Leave Your Message

In the world of marine engineering, Sea Water Butterfly Valves play a crucial role. These valves manage the flow of seawater in various applications, from ship systems to coastal infrastructure. Dr. Emily Thompson, a renowned expert in marine valve technology, once stated, "The reliability of Sea Water Butterfly Valves is essential for sustainable coastal operations."

Choosing the right Sea Water Butterfly Valve can significantly affect the efficiency and safety of marine projects. However, not all valves are created equal. Factors like corrosion resistance and operational durability are vital for success in marine environments. Experts emphasize that the right choice can prevent costly repairs and downtime.

Despite advancements, selecting an appropriate valve can be challenging. Different manufacturers offer various features, but the ideal valve should meet specific project requirements. Evaluating each option is necessary, yet it may lead to potential oversights. Ultimately, understanding the top 10 Sea Water Butterfly Valves is key for engineers and decision-makers in this vital sector.

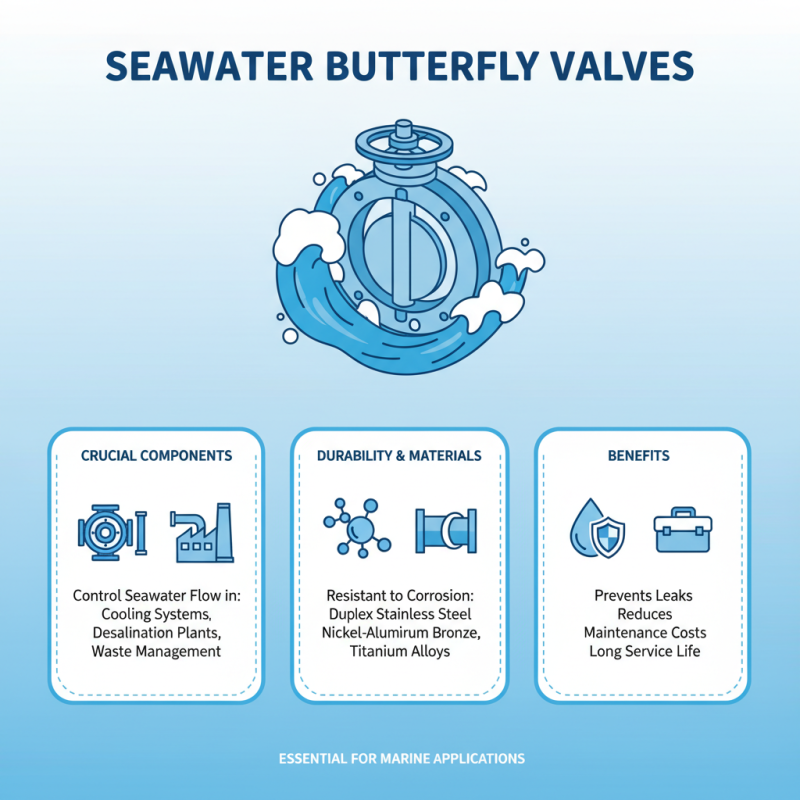

Sea water butterfly valves are crucial components in various marine applications. They control the flow of seawater in systems like cooling, desalination, and waste management. The corrosive nature of seawater demands strong, durable materials. These valves help prevent leaks and reduce maintenance costs.

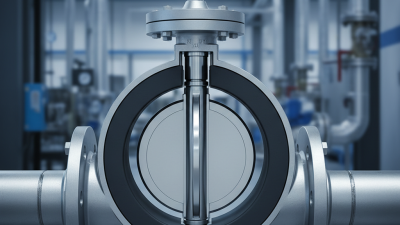

The design of these valves must be robust. Testing their performance can reveal areas needing improvement, such as sealing or material resistance. Butterfly valves commonly have a simple structure, making them easy to operate. However, not all designs withstand extreme marine conditions. Choosing the right valve is essential. Misjudgments can lead to costly failures.

Consider the installation process. Properly aligning and securing the valve can avoid future issues. Regular inspections are necessary too. They allow operators to spot corrosion early. Issues may arise even after installation, showing the importance of routine check-ups. Investing time in these practices ensures longevity and reliability.

When choosing sea water butterfly valves, key features play a critical role. The material of the valve is essential. Corrosion resistance is a must. Options like PVC and bronze are common. But, don't overlook the quality of the rubber seals. They ensure a tight shut-off. The design should facilitate easy maintenance. Complex designs may lead to issues down the line.

Another feature to consider is the size. Ensure it fits your piping system accurately. Oversized or undersized valves can lead to inefficient operations. You should assess the pressure rating too. It must match the requirements of your system.

Tips: Always consult with a professional about specifications. Look into user reviews for real-world performance. Testing in your specific application can reveal unexpected drawbacks. Anticipate the possibility of needing replacements or repairs. It’s wise to have a backup plan!

| Model | Size (inches) | Material | Pressure Rating (PSI) | Temperature Rating (°F) | Key Features |

|---|---|---|---|---|---|

| Model A | 2 | PVC | 150 | 120 | Corrosion-resistant, Lightweight |

| Model B | 3 | Ductile Iron | 200 | 180 | High strength, Durable |

| Model C | 4 | Stainless Steel | 250 | 200 | High temperature resistance, Anti-corrosive |

| Model D | 5 | Bronze | 150 | 150 | Good wear resistance, Smooth flow |

| Model E | 6 | PP | 100 | 140 | Lightweight, UV resistant |

| Model F | 8 | Nickel Alloy | 300 | 220 | Exceptional resistance to seawater, Heavy duty |

| Model G | 10 | Aluminum | 180 | 160 | Lightweight, Easy installation |

| Model H | 12 | Fiberglass | 150 | 180 | Corrosion-resistant, Lightweight |

| Model I | 14 | Carbon Steel | 250 | 200 | High pressure tolerance, Robust design |

| Model J | 16 | Thermoplastic | 100 | 140 | Excellent chemical resistance, Lightweight |

When it comes to sea water butterfly valves, certain brands and models stand out in the market. These valves handle high-pressure, saline water effectively. They are crucial in coastal facilities, desalination plants, and marine applications. Selecting the right model can ensure longevity and robust performance.

One notable feature is corrosion resistance. Many options use specialized materials to withstand harsh environments. Some designs offer enhanced sealing capabilities. Users should consider specific operational needs to find the best fit. It's essential to examine the flow control efficiency of each model.

However, not all choices are perfect. Some valves may require frequent maintenance. Users occasionally report issues with installation. It's vital to balance cost with performance. Consideration of user feedback can guide potential buyers. Ultimately, reviewing specifications enhances informed decision-making.

Installing sea water butterfly valves requires careful attention. Ensure all connections are tight. Leaks can lead to serious issues. Use appropriate sealants to prevent corrosion.

Regular maintenance is essential for optimal function. Inspect the valves quarterly. Check for signs of wear or buildup of salt. Keep moving parts well-lubricated to avoid jamming.

Tips: Clean the valve with fresh water after use. This simple step extends the life of the valve. Always refer to best practices for installation. Skipping this can result in costly repairs down the line. Remember, small mistakes can have big consequences.

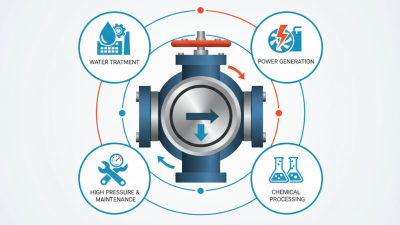

Sea water butterfly valves are crucial components in various industries. They efficiently control the flow of seawater in diverse applications. These valves are widely used in marine facilities, power plants, and water desalination processes. Their design allows for smooth operation even in harsh marine environments.

In the oil and gas sector, these valves are often utilized for offshore drilling. They help manage seawater flow in cooling systems. Aquaculture also benefits from their use. Farmers employ these valves to regulate water exchange in fish farms. However, maintenance can be challenging due to corrosion issues from saltwater exposure.

Moreover, sea water butterfly valves play a significant role in irrigation systems. They enhance water management in coastal agricultural areas. Planning regular inspections is vital. Even a minor issue can escalate quickly without vigilant monitoring. Perhaps the industry needs better strategies for addressing these challenges. After all, the efficiency of operations heavily relies on reliable valve performance.