Leave Your Message

In many industries, flow control is crucial. The Butterfly Valve is a key component for this purpose. It allows for efficient regulation of fluid flow, making processes smoother. However, choosing the right Butterfly Valve can be challenging.

This article highlights the top 10 Butterfly Valve options available today. Each valve has its unique features that enhance performance. Some valves are made from durable materials, while others offer advanced technology for better control. It's important to consider the specifics of your application.

Adopting the wrong Butterfly Valve might lead to inefficiencies. That choice could cause leaks or pressure issues. Thus, careful selection matters. Our guide aims to provide clarity and direction. By understanding various options, you can make an informed decision that improves your flow control systems.

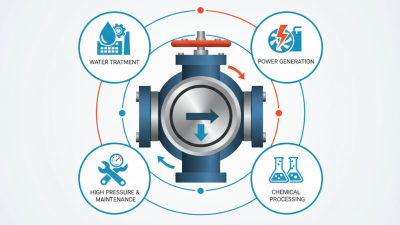

Butterfly valves play a crucial role in flow control across various industries. They consist of a rotating disc that regulates media flow. According to a report by MarketsandMarkets, the global butterfly valve market is expected to reach $8.5 billion by 2026. This growth highlights their importance in applications ranging from water supply to chemical processing.

The design of butterfly valves allows for quick operation and efficient flow. Their simple construction can reduce maintenance needs. However, not all butterfly valves perform equally. Material selection and sealing technology significantly impact their effectiveness. A study indicates that improper valve selection can lead to flow inefficiencies, sometimes exceeding 30%. This highlights a critical need for careful consideration of specific requirements.

Additionally, the environmental impact cannot be ignored. Some materials used in valve construction may not be fully recyclable. This raises questions about sustainability in the industry. Further investigation is needed to balance performance and ecological responsibility. Ultimately, while butterfly valves offer efficient flow control, there is room for improvement in design and material choices.

| Valve Type | Size (inches) | Material | Pressure Rating (psi) | Temperature Rating (°F) |

|---|---|---|---|---|

| Lug Style | 2" | Cast Iron | 150 | 250 |

| Wafer Style | 4" | Stainless Steel | 200 | 300 |

| Exotic Material | 6" | Hastelloy | 600 | 500 |

| Double Eccentric | 8" | Carbon Steel | 300 | 400 |

| Triple Eccentric | 10" | Alloy 20 | 600 | 800 |

| Plastic | 1/2" | PVC | 150 | 140 |

| Flanged | 12" | Ductile Iron | 250 | 300 |

| Sanitary | 6" | 316 Stainless Steel | 150 | 250 |

| Electric Actuator | 4" | Aluminum | 150 | 180 |

| Pneumatic Actuator | 8" | Stainless Steel | 300 | 350 |

When selecting a butterfly valve, key features must be considered for optimal flow control. First, look at the materials. The valve body should withstand the operating environment. Common materials include brass, stainless steel, and plastic. Each has its own advantages. For example, plastic is lightweight but may not handle high pressure as well.

Another vital aspect is the valve size. Correct sizing ensures efficient flow and minimizes pressure losses. A small valve might restrict flow, while a large one can be unnecessarily costly. Understanding the flow requirements and pipe dimensions is essential.

Tips: Always verify the pressure rating. It’s crucial for performance. Also, consider ease of installation. Some designs may require special fittings or tools. Assess these factors before making a purchase. Lastly, check for maintenance needs. Some valves are easier to maintain than others.

The design type matters as well. Choose between wafer-style, lug-type, or flanged valves based on your application. Each has pros and cons. Lug-types can be easier to install in tight spaces, yet they typically cost more. Weigh these options carefully, ensuring you select the right fit for your needs.

When it comes to flow control in piping systems, choosing the right butterfly valve is crucial. Several models stand out for their efficiency and reliability. Recent industry reports show that these valves can significantly reduce energy consumption by up to 30%. This makes them an ideal choice for various applications.

A recommended model is designed with a lightweight body. It also features a durable disc that resists corrosion. Users report ease of installation and maintenance. However, some models may struggle under extreme pressure. It's important to assess your specific requirements before selecting a valve.

Tips for optimal performance include regular maintenance checks. Inspect seals and actuators. This can prevent common issues like leaks. Additionally, consider the valve’s material compatibility with the media being controlled. This ensures longevity and effectiveness.

Investing in a high-quality butterfly valve can lead to long-term savings. However, not every product guarantees perfect performance. Collect user feedback and case studies to inform your decision. Understanding the potential pitfalls can help in making the right choice.

When selecting butterfly valves, the material used plays a crucial role in performance. Common materials include cast iron, stainless steel, and PVC. A recent industry report highlighted that stainless steel valves exhibit better corrosion resistance, particularly in harsh environments. They can withstand higher temperatures and pressures, making them suitable for the oil and gas sector.

Cast iron, on the other hand, is cost-effective but may fail under extreme conditions. It is more prone to rust, which can compromise flow efficiency over time. The American Society of Mechanical Engineers reports that nearly 30% of valves in industrial applications face premature failures due to material-related issues. This information underscores the need for careful material selection.

Additionally, there is a growing trend towards composite materials in the industry. Composite butterfly valves offer enhanced durability and lower weight. They can also be molded into complex shapes, allowing for innovative designs. However, the performance of these materials under extreme wear is still being studied. There is much room for improvement in material technology. The ongoing research might redefine standards in flow control reliability.

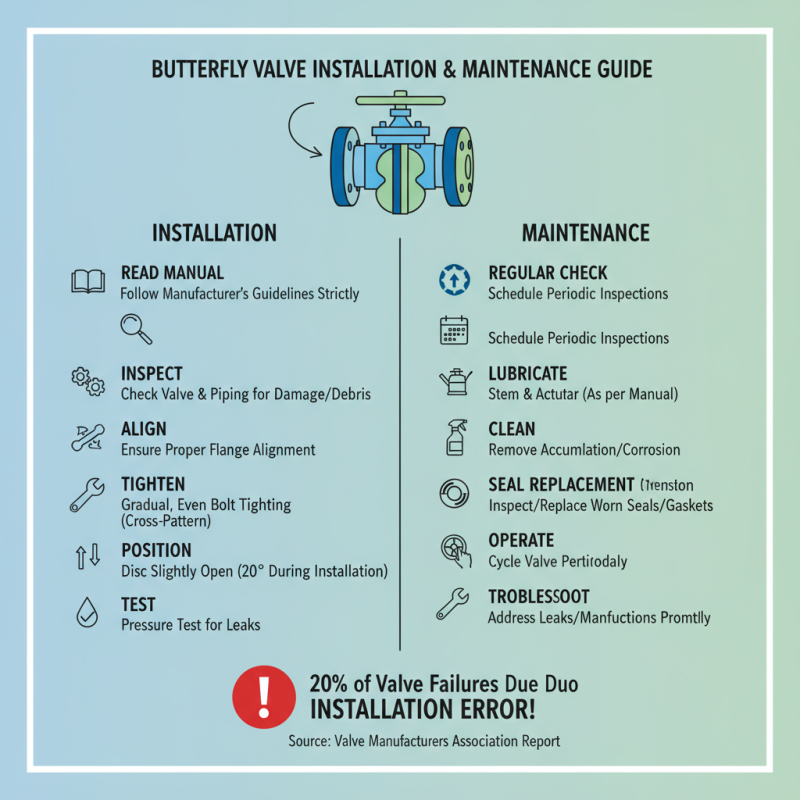

Installing and maintaining butterfly valves requires attention to detail. Improper installation can lead to leaks and reduced efficiency. According to a report from the Valve Manufacturers Association, nearly 20% of valve failures arise from installation errors. It's crucial to follow the manufacturer’s guidelines strictly.

Before installation, ensure the pipeline is clean. Any debris can affect seating. Inspect flanges and alignment to avoid stress on the valve. Utilize proper gaskets to prevent leaks. A gap can lead to significant flow loss. Studies show that a small misalignment can reduce a valve's lifespan by 30%, underscoring the importance of precision.

Regular maintenance is necessary for optimal performance. Inspect the valve for wear and tear. Lubricate moving parts to prevent sticking. A study published by the Flow Control Institute found that 15% of valves fail due to lack of maintenance. Schedule routine checks to ensure that the valve operates efficiently. Address any unusual noises or leaks immediately to avoid bigger issues. Each of these steps contributes to maintaining effective flow control in various applications.