Quality Flange Type Knife Gate Valves: Features, Benefits, and Expert Insights

The Flange Type Knife Gate Valve is a reliable solution for demanding industrial applications, providing exceptional sealing performance in the harshest environments. Engineered for durability, this valve has become a trusted choice among renowned manufacturers. At NEWSTAR VALVE (ZHENGZHOU) CO., LTD., we supply a competitively priced selection of these valves tailored to meet diverse requirements. Our comprehensive pricelist offers transparency, assisting you in making informed choices. Whether you're enhancing your facilities or initiating new projects, our Flange Type Knife Gate Valves ensure the quality and reliability you expect. Feel free to reach out for more information or specific size requirements; I'm here to help with any inquiries!

The Secret to Flange Type Knife Gate Valve Your End-to-End Solution Is The Best

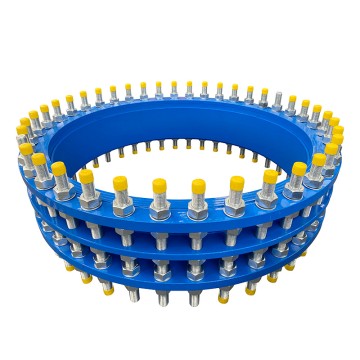

When it comes to industrial applications, the choice of valve can significantly impact operational efficiency and reliability. One such critical component is the Flange Type Knife Gate Valve, known for its ability to handle tough services, including slurries or other viscous media. What sets apart an effective solution is not just the valve's construction, but the entire process that encapsulates its design, manufacturing, and post-sale support. A comprehensive end-to-end solution means that the valve not only meets technical specifications but is also backed by a commitment to quality and service. At the core of a successful Flange Type Knife Gate Valve is robust engineering combined with precision manufacturing. This includes advanced materials and innovative design techniques that cater to a wide range of operational conditions. These valves are designed to provide exceptional sealing capabilities, minimizing leakage and ensuring a long service life even in challenging environments. Furthermore, a strategic approach to customization allows for adaptations that suit specific industry needs, enhancing both performance and safety. Global procurement managers should prioritize suppliers that offer a holistic view of their valve solutions, ensuring alignment with industry standards while providing responsive customer service. The best valve solution is not just about the product itself but the seamless integration of design, manufacturing, and after-sales support that guarantees performance excellence. By focusing on these aspects, companies can forge long-lasting relationships that drive mutual success in industry applications worldwide.

The Secret to Flange Type Knife Gate Valve Your End-to-End Solution Is The Best

| Dimension | Material | Pressure Rating | Temperature Range | Application |

|---|---|---|---|---|

| 2 inch | Cast Iron | 150 psi | -20°C to 80°C | Water Treatment |

| 4 inch | Stainless Steel | 300 psi | -10°C to 150°C | Chemical Processing |

| 6 inch | PVC | 200 psi | 0°C to 60°C | Wastewater Management |

| 8 inch | Ductile Iron | 150 psi | -20°C to 80°C | Hydraulic Systems |

| 10 inch | Carbon Steel | 350 psi | -40°C to 180°C | Oil & Gas |

Top 5 Flange Type Knife Gate Valve Where Innovation Meets 2025 From Concept to Delivery

G

Grace Turner

Highly satisfied with the product quality. The support team really knows their stuff and was incredibly responsive.

23 June 2025

B

Benjamin Nelson

An excellent purchase! The customer service staff were professional and extremely helpful throughout.

25 July 2025

A

Andrew Perez

Quality workmanship and fantastic after-sales service. The staff is knowledgeable and caring!

14 June 2025

E

Ella Thompson

Absolutely thrilled with this purchase. The quality is superb, and the support team was incredibly helpful.

10 July 2025

L

Lucas Young

Beyond satisfied with the product! The after-sales representatives were professional and attentive.

09 July 2025

A

Amy Martinez

Their customer support is truly world-class. They really know how to take care of their clients.

28 June 2025