Leave Your Message

Choosing the right En593 Butterfly Valve is crucial for many industrial applications. With the market growing by over 5% annually, selecting the correct valve can significantly impact operational efficiency. According to industry expert Dr. James Carter, "A well-chosen butterfly valve not only enhances performance but also minimizes maintenance issues."

When evaluating options, consider the valve's material, size, and pressure rating. Industry reports highlight that almost 30% of valve failures stem from inappropriate sizing. The right choice increases durability and ensures long-term functionality.

Despite the available data, the decision process can feel overwhelming. Many professionals often overlook critical parameters. Observing market trends, it is evident that informed choices stem from careful analysis and reflection. Ensuring compatibility with existing systems is vital yet often underestimated. Thus, understanding details about the En593 Butterfly Valve becomes imperative for achieving optimal results.

When selecting an EN593 butterfly valve, consider the application. The valve's size and pressure rating are crucial. Smaller valves may be inadequate for high-pressure systems. Always check the specifications against your requirements. Ensure the valve can handle the temperature and media type. Different materials are used for different environments.

Another important factor is the actuator type. Manual, electric, and pneumatic options exist. Each has advantages and disadvantages. Manual valves require more effort. Electric valves offer precision but may need more maintenance. Pneumatic valves can be fast but rely on compressed air systems.

Tips for choosing wisely: think about the environment. Will the valve face corrosive substances? If so, select materials that resist damage. Also, consider the lifespan of the valve. A cheaper option may save money now but could lead to higher costs later. Look for a balance between quality and price, as duty cycles can impact both performance and durability. Always reflect on your choices to ensure they meet your long-term vision.

| Factor | Description | Considerations |

|---|---|---|

| Material | Choose the appropriate material based on fluid type and operating conditions. | Consider corrosion resistance, temperature, and pressure ratings. |

| Size | Select the right diameter to fit your piping system. | Ensure compatibility with existing pipes and fittings. |

| Actuation Type | Decide between manual, electric, or pneumatic actuators. | Consider automation needs and installation space. |

| End Connections | Check the type of connections compatible with your system (flanged, threaded). | Ensure proper fit and sealing ability. |

| Standards Compliance | Verify the valve meets industry standards (e.g., EN593). | Assess regulatory requirements for your application. |

Choosing the right EN593 butterfly valve is crucial for efficiency. Before purchasing, it’s essential to understand the different types available. The design of each valve affects its performance. Some are suitable for flow regulation, while others excel at quick shut-off. Knowing which one you need is critical.

Different materials also play a role. Stainless steel and ductile iron are popular choices. Each material has unique strengths. Stainless steel resists corrosion, ideal for harsh environments. Ductile iron, on the other hand, often provides better strength under pressure. Consider the specific application when selecting the material.

Don't forget about size and pressure ratings. A valve that is too small can restrict flow. Conversely, an oversized valve may lead to inefficient operation. Assess your system's requirements carefully. In some cases, adjustments may be needed post-installation. Always think critically about your options before making a final decision.

When choosing an EN593 butterfly valve, material selection is crucial. The right material affects both durability and functionality. Common choices include stainless steel, cast iron, and plastic. Each material has unique properties that cater to different applications. For instance, stainless steel offers excellent corrosion resistance. It's ideal for harsher environments, but can be more expensive.

Cast iron valves provide strength and stability. They work well in water systems but are prone to rust. If the wrong choice is made, leaks can occur. Plastic valves are lightweight and resistant to chemicals. However, they might not withstand high pressures. These details are essential when assessing performance and longevity.

Consider the operating conditions before making a decision. Temperature, pressure, and the type of fluid all play a role. Often, users overlook how material choices impact maintenance needs. A material that performs well initially may become problematic over time. It’s essential to reflect on long-term implications rather than just immediate costs.

When selecting an EN593 butterfly valve, understanding size and pressure rating is crucial. A valve too small will restrict flow, causing inefficiencies. Conversely, an oversized valve may lead to pressure drops and unstable operation. Evaluating the actual requirements can prevent these issues. Start by measuring the pipeline diameter where the valve will be installed. This ensures a perfect fit.

Pressure ratings vary significantly among valves. Different applications demand different ratings based on the fluid type and operating conditions. Assess the maximum pressure your system will encounter. It’s essential to choose a valve that meets or exceeds this rating. Remember that safety is paramount. A valve rated too low can fail under pressure, leading to potential hazards.

Always consider the medium flowing through the valve. Different materials hold up against wear and corrosion differently. Make sure to match the valve’s material with the flow's properties. Think about the long-term implications of your choice. A mismatch could lead to costly replacements or repairs in the future. It's not just about immediate needs; consider future scenarios too.

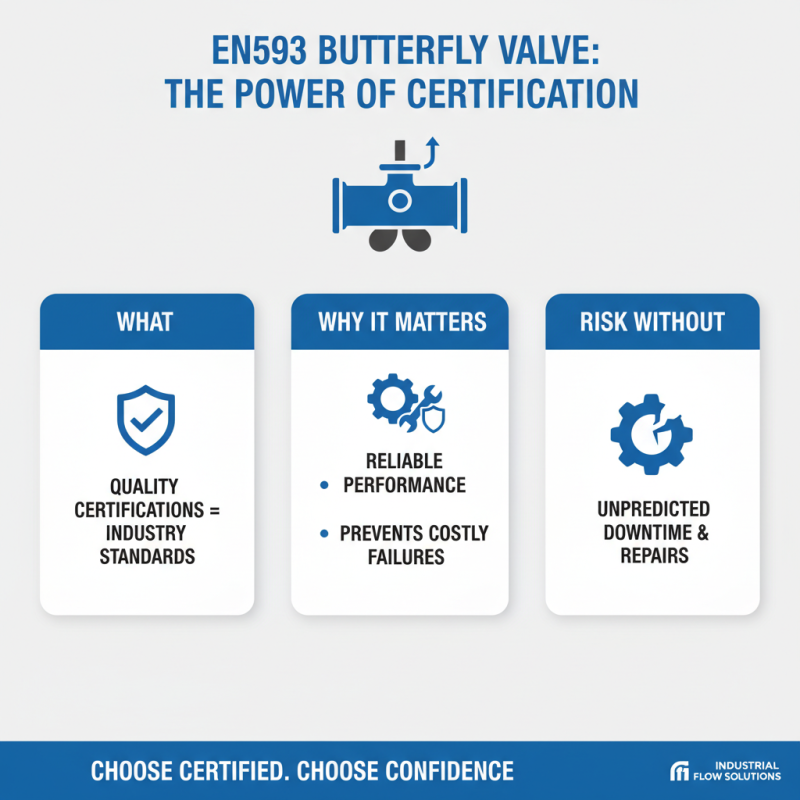

When selecting an EN593 butterfly valve, quality certifications play a crucial role. These certifications ensure that the valves meet industry standards. A valve with proper certification is likely to perform reliably in various applications. Without this, you might face unexpected failures that can lead to costly repairs and downtime.

Check for relevant standards from organizations like ISO or API. If a valve lacks these certifications, be cautious. Such valves might not endure extreme conditions. Quality certifications are a safety net, helping you avoid potential operational risks.

Tip 1: Evaluate the materials used in the valve. High-quality materials resist corrosion and wear. Tip 2: Consider the size and pressure ratings. Ensure they match your system requirements. It’s easy to overlook these details, but they are vital. Skipping them can lead to misalignment later.