Leave Your Message

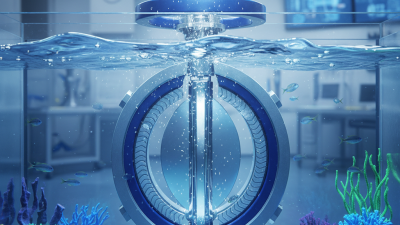

In the evolving landscape of fluid control systems, the Pn10 Butterfly Valve stands out for its unique combination of design efficiency and operational reliability. As industry expert Dr. Robert Johnson, a leading authority on valve technology, states, "The Pn10 Butterfly Valve not only ensures optimal flow management but also significantly reduces maintenance costs, making it a preferred choice in various applications." This statement encapsulates the growing recognition of the Pn10 Butterfly Valve's importance across sectors such as water treatment, HVAC, and industrial processes.

The features and specifications of the Pn10 Butterfly Valve, coupled with its inherent benefits, are reshaping industry standards. With a nominal pressure rating of 10 bar, this valve model is engineered for durability and performance, providing a secure solution for managing fluid flow in a variety of conditions. Its design allows for quick installation, and its lightweight structure facilitates ease of handling, enhancing operational efficiency.

Moreover, the Pn10 Butterfly Valve's versatility means it can be utilized in diverse environments, from municipal water systems to complex industrial pipelines. As we delve deeper into this analysis, we will explore the standout features, comprehensive specifications, and the distinct advantages that make the Pn10 Butterfly Valve an indispensable component in modern engineering solutions.

The 2025 PN10 butterfly valve is an essential component in a variety of industrial applications, primarily due to its characteristic ease of operation and reliability. These valves are designed to manage flow with minimal resistance, providing superior performance in pressure ratings up to PN10. Key features include a lightweight construction that ensures easier installation and maintenance, alongside a compact design that saves valuable space. Additionally, the valve's robust sealing mechanism enhances durability and minimizes leakage, which is pivotal in high-demand environments such as water treatment facilities and chemical processing plants.

In recent industry reports, the global butterfly valve market is projected to grow at a compound annual growth rate (CAGR) of 4.8% from 2023 to 2028, driven by rising investments in infrastructure development. This demand underscores the importance of assets like the PN10 butterfly valve, which are increasingly favored for their efficiency and versatility. Applications range from HVAC systems to pulp and paper processing, showcasing their broad utility across various sectors.

Tips: When selecting a butterfly valve, always consider the specific characteristics of your application, including temperature, pressure, and fluid type. Proper sizing is crucial—an oversized valve can lead to excessive wear and operational inefficiency. Additionally, regular maintenance and inspection are vital for ensuring long-term performance and reliability in high-stakes settings.

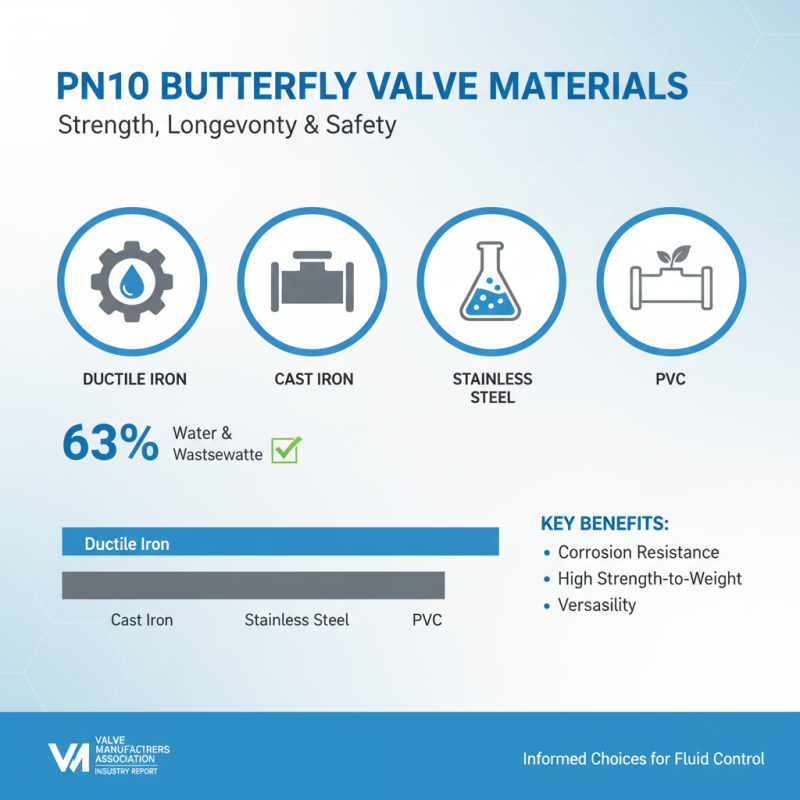

When considering the material specifications for PN10 butterfly valves, it is crucial to understand the influence of material selection on performance, longevity, and safety. The most commonly used materials for constructing these valves include ductile iron, cast iron, stainless steel, and PVC. According to a recent industry report by the Valve Manufacturers Association, 63% of butterfly valves are made from ductile iron due to its excellent strength-to-weight ratio and corrosion resistance. This makes ductile iron an ideal choice for applications involving water and wastewater treatment processes.

Additionally, the gasket materials selected for PN10 butterfly valves play a significant role in preventing leaks and ensuring a tight seal. Common gasket materials include EPDM, NBR, and PTFE, which can withstand a variety of temperature and pressure conditions. A survey from a leading industrial valve consulting firm revealed that valves with PTFE gaskets exhibit a 25% increase in service life compared to those with standard NBR gaskets. Understanding these material specifications enables engineers and designers to optimize valve performance and reliability for critical applications across various industries, including HVAC, chemical processing, and irrigation systems.

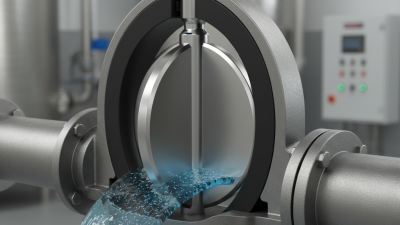

The performance metrics of a PN10 butterfly valve are critical for understanding its efficacy in various applications. Among these metrics, the flow coefficient (CV) is essential as it quantifies the valve’s flow capacity under defined conditions. A higher CV indicates that the valve can pass more fluid through it with less pressure drop, making it ideal for systems requiring high flow rates. This characteristic becomes particularly important in industries where maintaining flow efficiency can significantly impact overall operational costs and system performance.

In addition to the flow coefficient, pressure ratings are vital for ensuring the reliability and safety of the valve in different operational environments. PN10 indicates that the valve is rated for a maximum pressure of 10 bar, which defines its suitability for various applications, from water supply systems to industrial processes. Understanding the implications of these pressure ratings allows engineers to better select valves that meet the necessary durability and safety standards, ensuring that the systems maintain optimal performance without risking failure or leaks due to excessive pressure.

| Feature | Specifications | Benefits | Performance Metrics |

|---|---|---|---|

| Body Material | Ductile Iron | Durability and corrosion resistance | High flow capacity |

| Seal Type | EPDM | Excellent sealing properties | Low leakage rates |

| Size Range | 2" to 12" | Versatility in various applications | Customizable for different installations |

| Pressure Rating | PN10 | Reliable performance under pressure | Suitable for various media types |

| Flow Coefficient (Cv) | > 100 | Enhanced flow efficiency | Optimized for energy savings |

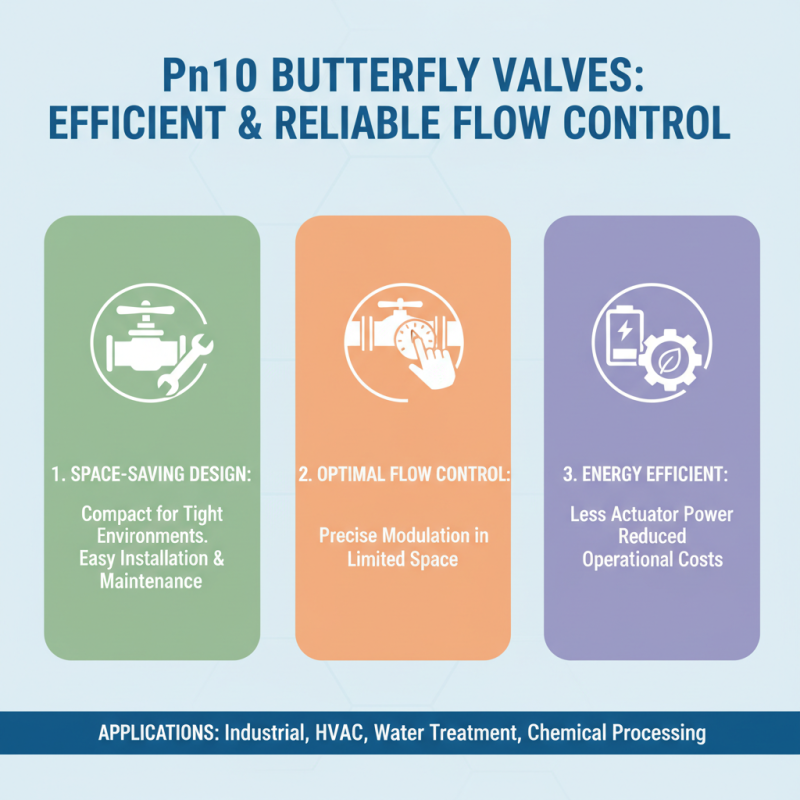

Pn10 butterfly valves have become increasingly popular across various industries due to their efficiency and reliability. One of the primary benefits of using these valves is their ability to provide excellent flow control in systems where space is limited. Their compact design allows for easy installation and maintenance, making them ideal for tight environments. Additionally, Pn10 butterfly valves require less actuator power compared to other valve types, which contributes to energy savings in operational processes.

In industries such as water treatment, food and beverage, and chemical processing, the versatility of Pn10 butterfly valves proves advantageous. They can handle a wide range of media, including liquids and gases, while maintaining a durable performance under various pressures. This adaptability ensures that companies can use them across multiple applications without needing extensive modifications. Furthermore, the quick opening and closing capabilities of butterfly valves enhance system responsiveness, reducing the risk of delays and improving overall operational efficiency. This combination of reliability and versatility underscores the growing preference for Pn10 butterfly valves in industrial settings.

When comparing Pn10 butterfly valves to other valve types, it is essential to consider their unique features and advantages. Pn10 butterfly valves are designed for low-pressure applications, making them particularly suitable for a variety of industrial settings. Their simple structure, comprising a rotating disk that regulates flow, allows for quick and efficient operations. This design not only minimizes pressure drops but also contributes to energy savings. In contrast, other valve types such as globe valves or ball valves may offer greater sealing capabilities but often at the expense of increased flow resistance and complexity in maintenance.

Additionally, the lightweight construction of Pn10 butterfly valves facilitates easier installation and positioning, especially in tight spaces. They typically require less material for manufacturing compared to other valve designs, which can lower costs in large projects. While globe and ball valves excel in high-pressure applications with superior throttling capabilities, they may not be as efficient in scenarios where space and weight restrictions are a concern. Ultimately, the choice between Pn10 butterfly valves and other types boils down to the specific requirements of the application, including pressure ratings, flow control needs, and installation constraints.

This chart compares the specifications of Pn10 Butterfly Valves with other valve types across four dimensions: flow rate, pressure drop, weight, and cost. The Pn10 Butterfly Valve demonstrates superior flow rate and lower weight compared to other types, while being cost-effective.