Leave Your Message

In industrial applications, reliable valve selection is crucial. One of the standout options is the Zero Leakage Butterfly Valve. This valve offers exceptional performance and efficiency. Its design minimizes the risk of leaks, which can lead to costly downtime.

Choosing the right valve can be challenging. Many options flood the market. However, the Zero Leakage Butterfly Valve stands out for its durability and precision. It prevents fluid escape effectively. This feature is essential for many industries, from oil and gas to water treatment.

Adopting this valve can enhance system reliability. The promise of zero leakage improves safety standards. It is not just about performance; it's about building trust. Some may question if it's worth the investment. Reflecting on long-term benefits can guide this decision.

Zero leakage butterfly valves are essential in many industrial applications. These valves prevent leaks effectively, maintaining system integrity. Industries rely on them for superior performance. The design minimizes the chances of fluid escaping, which is critical in processes involving hazardous materials.

These valves also reduce maintenance costs. With minimal leakage, there’s less risk of environmental damage. They help maintain pressure and flow efficiency, contributing to overall system reliability. The ease of installation and operation makes them favorable. However, not all systems are compatible, and careful consideration is needed.

In some cases, achieving zero leakage can be a challenge. It requires precise engineering and quality materials. Companies must evaluate the valve's performance over time. Some users may find the initial investment high. Nonetheless, the long-term benefits often outweigh the drawbacks. Efficient operations demand reliable components, which makes zero leakage butterfly valves a wise choice for industrial needs.

When considering valves for fluid control, zero leakage butterfly valves stand out. Their design ensures minimal to no fluid loss. This feature is crucial in industries where efficiency and safety are paramount. Leaks can lead to costly downtime. Choosing a zero leakage solution means reduced waste and lower operational costs.

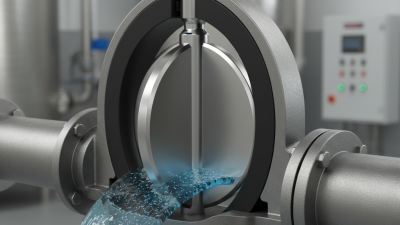

The zero leakage design relies on high-quality materials. These materials create a tight seal, preventing any escape of fluids. The precision engineering involved is impressive. A well-made butterfly valve can withstand high pressures and varying temperatures. This durability extends its service life. However, not all products live up to these standards. It's vital to assess each option carefully.

Regular maintenance plays a role in performance. Even the best valves need checks. Wear and tear over time can compromise the seal. Sometimes, a simple adjustment can fix an issue. Other times, replacement may be necessary. Knowing when to act can save time and money. Ignoring small leaks may lead to bigger problems down the line.

| Feature | Description | Applications | Material Types |

|---|---|---|---|

| Leakage Prevention | Zero leakage design ensures no fluid escapes, enhancing system efficiency. | Oil and Gas, Water Treatment | Stainless Steel, PVC |

| Low Torque Operation | Requires less torque to operate, reducing wear and extending valve life. | HVAC Systems, Chemical Processing | Carbon Steel, Cast Iron |

| Durability | Designed to withstand harsh conditions, improving service life and reliability. | Pulp and Paper, Power Generation | Alloy Steel, Bronze |

| Maintenance Free | Minimal maintenance required, saving on operational costs over time. | Food and Beverage, Mining | Thermoplastics, Composite Materials |

| Versatility | Can handle a wide range of fluids, including viscous and hazardous materials. | Chemical Handling, Waste Water Treatment | EPDM, Nitrile Rubber |

Zero leakage butterfly valves are essential in many industrial applications. These valves prevent fluid loss, ensuring efficient operation. When considering their use, it's crucial to understand the industry standards and certifications that ensure quality and performance. Compliance with these standards guarantees that the valves meet safety and reliability benchmarks.

Various organizations establish guidelines for zero leakage valves. For instance, certifications like ISO 9001 focus on quality management. Other standards address materials, testing procedures, and environmental concerns. Valves must be rigorously tested to confirm they can withstand high pressures and corrosive substances. However, not all manufacturers may adhere strictly to these guidelines, leading to potential performance issues.

Regular audits and inspections can help identify non-compliant products. It's important to choose valves that not only promise zero leakage but also have verifiable certifications. Users should be cautious of overly optimistic claims. Real-world performance may vary dramatically. Awareness of these factors ensures that organizations invest in reliable equipment that meets their industrial needs effectively.

When selecting a valve for industrial applications, leakage rates are crucial. Zero leakage butterfly valves stand out due to their performance in preventing leaks. Unlike traditional valves, these models achieve a complete seal, making them ideal for critical systems. They operate with minimal friction, reducing wear over time.

Comparing different valve types reveals significant differences in leakage rates. Many valves leak, even under low pressure. In contrast, zero leakage valves ensure that no fluids escape. This is vital in processes that require precision. Industries such as pharmaceuticals and food production need absolute reliability.

However, this design is not without its challenges. Installation can be tricky, requiring expertise. Maintenance may also become an issue over time. Users should reflect on their specific needs before selecting. Understanding the operational environment plays a key role in making a choice. Balancing initial costs with long-term benefits is essential.

Zero leakage butterfly valves are increasingly popular for industrial applications. Their design ensures minimal fluid loss during operation. This contributes to significant cost savings over time. Many industries face challenges with regular valve leaks, leading to waste and increased operational costs. Choosing the right valve can mitigate these issues effectively.

The longevity of zero leakage butterfly valves is noteworthy. These valves are built to withstand harsh conditions. They reduce maintenance needs, allowing for more efficient operations. Many companies report lower downtime due to valve failures. Fewer replacements mean lower overall costs. However, there can be concerns about their initial investment. Some may hesitate, questioning whether the upfront cost is justified.

It is essential to evaluate long-term benefits versus short-term expenses. Calculating total cost of ownership can provide insights. A proactive approach is beneficial. Companies must consider the potential losses caused by leaks. Ultimately, investing in quality valves could lead to greater profitability.