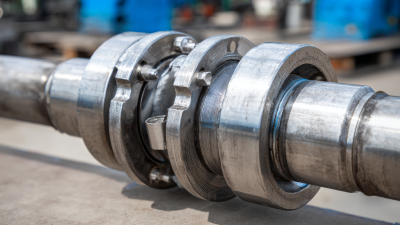

The main elements of a rigid dismantling joint include flanges, bolts, and a flexible gasket. Flanges are used to connect the joint to other pipe sections. They provide a stable interface. Bolts secure the joint tightly, ensuring no leakage occurs. A flexible gasket creates a seal between flanges. It accommodates minor misalignments during installation.

Another integral part is the body of the joint. This often has a cylindrical shape. It provides the necessary strength and rigidity. However, it must be noted that improper installation can lead to complications. Misalignment can cause stress on the joint. Attention to detail during assembly is critical. If flanges are not aligned properly, it may result in leaks over time.

A rigid type dismantling joint is an essential component in piping systems. It allows for easy disassembly and maintenance of pipelines. These joints are designed to withstand high pressures while providing stability and strength. Their structure involves a rigid connection, preventing misalignment during operation.

The functioning of a rigid type dismantling joint is straightforward. It utilizes a combination of bolts and gaskets to create a leak-proof seal. When disassembly is needed, the bolts are simply removed. This process is often quicker than expected, yet can feel daunting for inexperienced workers. Care must be taken, as improper handling may lead to damage.

In actual application, installations may not always go as planned. Sometimes, fittings are misaligned or bolts are over-tightened. Regular inspections are crucial to identify potential issues early on. While these components are reliable, they require attentive maintenance. Awareness of their limitations can prevent costly downtimes.

Rigid type dismantling joints play a crucial role in various industries. They are essential in systems that require regular maintenance. These joints allow for easy disassembly without damaging connected components. Industries such as water supply, wastewater treatment, and plumbing benefit from this feature. They help reduce downtime during maintenance work. The ability to detach pipes quickly facilitates repairs and upgrades.

In construction, rigid dismantling joints ensure seamless connections in piping systems. They maintain the integrity of the system while allowing for flexibility in design. During installation, these joints should be carefully aligned. Misalignment can lead to leaks or increased wear on materials. They can be used in extreme conditions like high pressure or temperature, yet their effectiveness depends on proper installation.

Moreover, the presence of rigid dismantling joints enhances safety in industrial applications. They ensure secure connections, minimizing the risk of spills or failures. However, mistakes in installation can have serious consequences. Regular inspections help identify wear and prevent potential issues. The balance between durability and maintenance ease is crucial in their application.

Rigid type dismantling joints are essential in construction. They provide critical benefits that enhance both efficiency and safety. These joints allow for easy disassembly of piping systems without damaging adjacent components. Their design enables seamless transitions between different pipe sizes and materials. This makes installation straightforward and minimizes potential leaks.

One significant advantage is that they promote better maintenance access. When repairs are necessary, these joints simplify the process. Workers can quickly dismantle and reassemble piping systems, saving valuable time. However, improper assembly or installation can lead to complications. Ensuring proper alignment is key to their effectiveness.

Additionally, rigid dismantling joints improve structural stability. They can withstand high pressure, making them ideal for demanding applications. Yet, it's crucial to regularly inspect these joints for wear and tear. Failure to do so might result in unexpected failures. Balancing ease of use with regular maintenance is vital for optimal performance.