Ball Valves, Gate Valves, and Butterfly Valves: A Complete Selection Guide

Introduction: Why Valve Selection Matters

Valves may look like small, simple components in a massive piping system, but they play a critical role in controlling, directing, and securing the flow of liquids and gases. Choosing the wrong valve can mean leaks, energy waste, safety hazards, and high maintenance costs. On the other hand, selecting the right valve type can extend equipment life, improve system efficiency, and even reduce downtime.

Among the many valve types available, ball valves, gate valves, and Butterfly Valves are the most common choices in industrial, municipal, and commercial projects. Each has its own strengths, limitations, and ideal application scenarios. But how do you know which one is best for your system?

This complete guide will walk you through how these three valves work, compare their advantages and disadvantages, and provide practical tips to help you make the right decision.

Understanding the Basics

Before diving into details, let’s quickly outline what makes these three valve types different:

Ball Valve: Uses a rotating ball with a hole to control flow. Known for quick shutoff and reliable sealing.

Gate Valve: Uses a sliding gate or wedge to completely stop or allow flow. Best for isolation, not regulation.

Butterfly Valve: Uses a rotating disc to control flow. Compact, lightweight, and cost-effective for large-diameter pipes.

With that foundation, let’s look more closely at how each valve works.

✅ Gate Valves: Reliable Flow Isolation

A Gate Valve operates by raising or lowering a flat or wedge-shaped gate inside the valve body. When the gate is fully lifted, the flow path is wide open with minimal resistance. When the gate is lowered, the flow is fully shut off.

Key Features

- Best for on/off control: Gate Valves are designed primarily for full open or full closed service.

- Minimal pressure drop: Once fully open, the flow passes through almost unobstructed.

- Slow operation: Turning the handwheel to move the gate up or down takes time, making them less ideal for quick shutoff needs.

Pros

- Excellent sealing performance for complete isolation.

- Suitable for high-pressure and high-temperature applications.

- Long service life when used properly.

Cons

- Not suitable for throttling or flow regulation. Partially opening the gate can cause vibration and erosion.

- Relatively slow to operate.

- Larger and heavier than Butterfly Valves.

Common Applications

- Municipal water supply systems.

- Oil and gas pipelines.

- Power plants and industrial facilities requiring reliable shutoff.

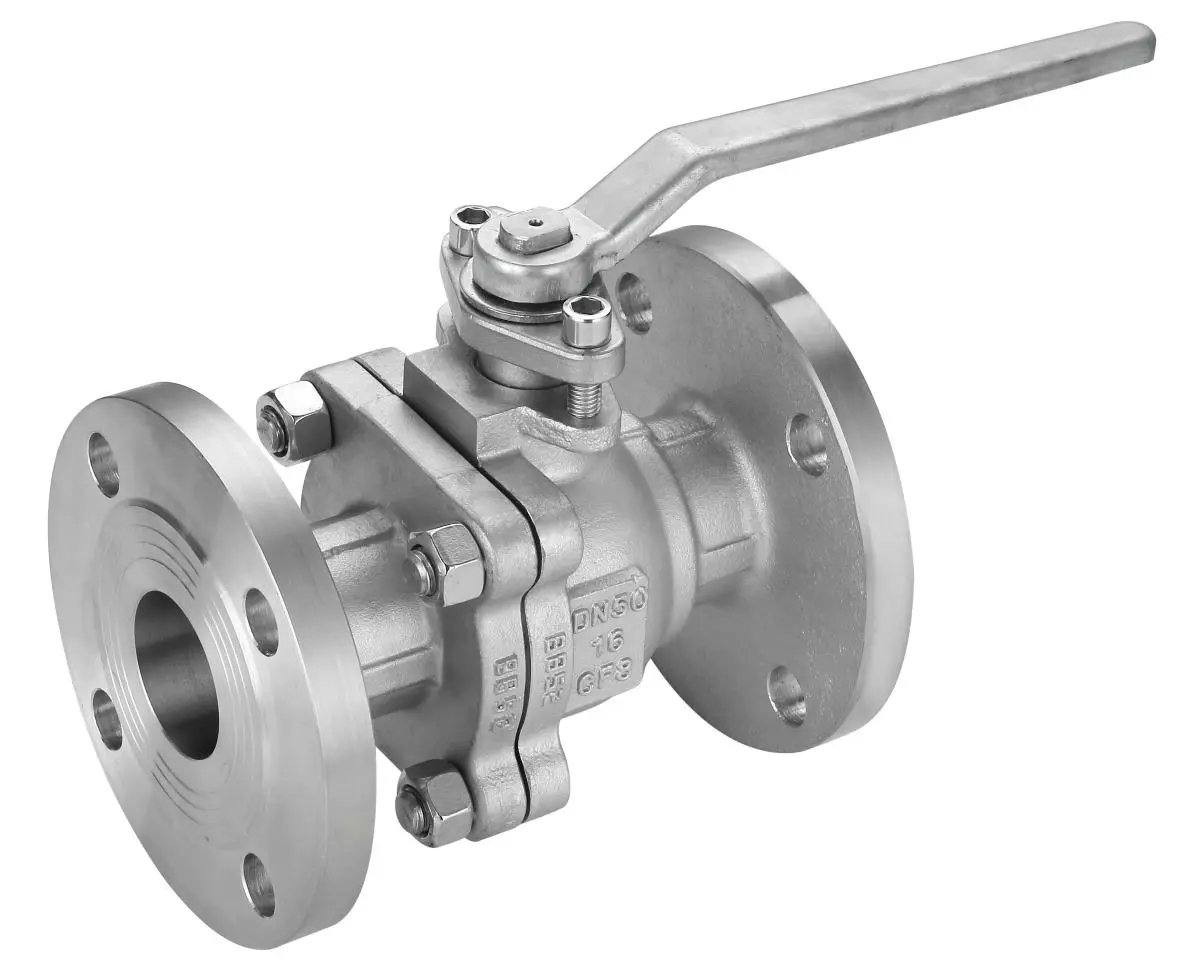

✅ Ball Valves: Quick and Efficient Control

A ball valve controls flow using a rotating sphere with a hole drilled through its center. When the hole aligns with the pipeline, the valve is open; when rotated 90 degrees, the valve shuts completely.

Key Features

- Fast shutoff: A quarter-turn is enough to open or close the valve.

- Tight sealing: Ball valves provide excellent leak-proof performance, even under high pressure.

- Flexible control: Can be used for both isolation and limited flow regulation.

Pros

- Quick and easy operation.

- Compact design compared to Gate Valves.

- Available in soft-seated and metal-seated versions for different media.

- Durable and low maintenance.

Cons

- Heavier and more expensive than Butterfly Valves in larger sizes.

- Not always the best option for precise throttling.

- May require more torque for operation in high-pressure systems.

Common Applications

- Oil, gas, and chemical industries.

- Food and beverage production.

- Automation systems requiring frequent valve operation.

- Residential plumbing and HVAC systems.

✅ Butterfly Valves: Lightweight and Cost-Effective

A butterfly valve regulates flow using a rotating disc positioned in the center of the pipe. When the disc is parallel to the flow, the valve is open; when perpendicular, it blocks the passage.

Key Features

- Compact and lightweight: Much smaller and easier to install compared to gate or ball valves of the same size.

- Quick operation: Like ball valves, butterfly valves require only a quarter-turn.

- Economical choice: Lower cost, especially for large-diameter applications.

Pros

- Space-saving and easy to install.

- Energy-efficient due to lightweight design.

- Good corrosion resistance when fitted with appropriate lining materials.

- Cost-effective for large-scale projects.

Cons

- Less precise in flow regulation compared to ball valves.

- Disc remains in the flow path, causing some pressure drop.

- May not handle very high pressure or temperature as well as gate or ball valves.

Common Applications

- Water treatment and wastewater plants.

- HVAC systems.

- Chemical and pharmaceutical industries.

- Marine and desalination projects.

Choosing the Right Valve: A Practical Guide

When faced with a project decision, keep these factors in mind to make the right choice:

✅ Type of Fluid and Environment

- Corrosive fluids: Consider lined butterfly valves or stainless-steel ball valves.

- High-pressure systems: Gate valves or ball valves are better suited.

- Clean water or low-pressure flow: Butterfly valves often provide the most economical solution.

✅ Frequency of Operation

- For frequent on/off switching, choose ball valves or butterfly valves for their quick operation.

- For infrequent operation where isolation is the main goal, gate valves are a strong option.

✅ Need for Flow Regulation

- If precise throttling is required, ball valves are superior.

- Gate valves should generally be avoided for regulation.

- Butterfly valves can provide rough flow control but lack precision.

✅ Installation Space

- Tight spaces benefit from compact butterfly valves.

- Ball valves are also relatively compact, while gate valves take up more room.

✅ Budget Considerations

- Butterfly valves are the most cost-effective for large diameters.

- Ball valves may cost more but provide durability and versatility.

- Gate valves, while durable, can be more expensive to install and maintain.

Comparison Table

| Feature | Gate Valve | Ball Valve | Butterfly Valve |

| Operation | Multi-turn | Quarter-turn | Quarter-turn |

| Best Use | Isolation only | Isolation+control | Large diameter,low pressure |

| Flow Resistance | Very low | low | Moderate |

| Pressure/Temperature | High | High | Medium |

| Size/Weight | Large, heavy | Medium | Compact,lightweight |

| Cost(large diameters) | High | High | Low |

Conclusion: Matching Valves to Your Needs

There is no one-size-fits-all valve. Gate valves, ball valves, and butterfly valves each serve specific purposes, and the right choice depends on your system’s requirements.

By understanding these differences, you can make informed decisions that improve your project’s efficiency, safety, and cost-effectiveness. The right valve is not just a piece of hardware—it’s an investment in the long-term performance of your system.