Double Eccentric Butterfly Valve

Product description

Valve design to EN 593, EN1074-1/2, BS5155, DIN3354

Flange to EN 1092, BS4504, DIN2501, ISO7005, ASME B16.5, ASME B16.1, AWWA C207, AS4087

Face to face length to EN 558-1 / ISO 5752 series 14 / series 13, or other special length

♦ Stainless steel weld and finished body seat ensures a corrosion and wear resistant seat face.

♦ Streamlined low profiled disc design verified by finite element analysis ensures the higher strength and the lower flow resistance

♦ By means of seal gasket designed at joint between shaft bearing and disc, double O ring on shaft bearing and closed disc eyes, they form a dry operating condition for shaft and shaft seal to avoid the corrosion from service medium.

♦ Anti-blow out shaft design.

♦ Disc to shaft connection by means of taper pin or key(optional).

♦ Self-lubricating bearing in bronze or stainless steel lined PTFE reduce shaft friction and operating torque, the bearings keep the disc in center and prevent axial movements;

♦ Multiple O rings in shaft sealing system could prevent outleakage and dirt into. The O rings on packing gland and shaft cover could be replaced easily without removing the valve from pipeline.

♦ Suitable for full vacuum service conditions.

♦ T profiled resilient seal ring is secured on the disc by a retainer ring and bolts, and ensures reliable bi-directional sealing performance. The seal ring could be adjusted or replaced easily on site. Don’t need special tools.

♦ External locking device(Shaft lock/limit block) will be provided on the non-drive shaft ends, to enable the gear to be removed with the valve remaining in service in the open or closed position.

♦ Disc locking pin design is available as client’s request.

♦ Operated with gearbox + handwheel and with ISO 5210 top flange to be coupled with an electric actuator, if required at a later date.

♦ Gearbox with high mechanical advantage and low torque to adapt to various brands of electric actuator, such as Auma, Rotork & Bernard etc.

♦ Extension spindle from valve shaft or gearbox spindle are available as request.

♦ Valve externally and internally fusion bonded epoxy coated with a thickness of 250micron (different coating/lining is available as special request) and color code RAL5005/5015/5017.

♦ Suitable for the applications involving throttling service and for applications requiring valve actuation after long periods of inactivity.

Double Eccentric Butterfly Valve

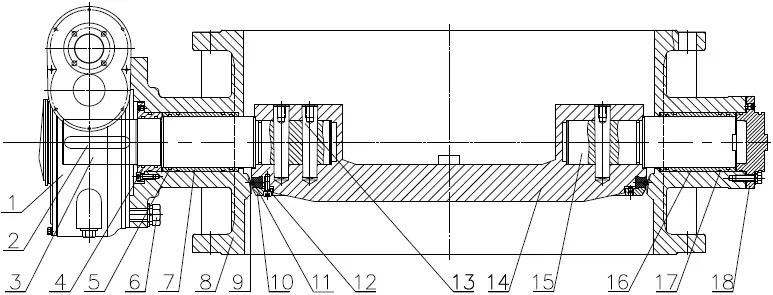

Materials of component

|

No |

NAME |

MATERIAL* |

SPECIFICATION |

REMARKS |

|

1 |

Gear housing |

Ductile Iron |

GJS450-10 |

|

|

2 |

Key |

Stainless Steel |

1.4021(SS420), 1.4057(SS431),17-4PH(SS630) |

|

|

Duplex Stainless Steel |

1.4462(S31803),1.4507(S32750) |

for rubber lined butterfly valve |

||

|

3 |

Upper Shaft |

Stainless Steel |

1.4021(SS420), 1.4057(SS431),17-4PH(SS630) |

|

|

Duplex Stainless Steel |

1.4462(S31803), 1.4507(S32750) |

for rubber lined butterfly valve |

||

|

4 |

Packing Gland |

Ductile Iron |

GJS500-7(GGG50), GJS400-15(GGG40) 65-45-12, 60-40-18 |

|

|

Carbon Steel |

1.0038(S235JR) |

|||

|

5 |

0 ring |

Rubber |

EPDM, NBR |

|

|

6 |

Bolt |

Stainless Steel |

A2-70(SS304), A4-70(SS316) |

|

|

Duplex Stainless Steel |

S31803, S32750 |

for rubber lined butterfly valve |

||

|

7 |

Shaft Bearing |

Bronze |

QAI9-2 CC331G |

|

|

8 |

Valve Body |

Ductile Iron |

GJS500-7(GGG50), GJS400-15(GGG40) 65-45-12, 60-40-18 |

|

|

Carbon steel |

1.0619(WCB) |

|||

|

9 |

Body Seat |

Stainless Steel |

Cr-Ni alloy / Ni welded |

|

|

10 |

Retainer Ring |

Carbon Steel |

1.0038(S235JR) |

|

|

Stainless Steel |

1.4301(SS304), 1.4401(SS316),1.4571(SS316Ti) |

|||

|

11 |

Disc Seal Ring |

Rubber |

EPDM, NBR, FKM, Silastic |

|

|

12 |

Screw |

Stainless Steel |

A2-70(SS304), A4-70(SS316) |

|

|

Duplex Stainless Steel |

S31803, S32750 |

for rubber lined butterfly valve |

||

|

13 |

Pin |

Stainless Steel |

1.4021(SS420) |

|

|

Duplex Stainless Steel |

1.4462(S31803),1.4507(S32750) |

for rubber lined butterfly valve |

||

|

14 |

Valve Disc |

Ductile Iron |

GJS500-7(GGG50), GJS400-15(GGG40) 65-45-12, 60-40-18 |

|

|

Carbon steel |

1.0619(WCB) |

|||

|

15 |

Lower Shaft |

Stainless Steel |

1.4021(SS420), 1.4057(SS431),17-4PH(SS630) |

|

|

Duplex Stainless Steel |

1.4462(S31803), 1.4507(S32750) |

for rubber lined butterfly valve |

||

|

16 |

Shaft Bearing |

Bronze |

QAI9-2 CC331G |

|

|

17 |

0 ring |

Rubber |

EPDM, NBR |

|

|

18 |

End Cover |

Ductile Iron |

GJS500-7(GGG50), GJS400-15(GGG40) 65-45-12, 60-40-18 |

(Other materials are available on request.)

★ Coating: fusion bonded epoxy coating, min. thickness 300 micron

★ Suitable medium: potable water, drinking water, sea water, TSE water, low-corrosive liquid etc.

★ Suitable temperature: 0 ~ 80 ℃

★ Pressure test to EN12266-1: Leakage rate: Class A (Zero leakage) in both direction

★ 100% testing before delivery

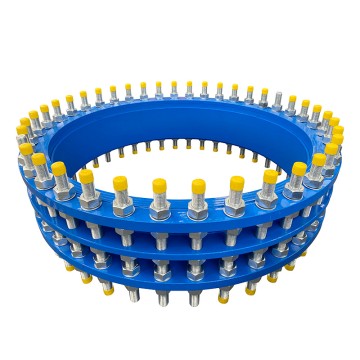

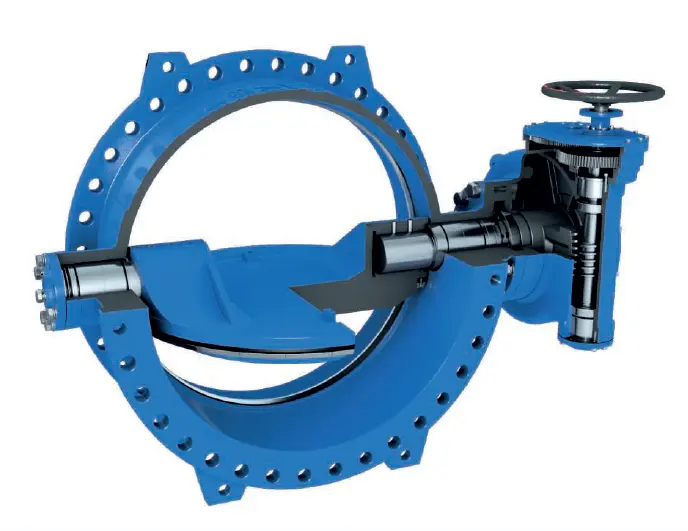

Product Display