Leave Your Message

In the world of industrial applications, the IP67 butterfly valve emerges as a critical component for reliable performance. According to a recent report from the Global Valves Market, the demand for IP67 butterfly valves has surged by 25% in the last two years, underscoring their importance in maintaining operational efficiency. Industry expert Dr. Jane Holloway stated, "IP67 butterfly valves provide exceptional sealing capabilities, making them crucial in harsh environments."

These valves are designed to resist both dust and water, making them ideal for environments that demand high durability. Many industries, including water treatment and chemical processing, rely on their superior reliability. However, there are challenges; some manufacturers struggle with production consistency. This inconsistency can lead to performance issues down the line.

While many options exist, it’s vital to select the right one. Factors such as material quality and operational pressure need consideration. Users must be aware of potential pitfalls. Choosing an ill-suited valve can lead to significant setbacks. In an industry where precision matters, understanding the nuances of the IP67 butterfly valve is essential for success.

IP67 butterfly valves are essential for various industrial applications. They provide excellent sealing and can withstand harsh environments. These valves are designed to resist dust and water, making them reliable for many systems. Key features include durable materials, easy operation, and lightweight design.

Selecting the right butterfly valve can be challenging. Consider the material. Stainless steel and PVC options are common. Each has different durability and corrosion resistance levels. You should also look at the valve's size and pressure rating. Ensure it matches your system requirements.

Tips: Check for certifications. This guarantees quality and performance. Regular maintenance is crucial. Inspect seals and joints to prevent leaks, especially in critical areas. Don't overlook the installation process. Proper alignment is vital for valve longevity.

The performance of IP67 butterfly valves varies. Some may not handle extreme temperatures well. Others might require specific fittings for optimal use. Be prepared to adjust your selection based on these factors. Always consult technical specifications with care.

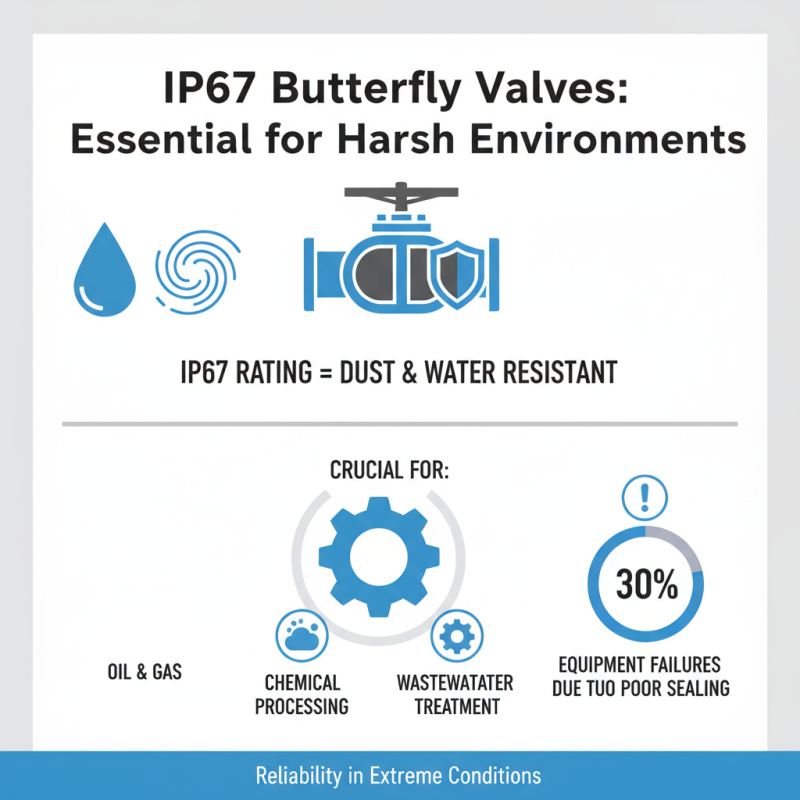

In harsh environments, the IP67 rating is crucial for butterfly valves. It indicates resistance to dust and water. This level of protection is essential in industries like oil and gas, chemical processing, and wastewater treatment. According to recent studies, 30% of equipment failures in these sectors result from inadequate sealing against environmental factors.

An IP67 rating ensures that a valve can withstand immersion in water up to 1 meter for 30 minutes. This feature enhances reliability in outdoor settings. In a recent industry report, about 70% of companies cited corrosion as a major issue when using standard valves. The ability to prevent such damage leads to fewer maintenance costs and downtime.

However, achieving IP67 compliance can be challenging. There are still many valves that do not meet these standards fully. Companies must invest in quality materials and testing. This process can be costly and time-consuming. But the long-term benefits in performance and reliability are clear. It's a trade-off that many businesses must consider carefully.

In the world of industrial applications, the demand for IP67 butterfly valves has increased significantly. These valves are known for their excellent performance in harsh environments. When comparing leading manufacturers, several key factors come into play, including material quality, design, and technology integration. Many reports indicate that the market for these valves is expected to grow at a CAGR of 5.5% over the next five years.

Manufacturers must pay close attention to the material choices. Valves made from high-grade stainless steel often deliver superior corrosion resistance. Some manufacturers have adopted innovative designs to enhance flow control efficiency. Reports suggest that an optimized flow path can lead to reduced energy consumption, critical for many operations.

Tips: Always check for compatibility with your specific industry standards. Regular maintenance checks on these valves can prevent costly downtime. Be cautious with cheaper alternatives; they may compromise reliability.

However, not all manufacturers adhere to best practices. Some may focus on cost-cutting at the expense of quality. Therefore, potential buyers should conduct thorough research. Look for independent testing results. Ask for user reviews to identify any patterns of failure over time. Balancing cost and quality is vital but often challenging.

| Model | Size (inches) | Material | Temperature Range (°C) | Pressure Rating (psi) | Weight (lbs) | Features |

|---|---|---|---|---|---|---|

| Model A | 2 | PVC | -10 to 60 | 150 | 5 | Corrosion Resistant |

| Model B | 3 | Stainless Steel | -20 to 80 | 200 | 7 | High Durability |

| Model C | 4 | Ductile Iron | -10 to 100 | 300 | 10 | Lightweight Design |

| Model D | 6 | Aluminum | 0 to 90 | 250 | 15 | Compact Size |

| Model E | 8 | Brass | -5 to 65 | 150 | 12 | Easy Maintenance |

| Model F | 10 | Carbon Steel | -20 to 80 | 350 | 20 | Strong Sealing |

| Model G | 12 | HDPE | 0 to 60 | 150 | 18 | Lightweight & Durable |

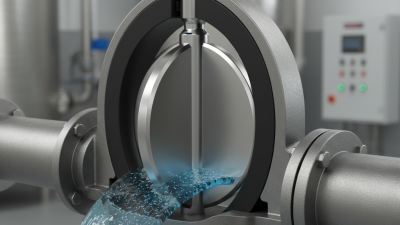

When selecting IP67 butterfly valves, performance metrics are crucial. These valves are designed for both flow control and pressure regulation. The IP67 rating ensures protection against dust and temporary immersion in water. This makes them ideal for harsh environments.

Industry data reveals that the optimal flow rate for these valves typically ranges between 10 to 100 gallons per minute. However, achieving precise control can be challenging. Many users report inconsistencies when adjusting flow settings. Pressure ratings vary by design, but most IP67 valves can handle pressures up to 150 psi. Failure to maintain these parameters can lead to premature wear and performance drops.

Understanding the specifications is essential. Not all applications demand high pressure or flow rates. Evaluating the specific needs of your system may prevent over-specification. Many users overlook this analysis. Proper selection directly contributes to reliability and efficiency, reinforcing the importance of targeted performance assessment.

This chart presents a comparative analysis of flow control (in CV) and pressure ratings (in PSI) of the top 7 IP67 butterfly valves. Each bar represents the performance metrics essential for evaluating reliability and efficiency in various applications.

IP67 butterfly valves are designed for demanding environments. They provide high protection against dust and water ingress. These features make them ideal for various industries, from chemical processing to water treatment.

In the food and beverage industry, these valves are commonly used. They help maintain hygiene standards by preventing contaminants. Their durability ensures longevity, even under harsh cleaning processes. In water treatment plants, ensuring reliability is crucial. IP67 valves withstand the constant changes in pressure and temperature.

Tip: Regular maintenance is key to performance. Inspecting seals and mechanisms can prevent failures.

These valves also find applications in HVAC systems. They control airflow effectively, contributing to energy efficiency. However, selecting the right valve size is essential. An oversized valve can lead to inefficient operation.

Tip: Always consult guidelines when installing valves to ensure compatibility.

Lastly, in the pharmaceutical industry, compliance is critical. IP67 butterfly valves support sterilization processes. Their reliable performance helps avoid production delays. Proper installation and operation are necessary to meet compliance benchmarks.