Leave Your Message

In the realm of modern engineering, the integration of innovative solutions has transformed the construction and maintenance of various infrastructures. One prominent advancement is the Rigid Type Dismantling Joint, a component that has significantly enhanced the efficiency of piping systems. According to Dr. Emily Carter, a leading expert in industrial joint technology,

“The use of Rigid Type Dismantling Joints not only facilitates easier maintenance but also ensures the structural integrity of piping systems during dismantling processes.” This statement encapsulates the essential role that these joints play in ensuring operational reliability.

As industries continue to expand and face challenges such as aging infrastructure and the need for rapid upgrades, the demand for effective solutions like the Rigid Type Dismantling Joint has surged. In this comprehensive guide, we will explore the top five applications and benefits of these joints. By delving into their various uses across industries, we can better appreciate how they contribute to enhanced performance, reduced downtime, and improved safety measures. Through expert insights and practical examples, this guide aims to shed light on the critical importance of Rigid Type Dismantling Joints in contemporary engineering practices.

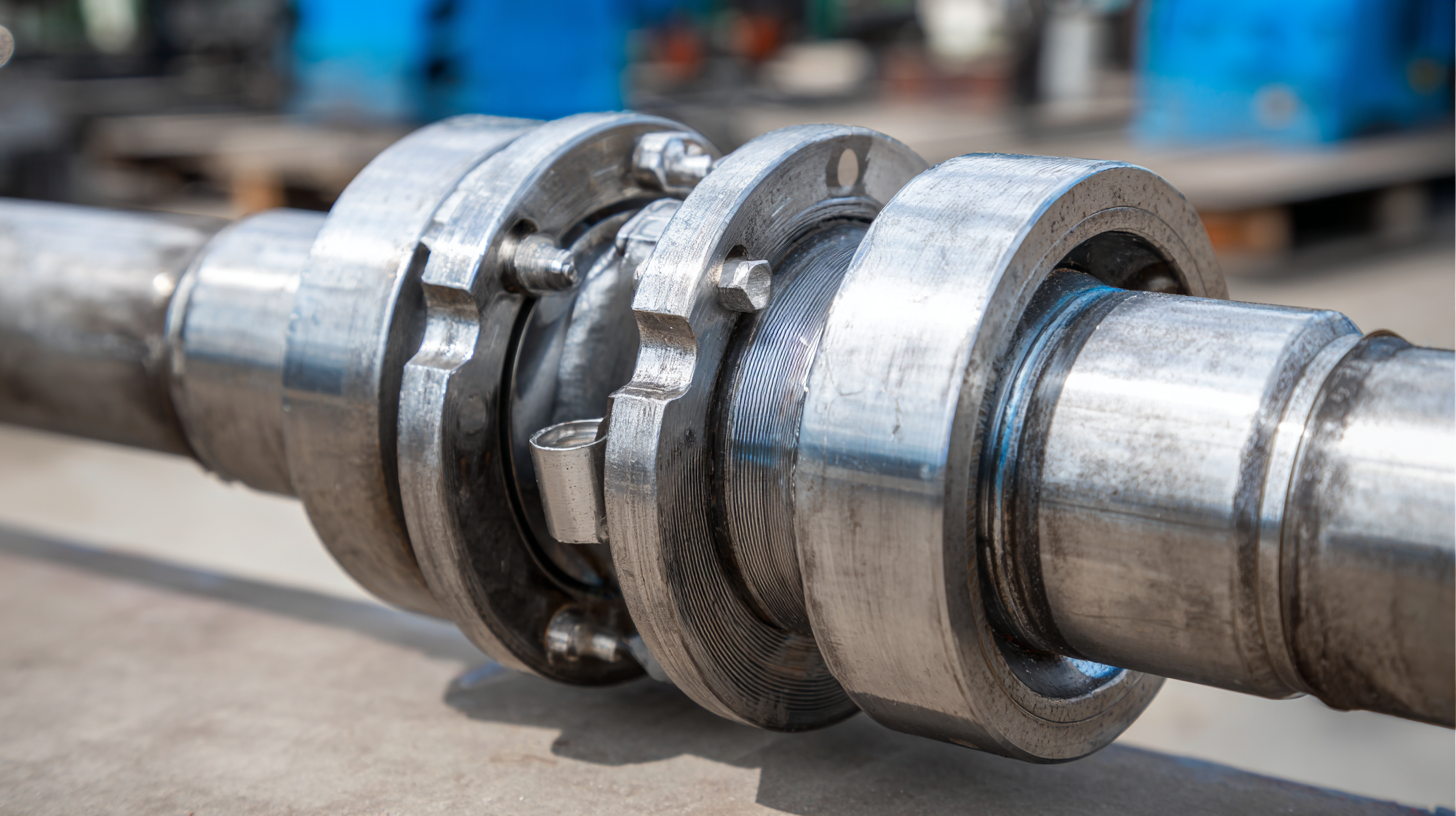

Rigid type dismantling joints, often referred to as rigid couplings, serve a critical function in various piping systems. Their primary role is to connect two sections of pipe in a manner that allows for the transmission of load without misalignment or displacement. According to a report from Global Industry Analysts, the rigid couplings market is projected to grow significantly, driven by the increasing demand for durable and reliable piping systems in industries such as oil and gas, water treatment, and construction.

Functionality-wise, rigid type dismantling joints are designed to facilitate maintenance and inspection by allowing engineers to easily disassemble and reassemble pipe sections without the need for special tools or extensive downtime. A study published in the Journal of Pipeline Engineering highlighted that the use of these joints can reduce maintenance costs by up to 30% in large-scale industrial applications. Furthermore, the precision engineering behind these fittings ensures minimal leakage and structural integrity, making them indispensable for high-pressure environments. The adoption of advanced materials and technologies in their manufacturing further enhances their performance and lifespan, positioning them as a preferred choice for modern infrastructure projects.

Rigid type dismantling joints play a critical role in various industries, providing

structural integrity and ease of handling during maintenance and repairs.

In the aerospace and defense sectors, the utilization of rigid dismantling joints is

essential for ensuring reliable connections in complex systems.

The U.S. and U.K. Aerospace and Defense PCB market, which includes rigid PCBs, is

projected to grow significantly, reflecting a robust demand for advanced electronics in military and commercial applications.

According to recent industry analyses, the market is valued multi-billion dollars

and is expected to experience a steady compound annual growth rate, indicating a sustainable reliance on components that enhance

system performance.

Rigid type dismantling joints play a critical role in various industries, providing

structural integrity and ease of handling during maintenance and repairs.

In the aerospace and defense sectors, the utilization of rigid dismantling joints is

essential for ensuring reliable connections in complex systems.

The U.S. and U.K. Aerospace and Defense PCB market, which includes rigid PCBs, is

projected to grow significantly, reflecting a robust demand for advanced electronics in military and commercial applications.

According to recent industry analyses, the market is valued multi-billion dollars

and is expected to experience a steady compound annual growth rate, indicating a sustainable reliance on components that enhance

system performance.

In the industrial sector, rigid type dismantling joints are equally important, facilitating

quick assembly and disassembly of machinery.

The Industrial Fasteners Market, too, demonstrates growth, with a marked increase in demand for metal-based fasteners that complement

rigid dismantling joints. This market segment is expected to expand as industries seek solutions that improve

efficiency in assembly processes. Furthermore, in the burgeoning field of plastic packaging,

rigid plastic packaging types are forecasted to maintain a significant market share, driven by their

durability and versatility. As industries evolve, the strategic application of

rigid type dismantling joints becomes increasingly vital for maintaining operational efficiency across various sectors.

Rigid type dismantling joints are increasingly popular in various industries due to their numerous advantages for maintenance and repair. These joints enable quick disassembly, allowing for efficient access to pipelines and equipment without the need for extensive removal processes. This not only saves time but also reduces the labor costs associated with maintenance activities. Their robust design ensures that they can withstand high pressures and temperatures, making them ideal for critical applications such as in power plants and chemical processing facilities.

Tips for choosing the right rigid type dismantling joint include assessing the specific requirements of your system. Consider factors such as the working pressure, temperature, and the type of fluid or gas being transported. Additionally, ensure proper alignment during installation to prevent stress on the joint, which can lead to premature failure. Regular inspections can also help identify any signs of wear or damage, allowing for proactive maintenance before a joint fails.

Incorporating rigid type dismantling joints into your maintenance regime not only streamlines operations but also enhances safety. By facilitating easier access to vital components, these joints minimize downtime and improve overall system reliability. Be sure to train your maintenance staff on the best practices for using these joints to maximize their benefits.

When considering dismantling joints in piping systems, there is an ongoing debate between rigid and flexible designs. Rigid dismantling joints are engineered to provide a sturdy, fixed connection that can enhance system stability and support heavy loads. According to a recent industry report from the Global Pipeline Joint Market Analysis, rigid joints have seen a 15% increase in demand over the last three years, primarily due to their applications in critical infrastructure and large-scale industrial systems. This rising preference can be attributed to their ability to withstand high pressures and mechanical stress, making them ideal for environments such as oil and gas pipelines.

In contrast, flexible dismantling joints offer the advantage of accommodating movement and thermal expansion within the pipeline. They allow for easier alignment adjustments and maintenance without needing to realign or replace entire sections of the piping system. A survey conducted by the International Institute of Piping Engineering revealed that a significant 40% of engineers prefer flexible designs for their ability to minimize installation time and costs, especially in retrofit projects. However, when evaluating long-term performance under heavy-duty conditions, the rigidity of rigid dismantling joints often proves to be a more reliable choice, underscoring the importance of carefully assessing the specific application needs before making a selection.

When it comes to installing rigid type dismantling joints, following best practices is crucial for ensuring functionality and durability. The first step is to ensure that all components are clean and free of debris before assembly. This prevents misalignment and promotes a tighter seal, which is essential for maintaining pressure in piping systems. Additionally, verifying that the flanges are aligned correctly will minimize the risk of leaks and ensure optimal performance.

**Tip:** Always use a torque wrench to secure bolts evenly. This helps to apply uniform pressure across the joint, reducing the likelihood of failure caused by uneven stress distribution.

Proper lubrication of the sealing surfaces is also key. Using suitable lubricant can aid in achieving a better seal and making future disassembly easier. It's important to choose a lubricant compatible with the materials involved to avoid degradation. Keep in mind that re-checking the joint integrity after a specific operational period can further enhance the longevity of the installation.

**Tip:** Incorporate regular maintenance schedules to inspect the joints for wear and tear, ensuring any issues are addressed before they escalate.

| Application Area | Benefits | Installation Best Practices |

|---|---|---|

| Water Supply Systems | Enhanced flow control and maintenance convenience | Ensure proper alignment and use appropriate sealing techniques |

| Wastewater Management | Improved accessibility for inspections and repairs | Follow manufacturer's guidelines for torque specifications |

| Industrial Applications | Durability and resistance to high pressure | Use protective coatings to prevent corrosion |

| HVAC Systems | Minimized vibration and noise during operation | Install with proper supports to ensure stability |

| Fire Protection Systems | Reliable performance under extreme conditions | Regularly inspect joints for wear and damage |