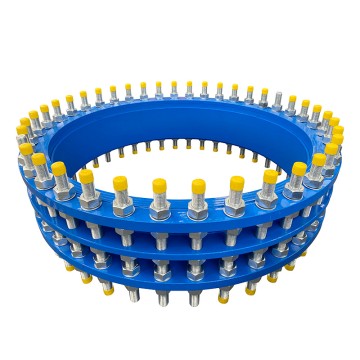

Premium Butterfly Check Valve from Reliable Exporters with Outstanding Service

As a premier manufacturer of Butterfly Check Valves, we specialize in delivering high-quality OEM products tailored to meet specific needs. Our valves are precisely engineered to ensure optimal performance and reliability across a range of industrial applications. Built from durable materials, they are designed to withstand challenging environments, making them ideal for fluid control systems. At NEWSTAR VALVE (ZHENGZHOU) CO., LTD., we prioritize efficiency and safety in your operations; our valves undergo rigorous testing to meet industry standards. With the support of our expert team, you'll find customized solutions that align with your project requirements.Must-Know Tips For Butterfly Check Valve Custom Solutions, Trusted by Pros

When it comes to sourcing Butterfly Check Valves, understanding the nuances of customized solutions is essential for making informed decisions. Customized Butterfly Check Valves offer flexibility that standard valves cannot match, allowing businesses to tailor specifications to their unique operational requirements. Key considerations when seeking custom solutions include material selection, pressure ratings, and size specifications, which are crucial to ensure compatibility with your system. Furthermore, when working with a manufacturer, it's important to inquire about their design capabilities and experience in producing low and middle pressure valves. A reliable manufacturing partner will provide insights into their development process, ensuring that your custom valves not only meet quality standards but are also efficient and durable. Engaging with experienced manufacturers who prioritize innovation and quality assurance can significantly enhance the reliability of your applications. Lastly, understanding the logistics involved in the procurement of these custom solutions is vital. Ensure that your supplier can efficiently manage delivery timelines and offer support throughout the installation and maintenance phases. Building a strong communication line with your manufacturer will facilitate adjustments and improvements based on feedback, ensuring that the custom Butterfly Check Valves perform optimally in your operational environment. Trusting your procurement process with knowledgeable professionals can lead to long-term benefits and enhanced operational efficiency.

Must-Know Tips For Butterfly Check Valve Custom Solutions, Trusted by Pros

| Tip Category | Description | Recommended Material | Common Applications |

|---|---|---|---|

| Sizing | Choose the right size based on flow requirements and pressure drop. | Cast Iron, Stainless Steel | Water Treatment, HVAC Systems |

| End Connection Type | Select appropriate end connections such as flanged or threaded for easy installation. | PVC, Carbon Steel | Pumping Systems, Chemical Processing |

| Operating Pressure | Ensure valve is rated for the maximum operating pressure of the system. | Ductile Iron, Alloy Steel | Oil & Gas, Power Generation |

| Seal Type | Choose between soft or metal sealing based on application needs. | EPDM, PTFE | Food Processing, Pharmaceutical |

| Testing Standards | Ensure valves meet industry standards such as API, ANSI. | Stainless Steel, Bronze | Marine Applications, Fire Protection |

Ultimate Guide To Butterfly Check Valve Global Reach Now Trending

D

David Thompson

I am thoroughly impressed with the quality of the product. The attention to detail is truly exceptional.

24 July 2025

M

Maria Garcia

The product quality is outstanding! It’s durable and performs exceptionally well.

15 July 2025

J

Jennifer Scott

The product was delivered on time and in perfect condition. High-quality all around!

09 June 2025

T

Timothy Hall

I can’t believe how well this product is made. It’s clearly built to last.

25 June 2025

M

Michael Brown

Excellent quality overall! The support team showed remarkable professionalism in addressing my queries promptly.

05 June 2025

J

Jessica Taylor

Top-notch quality! The professionalism of the support staff made the entire purchasing experience seamless.

15 June 2025