Leave Your Message

The Rubber Seat Butterfly Valve is a critical component in various industries. These valves feature a unique design that allows for efficient flow control. Their lightweight structure is beneficial for easy installation and maintenance.

One of the main advantages of the Rubber Seat Butterfly Valve is its durability. The rubber seat provides an effective seal, preventing leaks. This characteristic makes it suitable for both low and high-pressure applications. Many industries rely on its versatility.

However, not all applications may benefit from this type of valve. In some extreme conditions, the rubber seat may degrade over time. This can lead to performance issues. Users should carefully evaluate their specific requirements before choosing this valve. Understanding both its advantages and potential limitations is essential for optimal performance.

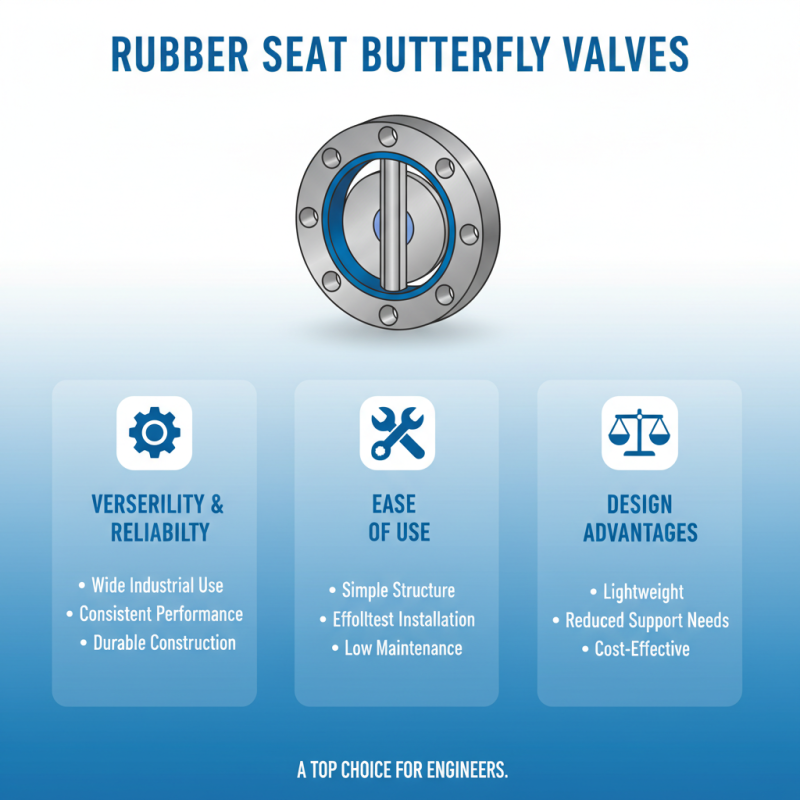

Rubber seat butterfly valves are known for their versatility and reliability in various industrial applications. Their key features make them a popular choice among engineers. These valves typically have a simple structure. This contributes to their ease of installation and maintenance. They are also lightweight, reducing support structure requirements.

One significant advantage of rubber seat butterfly valves is their ability to handle different fluids. This includes water, oil, and gases. Their soft rubber seats provide excellent sealing. This feature leads to minimal leakage and lowers energy costs. According to industry reports, these valves can achieve up to 90% efficiency in certain applications. This efficiency is crucial for industries that prioritize low operational costs.

Tip: Always consider the specific application when selecting a valve. The correct size and type can significantly impact performance.

However, the longevity of these valves can sometimes be a concern. Rubber materials may degrade over time, especially in harsh environments. Regular inspections are essential. They can help identify wear and tear before it leads to failure. Also, take note of the temperature and pressure ratings for optimal performance.

Tip: Replace seals at recommended intervals. This can prevent leaks and extend valve life.

Rubber seat butterfly valves offer several advantages that make them a popular choice in various industries. One significant benefit is their reliability in sealing. The rubber seat forms a tight seal, preventing leaks even under high-pressure conditions. This feature is crucial in fluid handling applications. Users often appreciate the low maintenance requirements associated with these valves. Over time, lesser upkeep leads to cost savings.

Another notable aspect is their versatility. These valves can handle different media, including water, chemicals, and slurries. Additionally, they are lightweight, making installation easier and more efficient. This ease of use is vital in both new setups and retrofitting projects. However, attention must be given to the temperature limits of rubber. Extreme conditions can affect performance.

While the advantages are compelling, it is important to regularly check for wear. Rubber material can degrade over time. Users might overlook this aspect, leading to unexpected failures. Maintaining a schedule for inspections can mitigate such risks. Ultimately, recognizing both strengths and potential shortcomings will help in achieving optimal performance with rubber seat butterfly valves.

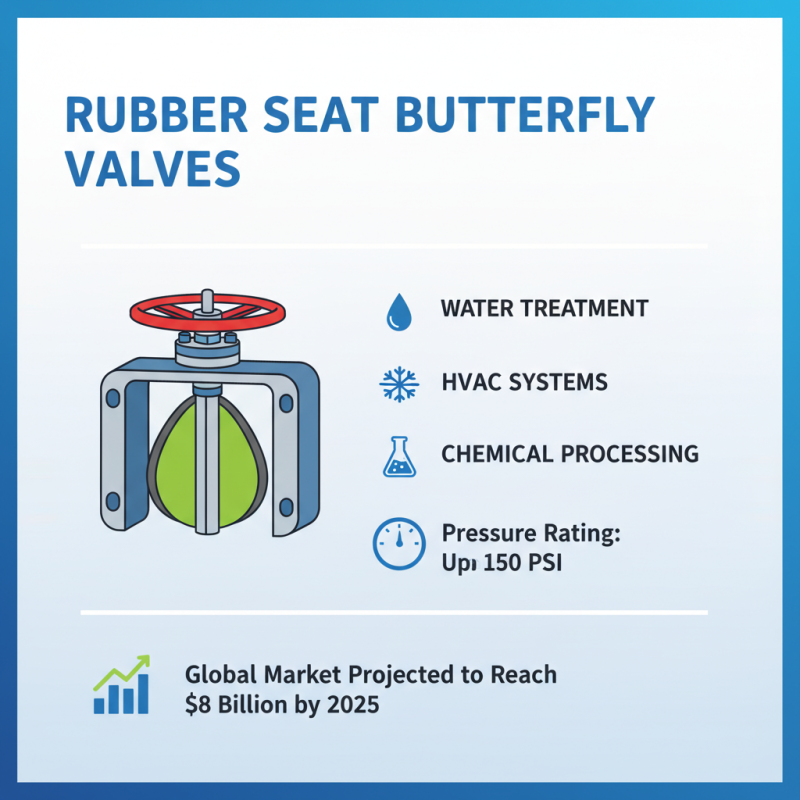

Rubber seat butterfly valves are versatile components used in various industries. They excel in applications involving water treatment, HVAC systems, and chemical processing. These valves offer excellent sealing capabilities. They can handle pressures up to 150 psi. According to industry reports, the global butterfly valve market is projected to reach $8 billion by 2025.

In water treatment facilities, these valves manage the flow of liquids effectively. Their rubber seating allows for smooth operation and prevents leakage. This is crucial in minimizing downtime. In chemical plants, they resist corrosive substances, enhancing their longevity. Nonetheless, it's essential to regularly check the valve's integrity to avoid system failures.

Tips for selecting the right valve include assessing the media type and operating pressure. Overlooking these factors can lead to increased costs and operational issues. Always consider the specific needs of your application. The right choice can improve efficiency and save energy. The wrong one may lead to leaks and repairs. Regular inspection is advisable to maintain optimal function.

When comparing rubber seat butterfly valves with other types of valves, several features stand out. The rubber seat provides excellent sealing capabilities. This helps to minimize leakage, making them ideal for many applications. Their lightweight design allows for easy installation and maintenance. In contrast, metal valves can be heavy and cumbersome. Rubber seats also resist corrosion better than some other materials. This characteristic enhances longevity.

Additionally, rubber seat butterfly valves operate at lower torque levels. This means less effort is required to open and close them. Other valves, such as gate or globe valves, often require more force. However, one must consider the limits of rubber seats. They may not hold up under extreme temperatures or pressures. In those scenarios, other valve types may be more reliable. Reflecting on these points can lead to better decision-making for specific applications.

Another aspect to consider is cost-effectiveness. Rubber seat butterfly valves are typically more affordable upfront. However, maintenance costs can vary depending on the environment. Industries dealing with harsh chemicals may face more frequent replacements. Balancing initial costs with long-term reliability is essential. Ultimately, choosing the right valve involves understanding the unique needs of your system.

| Feature | Benefits | Applications | Comparison with Other Valve Types |

|---|---|---|---|

| Corrosion Resistance | Longer service life in corrosive environments | Chemical processing, wastewater treatment | Better than metal valves for harsh environments |

| Low Torque Operation | Reduced effort for opening/closing | Water supply, irrigation | More efficient than gate valves requiring higher torque |

| Bubble-tight Sealing | Prevents leakage in critical applications | Pharmaceuticals, food processing | Superior sealing compared to plug valves |

| Lightweight Design | Easier handling and installation | HVAC systems, fuel handling | More portable than metal-bodied valves |

| Versatile Size Range | Fits various pipeline sizes | Oil & gas, municipal water systems | Flexibility unlike fixed size globe valves |

Proper maintenance of rubber seat butterfly valves is crucial for their longevity and performance. Regular inspection is vital. Check for signs of wear on the rubber seats. Any cracks or tears should not be ignored. This minor issue can lead to significant leaks over time.

Cleaning is another key aspect. Use a mild soap solution to clean the valve. Avoid harsh chemicals that could damage the rubber. Also, lubricate the operating mechanism regularly. This step ensures smooth operation and prevents rust. Observation during routine checks can reveal potential problems early.

Finally, keep an eye on the valve's environment. Excessive pressure or extreme temperatures can affect performance. Sometimes, adjustments to handle these conditions may be necessary. Be proactive about replacement when wear becomes evident. Ignoring these details can lead to costly repairs later. A little effort in maintenance can save a lot in the long run.